Comprehensive Combustible Dust Explosion Protection

September 25, 2019

Comprehensive combustible dust explosion protection does not necessarily have to be expensive or complicated. An innovative technology makes it possible to divert the shock wave and flames of an explosion in a controlled manner. The result: The required safety area is reduced, so valuable usable area is increased, and personnel/equipment are protected from the explosion’s effects.

Combustible dust explosions occur within a few milliseconds, yet leave behind considerable damage. Different approaches to protecting against the ravages of the explosion are regularly used to limit this damage.

Explosion panels are often used in facilities where release of the explosion to the surrounding external area is possible. Explosion panels, which relieve the explosions by “bursting” at a predetermined pressure point, are economical and relatively easy to manage. However, this type of traditional explosion pressure relief presents a big problem for many facility operators – extensive safety zones must be set up around the relief area to protect people, equipment and the surrounding areas. These zones become unusable space.

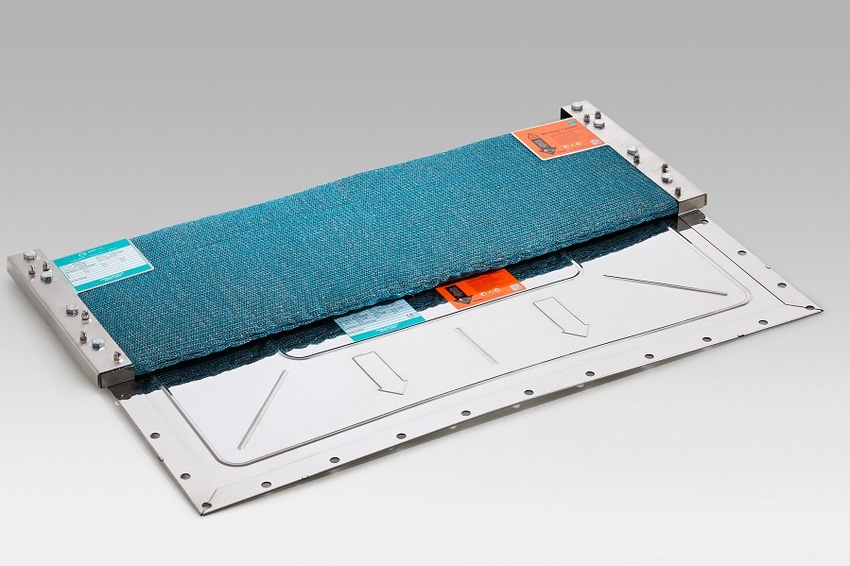

The REMBE Targo-Vent is an opening angle limiter, developed for use with REMBE explosion panels, which guides the pressure relief specifically into areas in which there is no danger to the adjoining infrastructure. Targo-Vent absorbs the enormous repulsive forces of explosion energy and guides the flames and shock wave in the desired direction.

Depending on the application/equipment, the flames and shock wave are diverted at a defined angle of approximately 30°-45° upwards or to the side so facility operators can minimize the safety areas around the vent opening. The usable area is increased.

A further advantage of Targo-Vent is that the top module is made in standard explosion panels sizes, so that it may be retrofit on existing explosion panels without a problem. Retrofits or building additions are protected by Targo-Vent without the need to significantly alter the explosion protection plan of the existing facility.

Targo-Vent is attached directly to the explosion panels—an additional space-saver. There is no need for expensive baseplates or reinforcement. The system is made of maintenance-free stainless steel materials and, in combination with explosion panels, is type-tested in accordance with the ATEX Directive 94/9/EC (ATEX 114), authorized in accordance with (FSA 13 ATEX 1637) and fully conforms to NFPA Standards.

REMBE Inc., Charlotte, NC 704-716-7022 www.rembe.us

More articles that may interest you:

What You Need to Know About the New Edition of NFPA 652

Extracting Combustible Dusts at the Source

How to Use Dust Explosion Test Data to Ensure Facility Safety

Explosion Containment: A Comparison

You May Also Like