Feeders 52

December 5, 2006

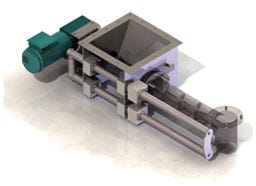

Quick-Take-Apart Volumetric Feeder

Quick-Take-Apart Volumetric Feeder

This volumetric feeder can be taken apart with auger removal from either end. All removable parts are secured with hand knobs, making disassembly simple and tool-free. Slide bars mounted in linear bearings provide easy operator interface by supporting the discharge tube and drive assembly. Features include a hard-chromed shaft seal journal with an air purge seal, an overflight agitator, a heavy-duty main housing free of ledges, and an EZ slider-component assist mechanism. The modular design allows for sliding hinge assemblies and field change of auger size and the discharge tube.

HAF Equipment Inc., Centerville, MN 651-653-5098 www.hafequipment.com Mass-Flow Feeder

Mass-Flow Feeder

The mass-flow feeder is a controllable high-capacity gravity feeder for relatively coarse granular materials that consists of a mass-flow hopper with two movable sides. The discharge rate is controlled by synchronous rotation of the movable sides. The flow rate is a function of the discharge opening width and the slope of the blades. Minimum flow rate is limited by the opening width at which the material arches across the opening. Turndown rates of 10 to 1 can normally be expected.

Pebco Inc., Paducah, KY 270-442-1996 www.pebco.com Force-Measurement Suspension System

Force-Measurement Suspension System

A force-measurement suspension system (FMSS) provides high accuracy in measuring weight using conveyor belt scales, weigh belt feeders, and loss-in-weight feeders. Available in a number of capacity ranges and configurations to suit the particular needs of continuous weighing and feeding equipment, the system has proven effective in high-speed, high-volume to low-density, low-rate applications where control quality and productivity are critical. By providing mass counterbalance of tare weight, it creates a superior signal-to-noise ratio in weight sensing that allows for precise real-time measurements.

Thayer Scale–Hyer Industries Inc., Pembroke, MA 781-826-8101 www.ThayerScale.com

Volumetric and Gravimetric Feeders

Volumetric and Gravimetric Feeders

Mechatron LC feeders are ideally suited for feeding dry minor ingredients at rates as low as 0.002 cu ft/hr. Features includes an AC drive package and a Coni-Flex flexible conical hopper. The feeders can be disassembled, cleaned, reconfigured, and serviced from the nonprocess side of the feeder. They are available in both volumetric and gravimetric models with accuracies up to ±¼% of the feed rate setpoint at 2 sigma.

Schenck AccuRate, Whitewater, WI 800-606-9248 www.accuratefeeders.com Smart Weigh-Belt Feeder

Smart Weigh-Belt Feeder

The smart weigh-belt (SWB) feeder offers a continuous in-line auto tare option, which is enabled by a second SFT weighbridge that weighs the empty belt before it receives material. The result is increased accuracy and reduced downtime, even when sticky materials are fed. The feeder is available in two sizes, 300 and 600 mm, based on the width of the belt. Either open-frame or enclosed-frame models are offered. The larger model can handle feed rates of up to 88,000 lb/hr. The stainless-steel weigh-belt feeder is easy to clean.

K-Tron, Pitman, NJ 856-589-0500 www.ktron.com

Vibratory-Tray Feeder for Pellets

Vibratory-Tray Feeder for Pellets

One of the more difficult feeding applications in the plastics industry is the precision feeding of color micropellets at low rates (0.5 lb/hr and less). Micropellets are also often fed in conjunction with a main ingredient pellet. Arbo has created the “V” profile vibratory tray feeder, which controls rate as a slave from a U/MMI controller that runs the main pellet feeder. The system is stable in most environmental conditions and includes two feeders and a loss-in-weight controller.

Arbo Engineering Inc., Toronto, ON, Canada 800-689-2726 www.arbo-feeders.com

You May Also Like