Weighing 1861

July 1, 2011

Industrial Scale

Industrial Scale

The completely stainless-steel Signum Supreme is ideal for pharmaceutical applications. The large loading pan allows for the weighing of large quantities of powder while still providing precise measurements, eliminating steps, and cutting down on valuable process time. The dampening system ensures accuracy even in ventilation or vibration-filled environments, and the IP65 wash-down protection makes it clean-room friendly. A variety of communication options, including RS232, Ethernet, and Profibus DP, make it easily integrated into an already existing process and ideal for a dispensing room where a combination of scales are needed. Sartorius Group North America, Bohemia, NY 631-870-8515 www.sartorius-mechatronics.com

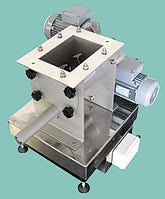

Loss-in-Weight Bulk Bag Discharging System

Loss-in-Weight Bulk Bag Discharging System

The V-Knife Material Master loss-in-weight bulk bag discharging system provides clean, efficient discharge of sealed bottom bulk bags into your process. The system includes a 304 stainless steel discharge hopper with static bag piercing knife, a dust collection system (not pictured) with custom intake plenums, and a loss-in-weight scale system. A variable speed stainless steel screw feeder meters non-free flowing powders into an existing process. Material Transfer & Storage Inc., Allegan, MI 800-836-7068 www.materialtransfer.com

High-Speed Net-Weigh Scale

High-Speed Net-Weigh Scale

The RT 7000 is a net-weigh bagging machine with exact weighments, high production capacity, and operator features in one package. A gravity-fed, primary fill cycle is complimented by a vibratory-fed, secondary cycle to provide the fastest possible rates and the highest accuracy when packaging free-flowing products like grains, pet foods, or granular products. Features include: weights from 15 to 110 lb; automatic calibration; electronically-controlled, adjustable flow gates; infinite vibrator trim fill; simplex or duplex configuration. Taylor Products, Parsons, KS 888-882-9567 www.taylorproducts.com

Weighing/Flow Monitoring

Weighing/Flow Monitoring

Compu-Watt provides continuous weighing/flow monitoring for bucket elevators and conveyors. Weighing applications include railcar/truck/barge loadout and inventory transfer. Flow monitoring applications include flow rate control and proportioning of additives. There is no maintenance, no moving parts, and no contact with the process flow. Inexpensive electrical installation/calibration can be completed in less than one day. Features include programmable overload alarms and multiple weight setpoints. The system can operate stand-alone with a printer and remote displays. It can also interface to a PLC, DCS, or PC. Interface capabilities include RS232, RS485, Modbus, DeviceNet, Ethernet, and 4-20 ma. Compu-Watt, Bragg Creek, AL, Canada 403-949-2418 www.compuwatt.com

Loss-in Weight Feeding System

Loss-in Weight Feeding System

This loss-in weight feeding system is functional, flexible, and easy to use. These loss-in-weigh feeders include a micro-batch feeder with a food-grade body manufactured from stainless steel and SINT engineering polymer, a stainless steel feeder pipe and drive guard, and a platform scale on a microprocessor-controlled load cell. When feeding and metering ingredients in small quantities, the MBF-BE system is able to assess any variation in weight in time adjusting the feed rate by varying the speed of both discharging and feeding device. The MBF-BE has been designed to weigh and control the output of various products for different sectors such as plastics processing, flour milling, chemicals, ceramics, animal feed, and foods. WAMGROUP S.p.A., Cavezzo (MO), Italy +39 0535 618 111 www.wamgroup.com

H igh-Speed Net Weigher

igh-Speed Net Weigher

The BEST Model NW-50 food-grade net-carton-filling system feeds 20-30 lb of snack food chips to 16x20 in. cartons at four cartons per minute with an accuracy of ±0.1 lb. Cartons are indexed into position, filled, vibrated, and moved out on a powered-roller conveyor. The filling machines feature rugged, long-lasting components that require minimum maintenance. Metso Minerals Industries Inc., Brunswick, OH 800-827-9237 www.bestvibes.com

T ablet Scales

ablet Scales

The Tablet Scale series of low-profile, multi-purpose scales offers an easy-to-use, low-profile solution for basic weighing applications from bulk powder weighing to chemical mixing. Made of highly scratch-resistant security glass, the unit is lightweight, portable, and easy to clean. The security glass construction helps to protect the display from shocks, spills, and chemical stains. The Auto Hold function, that retains the displayed weight after the item is removed, allows for the weighing of oversized items with ease. Three models are currently offered, with capacities ranging from 50-200 lb, each with 2500 divisions. The scale comes in three sizes from 12x14 to 20x24 in. Intelligent Weighing Technology Inc., Ventura, CA 805-642-3034 www.intelligentwt.com

M odular Weighing System

odular Weighing System

The Accu-Portion modular weighing system maintains accuracy to 1/10 of one percent regardless of supply bin capacity (standard from 0.5 to 100 cu ft) or the quantity of automated ingredients. Modules are capable of feeding and weighing 1 to 12 ingredients, can be combined to provide 32 or more materials/ingredients within a system, and can process multiple scales simultaneously, maximizing production speed. Modules are available in multiple supply bin configurations and scale hopper designs, eliminating product cross-contamination. These modular designs allow for system expansion or modification. PC/PLCs provide real-time batching data such as weights, batching status, alarm conditions, and batch history. Prater-Sterling, Bolingbrook, IL 630-759-9595 www.prater-sterling.com

Plant-Wide Weigh Batching System

Plant-Wide Weigh Batching System

This automated plant-wide weigh batching system simultaneously weighs up to seven major ingredients received in bulk bags and unlimited minor ingredients received in 50-lb sacks, pails, or boxes, and conveys weighed batches to a downstream blender that feeds a bulk bag filler and a paper sack filling machine. System components include: five loss-of-weight Bulk-Out bulk bag dischargers with large surge hoppers and rotary airlock valves; two loss-of-weight Bulk-Out bulk bag dischargers with small surge hoppers and flexible screw conveyors; two loss-of-weight bag dump stations with flexible screw conveyors; a check-weighing hopper; a Twin-Centerpost bulk bag filler; a Pneumati-con dilute-phase pneumatic conveying system including blower, filter receiver and conveying lines; and a programmable controls package. Flexicon Corp., Bethlehem, PA 888-353-9426 www.flexicon.com

H igh-Resolution Weigh Modules

igh-Resolution Weigh Modules

Versatile, high-resolution WMS weigh modules can easily be integrated into automated processes. They complement all systems, machines, and instruments, and meet demanding standards and quality requirements. Their compact design has a wide weighing range with intelligent mechanical and electrical interfaces. The robust, FDA-compliant stainless steel design features overload stops and a long service life. With up to 92 updates per second and up to 4 million points of resolution, users are able to track and control dosing processes in real time. WMS weigh modules are controlled directly using a PC via RS232 or RS 422, and feature a range of weigh platforms for specific designs, allowing users to weigh on top of modules or under the module. A digital I/O is built in and communicates with one of many communication modules. Mettler-Toledo Inc., Columbus, OH 614-438-4511 www.mt.com/na

Heavy-Duty Weigh Feeders

Heavy-Duty Weigh Feeders

The DMO weigh feeder is used for weighing and feeding up to 500 tn/hr with minimal maintenance and care for heavy-duty industrial applications. The drive system with reducer and motor is directly mounted on the head pulley shaft. This provides for rugged, reliable, and safe operation while the need for alignments and maintenance is eliminated. At the heart of the DMO is a direct multi-cell weighing system that does not use levers or counterbalance weights. This eliminates any chance of error during the weighing process. The DMO comes in standard belt widths of 24 to 54 in. with feed rate accuracies of ± ½% over a 10:1 range. These rates are achievable in a range of material particle sizes up to 4-in. lumps. Schenck AccuRate, Whitewater, WI 800-558-0184 www.accuratefeeders.com

Digital Load Cells

Digital Load Cells

Smart Force Transducer digital load cells incorporate exclusive filtering algorithms that continuously identify and extract spurious weight readings from the weight measurement, even in severe process environments. Precise feeding, batching, and metering of bulk solids begins with precision weighing. Achieving high gravimetric feeding performance in the process line requires discriminating between material weight data and the contaminating effects of forces induced from ambient vibration and shock. K-Tron America, Pitman, NJ 856-256-3265 www.ktron.com/weighing

Continuous Weigh Feeders

Continuous Weigh Feeders

Better-Weigh continuous feeders are used for gravimetric feeding of dry bulk materials where it is necessary to determine actual feed rates on a loss-of-weight basis. Available in seven models with feed rates from 1 to 550 cu ft/hr (larger sizes available), these feeders are designed to provide feeding in either batch or continuous mode depending upon the arrangement of the feeder’s control electronics. In batch mode, the batch controller is used to control the fast (bulk) and slow (dribble) speeds of the feeder. Accuracies of ±0.5% can be easily achieved in 2-lb or less batches, and ±0.25% with 3-lb or greater batches with time spans of 30 to 90 seconds. In continuous mode, the feeder’s electronic controller is used to constantly monitor loss of weight of material per time in order to maintain a continuous loss of weight with an accuracy of ±0.25% to 0.50%. Standard features include a platform or lever balance scale, sealed tactile keyboard, 7-digit numerical keyboard, automatic manual batching, and 2- or 5-cu-ft hopper. Sanitary construction is also available. Metalfab Inc., Vernon, NJ 800-764-2999 www.metalfabinc.com

Bulk Bag Discharger for Weighing & Batching

Bulk Bag Discharger for Weighing & Batching

This loss-in-weight bulk bag discharger meters bulk ingredients and/or minor additives for complete control of product dispensed from the bag. The Type 3 bulk bag discharger accurately dispenses bulk ingredients and/or minor additives from 20- to 3500-lb batches by using electronic load cells directly below the top bag holding frame. This assures that the bag and load cells are safely off the floor out of the way of facility hazards such as forklifts. As an option, an integral transfer conveyor, such as a flexible screw conveyor, can be suspended from the holding frame for a totally self-contained discharge and loss-in-weight dispensing system. Spiroflow Systems Inc., Monroe, NC 704-291-9595 www.spiroflowsystems.com

H igh-Accuracy Weighing and Batching

igh-Accuracy Weighing and Batching

The GYRO bin activating feeder produces 360 degrees of pure gyratory motion to positively and more reliably feed and/or discharge granular materials from bins, storage silos, and hoppers at any desired feed rate. At the heart of the bin activating feeder is the drive that produces 360 degrees of radial force, creating a uniform circular motion on all parts of the feeder. It is this annular radial vibratory motion which imparts the ultimate force, assuring a constant and reliable material flow. This also minimizes any material stratification in the storage silo or bin and develops a predictable and positive flow of material upon demand. The GYRO bin activating feeder can operate either continuously or as a start and stop operation as might be required for more sophisticated process applications. Also available is an optional variable speed drive that provides a variable material discharge rate with up to a 400 to 1 turndown ratio for batch weighing operations. Dynamic Air Inc., St. Paul, MN 651-484-2900 www.dynamicair.com

T urn-Key Weighing System

urn-Key Weighing System

The pre-engineered and pre-programmed 920i FlexWeigh system is a turn-key answer to many of manufacturing’s most commonly used weighing processes, providing a clearly defined, immediate solution to almost any weighing operation. There is no need for lengthy quoting or design obstacles. Each 920i FlexWeigh control panel is a standard design in its own right, factory tested and programmed for the task at hand, yet customizable. Stainless steel NEMA-4X enclosures and rugged, customizable operation switches guarantee industrial strength and dependability. Once you’ve selected the right model for the job, the 920i FlexWeigh system is shipped complete and ready to transition almost any measurement task into a fully automated weighing process. Rice Lake Weighing Systems, Rice Lake, WI 800-472-6703 www.ricelake.com

Net Weigh Scale/Screw Feeder

Net Weigh Scale/Screw Feeder

The E-55 net weigh scale/screw feeder is designed to handle non-free-flowing, powdery, or fluidized products. It comprises one main screw for the bulk filling cycle and one smaller screw for the dribble filling cycle. Each screw is directly driven by its own motor in order to minimize moving parts and thus reduce maintenance and wear. Designed for easy cleaning, the screws are contained in a totally enclosed housing which ensures no dust emission. Its sanitary design and proven high accuracy will ensure optimum operations at up to 12 BPM. High hygienic standards are achieved; all contact parts are in SS304. A duplex configuration is available for high speed. Premier Tech Chronos, Rivière-du-Loup, QC, Canada 418-868-8324 www.ptchronos.com

Polycarbonate Enclosure Weight Indicator

Polycarbonate Enclosure Weight Indicator

The rugged polycarbonate enclosure makes the new 212G STORM series weight indicators ideal for a wide range of weighing applications, whether it’s a simple bench scale, a heavy-duty floor scale, or even a tank/hopper load cell application. The NTEP legal-for-trade indicators are ideal for every weighing application from basic weighing to complex operations using the full keypad (selectable key lockout enables unused keys to be disabled). All setup may be accomplished through the front panel. Cardinal Scale Mfg. Co., Webb City, MO 800-441-4237 www.CardinalScale.com

You May Also Like