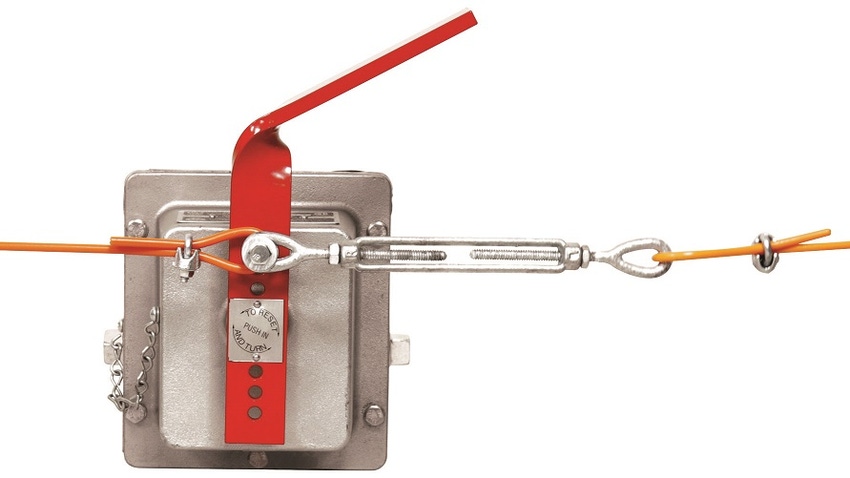

Safety Stop Switch Detects Cable Breaks

April 22, 2019

The Model RSB is a “broken-cable” version of the Model RS series of cable operated safety stop switches. This unit is designed to actuate whenever the actuation cable is severed or pulled. It was developed to meet the stringent requirements of safety agencies throughout the world.

This control is designed to act as an emergency stop for conveyors and other moving machinery. The Model RSB is known as a “double-ended” unit and has an external extension spring at the end of each cable run, which maintains constant tension on the pull cable. The spring also helps to compensate for expansion and contraction of the pull cable due to temperature fluctuations. The operating handle is held in the vertical position, using a turn-buckle for adjustment. If the cable is pulled or breaks, the handle rotates and activates the microswitch. In this way, the alarm signal is generated for both conditions: cable pull or cable break. The operating handle must then be manually reset back to the center position after the problem has been corrected.

Conveyor Components Co., Croswell, MI 810-679-4211 www.conveyorcomponents.com

For related articles, news, and equipment reviews, visit our Mechanical Conveying Equipment Zone

Click here for Mechanical Conveying Equipment Manufacturers

Get information or register for Powder Show Toronto, June 4-6, 2019

You May Also Like