Developing New Anti-Caking Agents: Using Powder Testing to Identify High-Performance Candidates

Collaborative work on new anti-caking agents carried out by Omya and Freeman Technology

October 25, 2021

Laura Shaw, Freeman Technology; Dr Renata Negrini, Omya International AG; Marcel Lex, Omya International AG; Jamie Clayton, Freeman Technology; Lalit Sharma, Omya International AG

The food processing and handling industry is heavily reliant on anti-caking agents to safeguard manufacturing efficiency and preserve the value of powdered ingredients and products. Driven by innovation and evolving customer preferences, this is an industry showing healthy expansion with the food handling and processing equipment market predicted to exhibit a compound annual growth rate (CAGR) of 6.5% up to 2026.1

Against this backdrop there is rising demand for new, high-performance additives that meet changing needs, notably to displace ingredients that are controversial or of undesirable provenance. For example, silica is an effective, widely used anti-caking agent but use is becoming increasingly controversial due to concerns over nanoparticles.2

In this article we describe collaborative work on new anti-caking agents carried out by Omya (Oftringen, Switzerland) a leading global producer of calcium carbonate, and Freeman Technology (Tewkesbury, UK) a global leader in powder characterization technology. A primary focus is the application of advanced powder testing (FT4 Powder Rheometer) to assess heterogeneous caking behavior – crusting – to rigorously assess potential candidates.

The Caking of Food Ingredients: Mechanisms and Impact

Powders left undisturbed for protracted periods of time can gain strength, losing the flow properties that in many instances define their value. This process is known as caking and it can proceed via a range of chemical, electrical, and mechanical mechanisms; with food ingredients the absorption and migration of moisture almost always plays a defining role. The adsorption of moisture on to the surface of powder particles, or into the powder bulk, can trigger chemical caking – for example by hydration, partial dissolution, and recrystallization - or induce plastic flow, through modification of the particle surface and, by extension, particle-particle interactions. Multiple mechanisms may occur simultaneously or sequentially, and the net result varies from soft easily broken aggregates to irreversibly fused material with properties far removed from those of the original material.

Powdered ingredients used by the food industry range from dry ground spices and extracted flavorings to core ingredients such as cocoa and milk powders. Such ingredients exhibit considerable diversity with respect to surface chemistry and physical properties and caking behavior is correspondingly complex. For any given material, the uptake of moisture is directly influenced by storage conditions (relative humidity, temperature, and pressure) but stored powders typically only have one surface exposed to the surrounding environment. Caking behavior is therefore complicated by the ease or otherwise of moisture migration through the powder, even as the properties of the powder bed are modified by, for example, liquid bridging or recrystallization. The assumption that caking is always homogeneous is unreliable; crusting is commonplace.

The consistent processing and ease-of-use of powdered ingredients is reliant on their flow properties, with caking potentially impacting critical operations such as hopper discharge, blending, dosing and, in certain instances, dissolution. Controlling caking to acceptable levels is therefore crucial. The goal is to establish strategies that maintain ingredients in an optimal state without incurring unnecessary expense. While storage under conditions of controlled temperature and humidity may be essential, anti-caking agents can transform sensitivity to moisture, making flow properties much easier to maintain. As a result, they are a vital class of additive for the food industry.

Developing New Anti-Caking Agents

The provenance and safety of food ingredients is constantly under review and is an important driver for innovation and reformulation. With respect to anti-caking agents, silica is often considered the “gold standard” with potential to reduce caking by:

dispersing sparingly across particle surfaces, thereby increasing the distance between particles, and decreasing van der Waals forces of attraction

absorbing moisture to reduce the effect of liquid bridging

completely coating particles to prevent adhesion.

Via these mechanisms, incorporating silica at different concentrations can improve the caking behavior of all types of powder - dry/hard, moist, and soft/high fat materials, respectively. However, the use of silica is becoming more controversial. Silica anti-caking agents have a fine particle size distribution to impart the high specific surface area that underpins their efficacy. Though typically made up of aggregated nanoparticles with a diameter in excess of 100 nm there is concern that the material potentially subjects users to exposure to particles below this “nano threshold.” Regulations over nanoparticles and the potential health risk associated with them continue to evolve but some countries have now banned silica as an anti-caking agent with the European Food Safety Authority (EFSA), for instance, calling for better characterization and specification to provide an assurance of safety.2

The status of silica provides impetus for the introduction of new anti-caking agents with a more robust safety profile. Calcium carbonate has considerable potential in this respect. A natural material with an established safety profile, it is already used to fortify foods, including dairy and non-dairy drinks. Replicating the impressive performance of silica is a significant challenge but Omya has made considerable progress in this regard, drawing on its expertise in calcium carbonate product development. The following studies illustrate the levels of performance achieved with new functionalized calcium carbonate (FCC) anti-caking agents.

Assessing the Performance of Anti-Caking Agents

The purpose of anti-caking agents is to preserve the flow properties of powders. Comparative assessments of the performance of new anti-caking agents therefore rely on the measurement of powder flowability. Dynamic powder testing with a powder rheometer is uniquely suitable for this purpose because it offers:

high sensitivity: enabling the detection of even subtle differences in caking behavior

relevance: test conditions can be selected to assess the impact of environmental conditions and consolidation, for example, and dynamic properties have been securely correlated with performance in many unit operations such as blending, conveying and discharge

the ability to characterize heterogeneous caking behavior or crusting.3

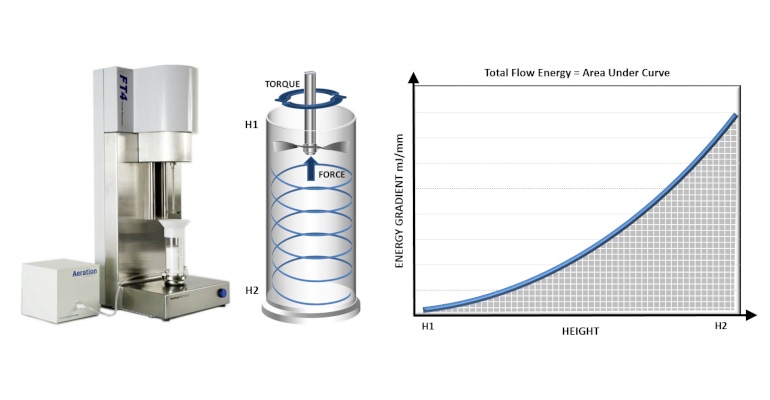

The figure at the beginning of this article shows how Basic Flowability Energy (BFE), a baseline dynamic powder property is measured using the FT4 Powder Rheometer. The axial and rotational forces acting on the blade of the instrument are recorded every 40 ms as it rotates down through the powder bed, to construct a plot of energy gradient as a function of bed height. Values of BFE are generated by integration, by determining the area under the curve. However, differences in flow characteristics within the sample are easily detected since the position of the blade can be determined with a high degree of accuracy, at any given time. With dynamic testing it is possible to detect crusting, to track the impact of moisture migration through the powder bed, and to quantify the strength of aggregated material. Via humidity cycling experiments it is also possible to determine whether caking is reversible. These capabilities make dynamic testing extremely valuable for all types of caking studies.

Case Study 1: Comparing the Performance of New Anti-Caking Agents

An experimental study was carried out to compare the performance of two FCC anti-caking agents, Agent 1 and Agent 2, with that of a commercially available silica product. Dynamic powder properties were measured for four samples: milk powder and milk powder with 1% w/w silica, 1% w/w Agent 1, and 1% w/w Agent 2. Baseline powder characterization tests were carried out under ambient conditions (FT4 Powder Rheometer) and caking behavior was then quantified via repeat testing following storage under conditions of controlled relative humidity, after 4½ days at 63% RH and after 2½ days at 74% RH.

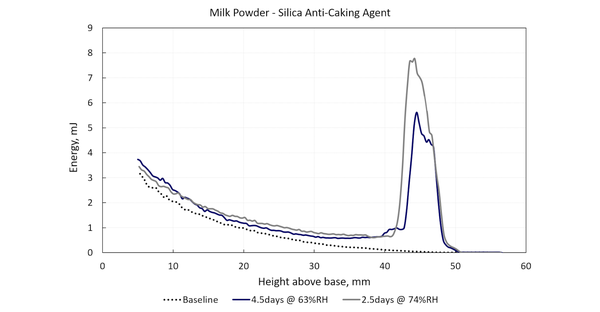

In an initial analysis of the data Caking Index (CI) was determined, where CI is the ratio of the Total Energy (TE) of the caked material to the BFE of the fresh powder before storage. The CI of the sample containing the silica anti-caking agent was found to be unexpectedly high given that the silica was known to be effective in preventing caking. Figure 1 shows the data that underpin these calculations.

Figure 1: A plot of energy as a function of height for the milk sample containing the silica anti-caking agent shows clear evidence of crusting.

These results show evidence of crusting in the top ~10 mm sample after storage for 4½ days at an RH of 63%, with the peak of the graph indicating greater resistance to flow in this area. Storage at the higher RH (74%) produces a stronger crust in a shorter timeframe. However, in both cases the crust is relatively thin and the material beneath is unchanged with respect to flow characteristics; both traces return close to the baseline curve.

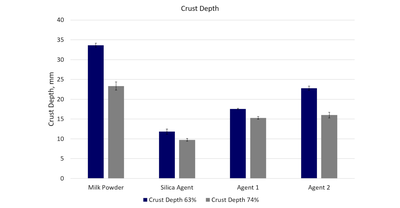

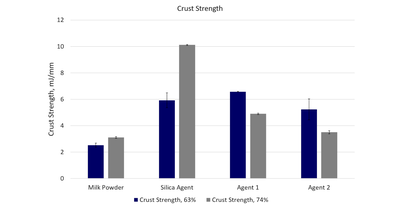

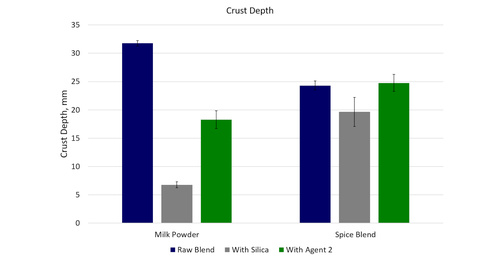

Figure 2: Crust depth and strength data for the four samples indicate that the new anti-caking agents result in a thicker but weaker crust compared with the silica product.

Comparable data for each of the samples quantify differences in crust depth and strength (see figure 2). In the absence of anti-caking agents, the milk powder cakes extensively, to a depth of ~23-33 mm, depending on storage conditions, though the caked material has relatively little strength. The crust that develops with Agent 1 and Agent 2 is thinner than in the absence of an anti-caking agent but thick relative to silica particularly after storage at the low RH (63%). However, the strength of crust developed at high RH with Agents 1 and 2 is lower than with silica; at lower RH the strength of the developed crust is more comparable.

These data suggest that all the anti-caking agents promote the formation of a relatively impermeable crust at the air-powder interface that inhibits moisture migration into the rest of the powder. They also provide evidence that the new agents perform relatively well compared with the silica leading to the formation of a thicker crust with comparable or lower strength, depending on storage conditions.

In a final extension to the study, the observed caking parameters were correlated with the properties of the freshly blended samples, measured under ambient conditions prior to caking, to investigate the feasibility of predicting caking behavior from this baseline analysis. This analysis revealed two particularly strong and interesting relationships:

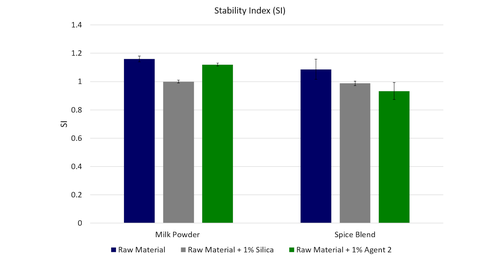

* Crust depth was found to correlate strongly with Stability Index (SI - R2, 63% RH = 0.9542, 74% RH = 0.9267), where SI is the ratio of BFE measured after seven measurement cycles to initial BFE. Instability in BFE measurements is potentially due to moisture uptake during measurement, providing a rationale for this correlation.

* The maximum energy in the crust, an indicator of crust strength was found to correlate strongly with permeability as quantified by pressure drop across the sample at 15 kPa (R2, 63% RH = 0.8954, 74% RH = 0.9570). A rationale for this relationship is that low permeability inhibits moisture migration promoting the development of a stronger crust at the air-powder interface.

Taken together the results from this study show how dynamic data can sensitively characterize and differentiate Agent 1 and Agent 2 via multiple, relevant metrics, to provide an assessment of their performance relative to silica, with some potential to predict behavior. This contrasts markedly with alternative techniques, such as moisture uptake measurements, which provided no differentiation between Agent 1 and Agent 2 and far more limited insight.

Case Study 2: Comparing Caking Behavior in Different Substrates

A second set of experiments was carried out to compare the performance of anti-caking agents with two different substrates: milk powder and a commercial spice blend. Dynamic powder properties were measured (as in case study 1) for the raw powders and for blends of each powder with 1% w/w of either silica or Agent 2. Baseline characterization was carried out under ambient conditions and caking behavior was quantified via repeat testing following storage at 75% RH for two days and six days, for the milk and spice samples, respectively. This reflects the storage times required for significant crust formation to be observed for each substrate.

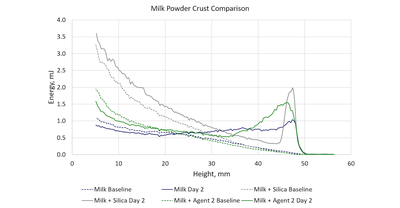

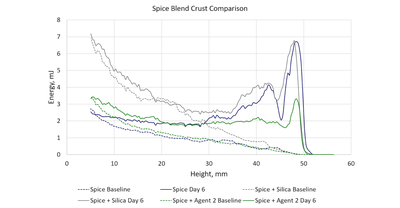

Figure 3: Plots of energy as a function of height for the milk (left) and spice (right) samples, with and without the anti-caking agents show that substrate has a significant impact on caking behavior.

Data for the milk powder (figure 3 – left) are comparable to those generated in case study 1, as expected. However, different behavior is observed with the spice blend (figure 3 – right). Here silica limits caking to the top half of the sample but baseline energy values of the silica-spice blend are significantly higher than either the raw material or the Agent 2 blend. Furthermore, while both the raw spice and Agent 2 blend exhibit a clear peak energy value, flowability fails to converge to the baseline value in either case; energy values are higher after storage throughout the entire sample. This caking behavior could be described as hybrid, somewhere between crusting and uniform caking throughout the powder sample and indicates that with the spice blend a greater proportion of the powder bed will be affected by any caking that occurs.

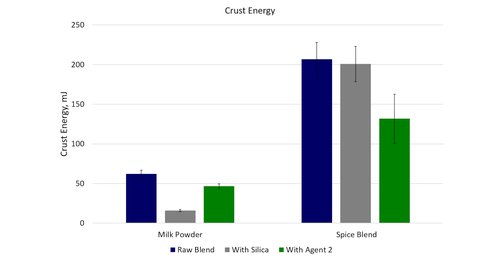

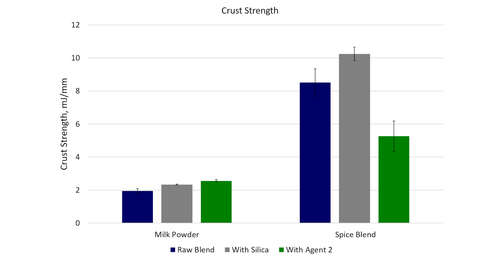

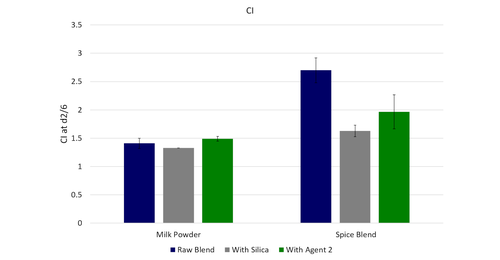

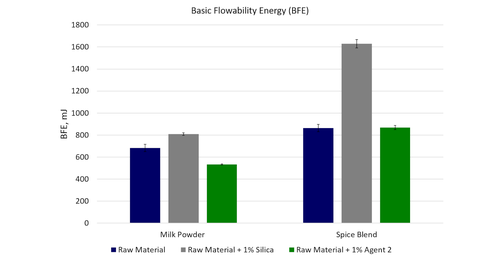

Figure 4: Dynamic data measured for the milk and spice blend show that the effect of anti-caking agents depends on substrate.

A complete comparison of data for the two substrates in the presence and absence of silica and Agent 2 demonstrates notable differences. In general, far stronger crusts form with the spice blend, relative to the milk powder. However, Agent 2 reduces crust energy and strength significantly, relative to silica; the associated increase in crust depth is less marked. Agent 2 has a positive impact on CI for the spice blend, relative to the absence of a caking agent, though silica gives the lowest CI value.

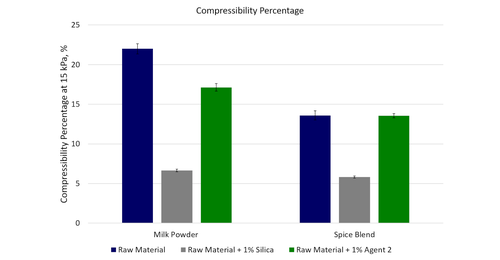

As in case study 1, this set of experiments was expanded with an analysis of dynamic and bulk properties of the fresh blends, prior to storage. These data (figure 5) illustrate how the inclusion of anti-caking agents impacts the properties of the raw powders, providing useful insight with respect to the potential for changes in process performance, as well as helping to rationalize observed caking behavior.

Figure 5: Dynamic and bulk properties for the milk and spice blends show that the impact of the anti-caking agents varies significantly with substrate.

The inclusion of silica substantially reduces the compressibility of both the milk powder and the spice blend. Agent 2 reduces the compressibility of the milk powder, though not the spice blend, and to a lesser extent than the silica. Lower compressibility is associated with more efficient particle packing and makes powders less prone to changes in flowability during storage. However, it can also give rise to high BFE values, since less compressible powders tend to flow poorly under the forcing conditions associated with BFE measurement. This effect is observed with the spice-silica blend, though not so much with the analogous milk powder sample. Strong correlations were observed between compressibility and CE (caked energy) (R2, milk powder = 0.9981, R2, spice blend = 0.9275).

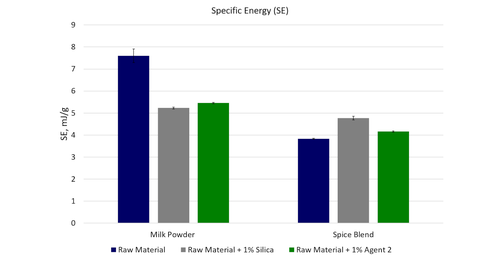

SE data provide a further example of the contrasting behavior observed with different substrates. While both anti-caking agents reduce the SE of the milk powder the opposite effect is observed with the spice blend. SE quantifies how easily the powder flows when in an unconfined, low stress state. Higher values may therefore be directly associated with compromised performance in unit operations where the powder is flowing under gravity, for example, in filling or dosing applications.

Finally, as in case study 1 a strong correlation was observed between SI and crust energy (R2, milk powder = 0.9970, R2, spice blend = 0.9860), for both powders, and it is reasonable to rationalize this trend as before, with reference to the ability of SI to provide an indication of propensity for moisture uptake.

This second set of data provides further evidence of the complexity of caking behavior and the insight generated by dynamic powder properties, into crusting and the relative suitability of different anti-caking agents for different substrates.

Looking Ahead

The food processing industry relies heavily on anti-caking agents to achieve the manufacturing efficiency and product performance required. Improving and refreshing the additive portfolio is vital in response to changing requirements, to formulate new foods and to eliminate ingredients with an undesirable provenance or health profile. The work presented here demonstrates the value of dynamic powder testing for comparing the performance of anti-caking agents and the efficacy of new functionalized calcium carbonate anti-caking agents, with two different substrates. A crucial feature of dynamic testing is the ability to detect and characterize non-homogeneous caking or crusting to provide unique and rigorous insights that directly support the introduction of additives with a target performance profile. The results generated show that functionalized calcium carbonate anti-caking agents deliver performance approaching that of silica--a gold standard anti-caking agent--thereby demonstrating considerable potential for food processing applications.

Laura Shaw is applications specialist, Freeman Technology; Dr. Renata Negrini is technical service manager food, Omya International AG; Marcel Lexis former innovation engineer consumer goods, Omya International AG; Jamie Clayton is operations director, Freeman Technology; Lalit Sharma is innovation manager food, Omya International AG.

References

1 McKinsey and Co. “Food Processing and Handling: Ripe for Disruption”

2 N Michail “EFSA raise red flag for silicon dioxide safety over nanoparticles”

3 Brockbank K, Armstrong B, Clayton J. Measurement and quantification of caking in excipients and food products with emphasis on the non-homogeneous interaction with ambient moisture. Particuology 2020, 56: 75-83

You May Also Like