Dust Hazard Assessment: Overview and Common Issues

January 22, 2018

The U.S. Occupational Safety and Health Administration (OSHA) increased the focus on combustible dust hazards and issued the Combustible Dust National Emphasis Program (NEP) in 2008 as a result of the number of catastrophic fires and explosions caused by combustible dust over the last two decades. The NEP describes OSHA’s policies and procedures regarding inspection of facilities that handle combustible dust, as well as their expectations regarding owner/operator compliance with U.S. safety standards (e.g., NFPA). OSHA determined that that many facilities handling combustible dusts were unaware of the associated hazards, or were simply confused by the requirements of the existing commodity-specific standards; e.g., NFPA 61 (1), 484 (2), 654 (3), 664 (4), and/or 655 (5). The NFPA therefore developed and issued NFPA 652 (6; Standard on the Fundamentals of Combustible Dust), which is a governing umbrella standard that addresses fire and explosion hazards associated with combustible dust of all types across all industries, in order to promote further awareness and reduce confusion.

A main focal point of NFPA 652 is the requirement for facilities processing or handling particulate solids to perform a dust hazard assessment (DHA). While a number of the commodity-specific NFPA standards have required a process hazard analysis (PHA) for over a decade, NFPA 652 went a step further by making this requirement retroactive to existing installations and establishing a deadline to have a DHA in place. A DHA is now required for new and existing installations, as well as for upgrades to existing installations. The standard, which came into effect on September 7, 2015, allows affected facilities three years to complete a DHA. To put the importance of a DHA in perspective with regards to regulatory compliance, many OSHA citations regarding combustible dust hazards list the lack of a hazard analysis at the top of the citation. (7)

There are many approaches to conducting a DHA, and the Annex of NFPA 652 provides one example. The recently published CCPS “Guidelines for Combustible Dust Hazard Analysis” (8) provides perhaps the most current and comprehensive overview of the different DHA approaches available to a facility.

Click here for information about the upcoming International Powder & Bulk Solids Conference/Exhibition

This article discusses the most common issues identified during a large number of DHAs performed by the authors over the last several years. Particular focus is given to dust collection systems and associated equipment since such systems are typically present at most particulate solid handling facilities.

1. Lack of Defined Inspection and Cleaning Plan to Meet NFPA Housekeeping Requirements

Dust explosions may be classified as either primary or secondary in nature. Primary dust explosions typically occur within individual pieces of equipment inside process plants or similar enclosures (baghouse, cyclone, grinder, etc.), and are generally controlled by pressure relief venting through purpose-built ducting to atmosphere. Secondary dust explosions are the result of dust accumulations (outside of equipment) within the facility, which are disturbed, suspended, and ignited by the primary explosion, resulting in a more dangerous uncontrolled explosion inside the workplace. Loss history shows that the majority of injuries and fatalities from dust explosions are the result of secondary dust explosions.

Control of fugitive dust emissions and housekeeping outside of equipment are therefore a focus of all combustible dust-related standards and are the key to reducing the potential for a catastrophic event. For example, NFPA 654 (the general commodity-specific standard) provides four separate methods to define a hazardous area. Of the four methods, by far the most convenient to implement is the accumulation layer thickness criterion. NFPA 654 defines a hazardous location as an area where the accumulation of combustible dust exceeds 1/32-in., based on a bulk density of 75 lb/cu ft, with a correction factor to allow for increased accumulation of lower bulk density materials. A hazardous location is deemed to exist if: 1) the total area of dust accumulations exceeding the layer depth criterion is greater than 5% of the enclosure footprint area; or 2) if the area of any single dust accumulation exceeding the layer depth criterion is greater than 1000 sq ft.

NFPA 652 (the umbrella standard) requires that a facility manage dust accumulations to meet the criteria of the relevant commodity-specific standard (e.g. NFPA 654 per above). Surprisingly, very few facilities actually create an auditable system of inspection and cleaning to meet this requirement. Some facilities periodically inspect (e.g. quarterly) and react accordingly, although local accumulations may already have significantly exceeded the identified threshold thickness within this timeframe. Other facilities simply clean on a defined frequency (e.g. annually), regardless of the amount of dust accumulated within this timeframe. Regrettably, some facilities neither inspect for nor clean accumulated dust on any defined schedule.

Although the NFPA standards do not define an approach to achieve compliance, it is BakerRisk’s opinion that the most effective method is to segment the process areas into zones that can be easily inspected by a workgroup or operator, ensuring that there are no gaps between zones. An initial inspection frequency should be established (e.g., every two weeks) and the zone (including elevated surfaces) cleaned as needed when the threshold thickness is approached. For zones that generate dust accumulations at a steady rate, the inspection frequency can be adjusted after a number of inspections have established the accumulation rate. The keys to success are to maintain external dust accumulation levels below threshold levels, develop a reasonable inspection frequency, document the inspections and cleanings, and make the process work intuitively without creating an undue burden. An additional benefit to this zoned approach is that the responsible workgroup will likely begin to identify key equipment that is contributing to fugitive dust emissions, and will seek methods to eliminate the source of the emission (i.e. so as to allow a decrease in the required inspection and cleaning frequencies).

2. Lack of Dust Explosibility Data

It should be clearly recognized that most materials that can combust (i.e. burn) will present a combustible dust fire and explosion hazard if dust is created from processing such materials. That is, dusts generated from combustible material should be assumed to pose a combustible dust fire and explosion hazard unless proven otherwise. However, beyond identifying that a combustible dust hazard exists, facilities often don’t have sufficient information on the combustibility characteristics of their dusts. Performing a simple “Go/No-go” test is fundamental to confirming that a hazard exists. Once the determination is made that the dust is combustible, then additional explosivity parameters may be useful in order to quantify the hazard and develop effective mitigation options. For example, knowledge of the minimum explosible concentration (MEC) may be necessary in order to determine if the process is capable of generating sufficient quantities of airborne dust to present an explosion hazard. Likewise, knowledge of the minimum ignition energy (MIE) is essential when determining the potential for static ignition hazards, which may require operators to be bonded/grounded when performing certain operations.

3. Lack of Rated Deflagration Isolation Device

NFPA standards state that where an internal explosion hazard exists, isolation devices shall be provided to prevent deflagration propagation between connected equipment. Without isolation, an explosion initiated in one piece of equipment could propagate to connected equipment. In addition to allowing the explosion to propagate, this also results in pressure-piling in the downstream equipment which can significantly increase the explosion pressures in the downstream equipment. The connected equipment could therefore fail even if it was protected with a suitable explosion protection system (e.g. explosion vent). An additional concern without proper isolation is exposing personnel working near dust collection duct pick-up points or hoods (e.g. bagging and hand-dumping operations) to the flame propagating through the connecting duct.

There are many varieties and manufacturers of deflagration isolation devices, often sold as “flame-front diverters,” “fast-acting check valves,” “backblast dampers,” or “backdraft valves.” Many observed installations would not function as intended due to either a poor valve mating surface (i.e. would not prevent flame propagation) or a weak housing that would not withstand the deflagration overpressure generated in the connected equipment. The EN 16447 ATEX standard is the only international testing protocol that evaluates these devices under actual blast conditions to ensure they will function as intended over the relevant explosibility parameter range. When selecting a deflagration device, always ensure the device has the ATEX certification and that the device is rated for the explosibility characteristics (e.g. Kst, Pmax) of the dust being handled. NFPA 69 (9) provides guidance for implementation and other considerations relative to isolation devices.

4. Lack of Restricted Access Zones around Equipment Equipped with Deflagration Vents

Restricted occupancy zones must be established around deflagration vents to reduce the likelihood that personnel are present in the vicinity if a deflagration were to occur in the vented equipment. A number of incidents have resulted in injury to personnel located in close proximity to explosion vents due to exposure to the flame and burning debris from the vented deflagration. Equipment controls and E-stops should be located outside of these zones. NFPA 68 (10) provides guidance on fireball distances from vented enclosures that can be used as a basis for establishing restricted access zones; of course, locations right at the edge of the fireball are not necessarily safe due to the high thermal flux, and hence an additional safety distance should be considered. Restricted zone warning signs and barriers should be established to prevent unauthorized personnel access. Permits should be used to evaluate potential hazards encountered by personnel working within the restricted zone, specify appropriate PPE (e.g. FRC), and limit the time to which personnel are exposed to this hazard.

5. Lack of Design Basis Information to Support Explosion Protection Design

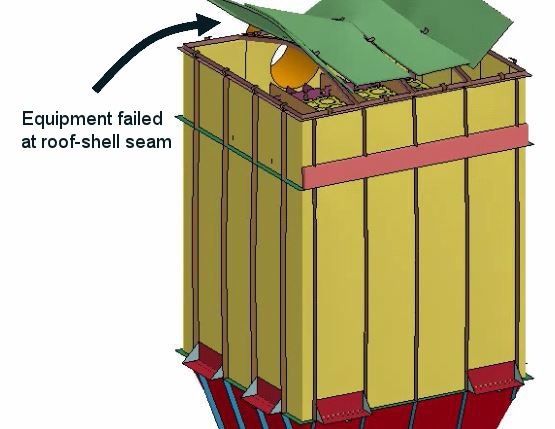

When designing and implementing explosion protection systems (e.g. venting, suppression, isolation), it is imperative that the strength of the protected equipment (e.g. dust collector) is known. For example, the maximum explosion pressure in equipment fitted with explosion vents can significantly exceed the pressure at which the vents open, and the equipment may fail catastrophically if not designed to withstand the maximum pressure. Similarly, if chemical suppression is implemented, the activated suppression system pressurizes the equipment as it injects the suppressant, and hence the equipment will fail if not designed appropriately. In one instance, BakerRisk assessed the capacity a rectangular baghouse with an explosion suppression system and determined that the baghouse would fail at the roof-to-shell seam without additional structural reinforcement, as illustrated in Figure 1; activation of the suppression system, even inadvertently, posed a significant hazard to the operators.

6. Lack of Design Basis System Flow Velocities

NFPA standards prescribe minimum flow velocities through dust collection systems to prevent dust from falling out of suspension and accumulating inside the duct. Dust accumulations can lead to a hidden fuel source that may be ignited by a spark drawn into the system. Duct fires can present a challenge to extinguish and often can damage equipment beyond repair. In some cases, the burning material can be pulled into the dust collection system and initiate a deflagration. Maintaining a minimum flow velocity of 4000 fpm is recommended by NFPA standards to prevent fallout of dust in dust collection ductwork; the actual required velocity is a function of the dust properties. In some cases, facilities have created “peep-holes” in the ductwork into which a flow meter can be periodically introduced to monitor the flow velocity and validate system integrity. Intelligent dust collection systems are also now available that include in-line flow velocity sensors that control the fan speed to maintain the minimum designated velocity, and can balance the system when sections are taken out of service.

7. Lack of Duct Inspection Hatches

The placement of inspection hatches along the dust collection system duct allows for periodic inspection for dust accumulations, although such hatches are not explicitly required by the NFPA standards. BakerRisk recommends that the inspection hatches be located approximately every 20 duct diameters along the main duct. This criterion may be different for individual small diameter trunks sprouting from the main duct. Regardless of specific inspection hatch spacing, the intent is that all sections of the ductwork can be inspected and cleaned sufficiently through the hatches.

8. Spark Suppression System Nozzles Located Too Far from Spark Source

Dust collection ductwork connected to high frequency spark generating equipment (e.g. sander, grinder, hog, etc.) should be equipped with a spark suppression system in order to minimize or eliminate sparks entering the dust collector, which could trigger a collector fire or deflagration. The spark suppression system typically incorporates a sensor (i.e. IR, rate of pressure rise) that detects the spark, along with spray nozzles located downstream at a distance determined by flow velocity. The separation distance between the detector and suppressors is critical; too close and the spark may get beyond the spray before it is activated, too far and the spray may halt before spark arrives. The location of the spark suppression system is also critical. FM Global Loss Prevention Data Sheet 7-76 (11) recommends that the system be located as close to the final piece of spark generating equipment as possible. Otherwise, if dust has accumulated in the duct between the spark generating equipment and spark suppression system, such accumulations may be ignited. Of course, spark suppression systems only reduce the likelihood of ignition, and generally some additional explosion protection is required.

It is also noted that NFPA standards require that horizontal ductwork be capable of supporting the weight of the system plus the weight of the duct half-filled with water (where sprinkler protection is provided in the duct) or the material being conveyed, whichever has the higher density. BakerRisk is aware of at least one case where a large duct collapsed due to the accumulation of water from fire suppression activities.

Summary

The identified common hazards have all been causal factors in actual combustible dust fire or explosion incidents that resulted in the loss of life or severe injury, in addition to the loss of capital assets and business interruption. Performing a robust DHA should identify such hazards and, using the guidance provided in relevant NFPA standards, identify prevention and mitigation strategies that can be implemented to manage the risk associated with combustible dust fire and explosion hazards.

Phil Parsons is a senior consultant at BakerRisk. BakerRisk provides cost-effective solutions to manage risk exposure from fire and explosion hazards. For more information, visit www.bakerrisk.com.

1 NFPA 61 (2017 Edition) Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities.

2 NFPA 484 (2015 Edition) Standard for Combustible Metals.

3 NFPA 654 (2017 Edition) Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids.

4 NFPA 664 (2017 Edition) Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities.

5 NFPA 655 (2017 Edition) Standard for the Prevention of Sulfur Fires and Explosions.

6 NFPA 652 (2016 Edition) Standard on the Fundamentals of Combustible Dust.

7 U.S. Department of Labor Citation and Notification of Penalty, Inspection Number: 1236533, Issued 11/17/2017.

8 Center for Chemical Process Safety (2017) Guidelines for Combustible Dust Hazard Analysis, ISBN 978-1-119-01016-6, CCPS, New York, NY (Dave Kirby and Phil Parsons of BakerRisk both worked on this guideline).

9 NFPA 69 (2014 Edition) Standard on Explosion Prevention Systems.

10 NFPA 68 (2018 Edition) Standard on Explosion Protection by Deflagration Venting.

11 FM Global Property Loss Prevention and Data Sheets 7-76, May 2008, Interim Revision April 2017

You May Also Like