Powerful turnkey system offers continuous pharmaceutical processes

July 7, 2022

Coperion K-Tron announces its partnership with process automation and software experts Emerson and Continua Process Systems to provide highly versatile, turnkey continuous direct compression skids for pharmaceutical and biotech manufacturers.

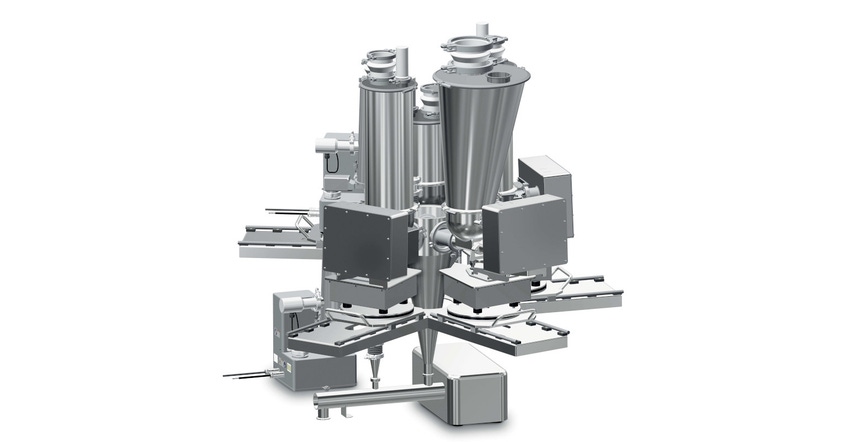

These ultramodern modular skids are state-of-the-art fully integrated platforms that include all the hardware and software necessary for a complete direct compression tableting continuous manufacturing line. The platforms are designed for complete modularity of the hardware and software to allow end users the flexibility to select different processes including dry and wet granulation, different unit operations, and the ability to manufacture multiple products on a single skid.

“The collaboration between the three companies has offered each of us to contribute our own state-of-the-art design, technologies, and process strengths for a completely modular, and versatile footprint, which in turn will enable further adoption and growth for continuous processing applications in the pharmaceutical industry,” said Sharon Nowak, global business development manager for Coperion’s food and pharmaceutical business.

Top Features

The custom-built direct compression skid includes automatic powder dispensing via up to six loss-in-weight (LIW) Coperion K-Tron feeders, combined with the end users’ blender and tablet press of choice. The process automation and orchestration are controlled by an Emerson DeltaV distributed control system (DCS) with Continua’s ContinuousPlant software suite application platform that provides for faster, simpler, and less costly systems integration between feeders, blender, and subsequent unit operations using the OPC-UA data exchange standard for digitally connected systems.

The Emerson’s DeltaV DCS ensures quality, compliance, and optimized implementation in a cost-effective continuous manufacturing line. From applying automation during process development to collecting data with context during manufacturing, the DeltaV technology and manufacturing systems software solutions can improve data management, real-time product quality, reliability, and operating costs. Emerson’s solutions for process analytical technology (PAT)-based manufacturing help streamline continuous processes by integrating multivariate data and real-time process models to manage critical quality attributes and predict final product quality at any time.

Coperion K-Tron Salina Inc., Salina, KS 785-825-3830 www.coperion.com

About the Author(s)

You May Also Like