Alumina Powder Silo Retrofit Improves Product Quality

July 28, 2014

The Need

Alumina is a fine powder that is used in the manufacture of aluminum, abrasives, refractory material, and various household products. Large users of alumina often arrange to have it shipped to their plants in 100-ton capacity railcars. The quality and consistency of the alumina, which can vary within each railcar, can affect the manufacturing process. Some processes can detect and compensate for gradual changes without any significant loss of product quality. However, rapid changes may result in a significant loss of finished product because of unacceptable variations.

At a plant operated by one of Jenike & Johanson’s clients, a pneumatic line conveys alumina from railcars to a 12-ft-diam storage bin. This bin was originally designed for mass flow, but the resulting first-in/first-out flow pattern caused variations among railcars to be passed on to the process. The client wanted to blend the alumina in order to smooth out these variations. The logical place to do this was in this bin.

The Solution

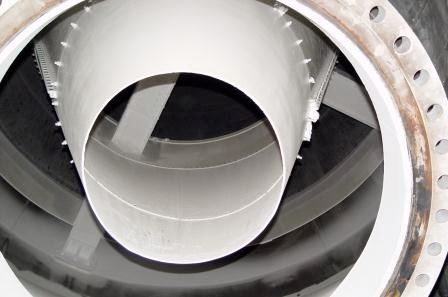

Jenike & Johanson engineers recommended modifying the bin to incorporate a Binsert blender. A scale model of the blender was built and tested. The results caused the alumina to be blended, which reduces the process variation.

Structural calculations were performed and the necessary modifications were made to incorporate a Binsert blender in the conical hopper section. Next, fabrication of the new hoppers and supports were arranged. Engineers then made frequent visits to the fabricator’s shop to ensure quality control.

The Result

This Binsert system has been in operation for several years, providing continuous blending of the alumina. As a result, the rejection rate due to variation in finished products has improved significantly. This dramatic improvement was achieved at a cost of only the Binsert system, which was retrofitted to the existing bin. There were no additional operating costs.

For related articles, news, and equipment reviews, visit our Mixers & Blenders Equipment Zone

You May Also Like