Particle Size of Mineral Pigment and Color Hiding Power

This application note explores the in-depth study of the correlation between the particle size of mineral pigments and the hiding power, as well as the chromatic gradation of their color.

June 14, 2023

Feiqing Shen, assistant application engineer, Bettersize Instruments.

Particle size variation in mineral pigments leads to different hiding power, attributed to the light scattering effect. It results in smoother transitions between colors and a richer chromatic gradation of pigments. The laser particle size analyzer used in this research enables the detection and control of this physical phenomenon. This application note provides a method to measure particle size to optimize pigment formulations and achieve desired color effects across many fields.

Introduction

Hiding power, also referred to as hiding strength or coverage, is a term used to describe the ability of a coating or pigment to conceal the underlying surface or previous layers. It quantifies the effectiveness of the coating or pigment in obscuring the color or pattern of the substrate. Hiding power is an important property in various industries, particularly in the paint, coatings, and printing industries. It determines the efficiency of a coating in achieving the desired color and appearance, as well as its ability to mask imperfections and inconsistencies on the surface. Manufacturers and consumers prioritize coatings with higher hiding power due to their ability to provide optimal coverage and ensure a satisfactory result.

The hiding power of mineral pigment is related to the particle size of the pigment particles. Generally, the smaller the particle size, the better the hiding power. This is because smaller particles can fill the fine imperfections and unevenness of the surface more effectively, resulting in a smoother and more uniform coating. Additionally, smaller particles can enhance the hiding power of paint by facilitating a stronger scattering effect of light on the particle surface. This increased scattering and reflection of light reduces the possibility of light penetrating through the coating, resulting in better hiding strength, color consistency, and seamless chromatic gradation of the pigment.

Materials and Methods

This experiment aims to analyze the impact of particle size of mineral paint on the hiding power. In this application note, the particle size distribution of the pigments is measured using a laser particle size analyzer. The laser diffraction method used in this instrument enables precise and efficient characterization of particle sizes in various industries and research fields by analyzing the scattering pattern of laser light.

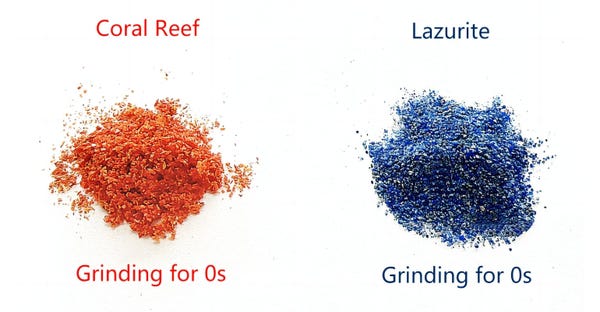

The materials involved in the experiment include raw coral reef and lazurite. By controlling different grinding times, several samples with varying particle size distributions are obtained. Finally, the hiding power of these pigment samples can be determined by employing standard method in ASTM D6441-05 to ascertain the relationship between the coverage and the particle size of the mineral pigment.

Result and Discussion

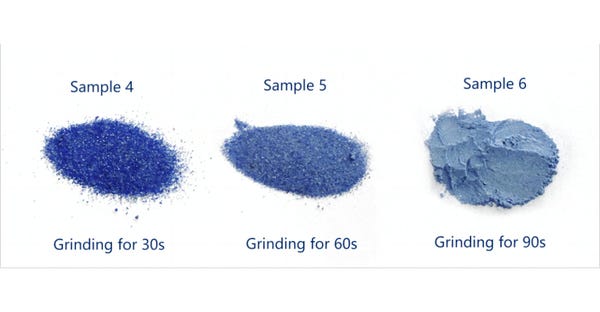

Grinding Result: The result of raw coral reef and lazurite with different grinding times is shown in Figures 1, 2, and 3. By varying the grinding time, samples with diverse particle size distributions can be obtained. As the grinding time increases, the particle size of the samples decreases, which changes visibly evident in their color characteristics. Figure 2 illustrates three coral reef samples derived from the same initial sample but differing only in grinding time. It is observed that Sample 1, ground efficiently for 30 seconds, exhibits the coarsest particles with the highest color saturation but the lowest brightness. Conversely, Sample 3, ground for 90 seconds, displays the finest particles with the lowest color saturation but the highest brightness. The same conclusion can be drawn from the lazurite depicted in Figure 3.

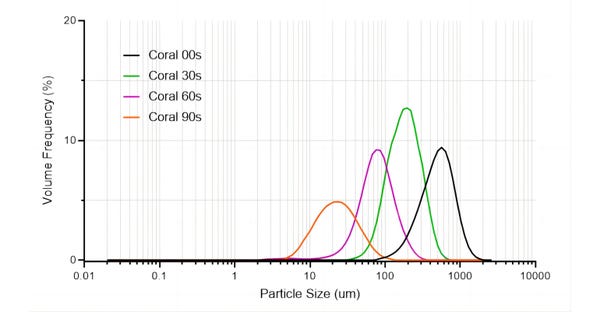

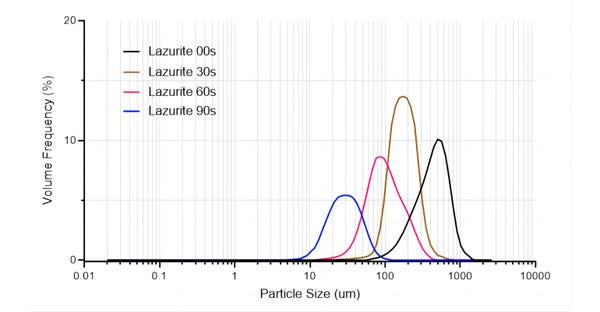

Particle Size Result: Figure 4 and Figure 5 provide the particle size distribution of ground coral reef and lazurite, each for 0 seconds, 30 seconds, 60 seconds, and 90 seconds. The particle size distribution of these two mineral pigments shows a very similar trend that can also be observed in Table 1 and Table 2.

Table 1. Typical particle size values of three coral samples

Sample | Dv10(μm) | Dv50(μm) | Dv90(μm) |

Coral 00s | 221.8 | 473.2 | 841.8 |

Coral 30s | 101.9 | 177.6 | 301.4 |

Coral 60s | 34.47 | 72.43 | 137.3 |

Coral 90s | 7.674 | 21.33 | 73.38 |

Table 2. Typical particle size values of three lazurite samples

Sample | Dv10(μm) | Dv50(μm) | Dv90(μm) |

Lazurite 00s | 189.2 | 413.7 | 689.1 |

Lazurite 30s | 106.3 | 161.6 | 239.8 |

Lazurite 60s | 46.76 | 89.58 | 196.3 |

Lazurite 90s | 13.08 | 28.61 | 53.75 |

Hiding Power Result: The hiding power of these pigment samples, which refers to the ability of a pigment to effectively conceal the substrate underneath it, is measured by applying the standard method outlined in ASTM D6441-05. In this method, after painting the pigment onto smooth, glossy test panels divided equally into black and white areas with a straight boundary, the coverage of the pigment can be visually evaluated as shown in Figure 6. To obtain an accurate percentage, it is necessary to use a testing instrument to measure the hiding power of the samples.

Figure 6: Example of hiding power 50% vs. 100%

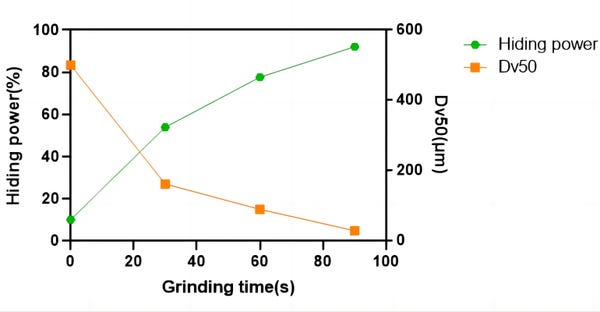

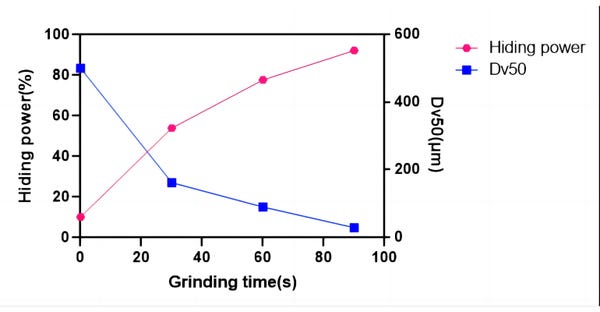

The correlation curves between hiding power, median particle size Dv50, and grinding time for coral and lazurite are shown in Figure 7 and Figure 8. Mineral pigments composed of coarse particles generally exhibit higher color saturation and lower lightness, resulting in weaker hiding strength. In contrast, fine particle pigments, due to their smaller size, can better fill the paint surface, resulting in a more uniform color and stronger hiding strength.

From the trends observed in these two graphs, it can also be concluded that once the particle size reaches a certain small value, the hiding power will approach 100%, which means that further grinding cannot significantly change the coverage exhibited by the pigment. Therefore, by utilizing the laser particle size analyzer, this critical particle size threshold value can be determined, enabling the avoidance of unnecessary grinding in industrial processes and thus lower milling costs.

By comparing and analyzing the results of these two mineral samples, instead of one pigment, this experiment validates the universality of the impact of particle size on hiding power across different types of minerals. This association is not limited to one specific type of minerals but has broader applicability, which further strengthens the understanding of this correlation.

For various types of mineral materials, different particle size range shows corresponding hiding strength. Therefore, the laser particle size analyzer can provide meticulous measurement of the granularity and support in finding the optimal balance between particle size and desired coverage, ensuring consistency in products.

Conclusion

This application note explores the in-depth study of the correlation between the particle size of mineral pigments and the hiding power, as well as the chromatic gradation of their color. As a result, it can assist customers in the fields of coatings, pigments, paints, and related industries to detect improve the formulation of coatings, ultimately resulting in enhanced coatings with precise control in manufacturing and production.

Feiqing Shen is assistant application engineer, Bettersize Instruments. For more information, call 833-699-7493 or visit www.bettersizeinstruments.com.

You May Also Like