Technology Review

October 11, 2011

Modular Conveyor Flat Guards

Modular Conveyor Flat Guards

This line of conveyor safety equipment is designed to ensure workers are protected from hazardous moving machine parts and pinch points within the conveyor system. The Safe-Guard line of products is also versatile and constructed from powder-coated steel. The MSHA- and OSHA-accepted flat return conveyor guard’s pre-engineered panels install easily and prevent workers from unauthorized access to areas within the conveyor system. The quick and modular set up allows for drop-in installation anywhere on the conveyor system. Shipped with complete mounting kits for quick assembly, the drop pin and wedge clamps hold the guard securely. ASGCO Manufacturing Inc., Allentown, PA 800-344-4000 www.asgco.com

Vibrators and Drives for Hoppers and Bins

Vibrators and Drives for Hoppers and Bins

BEST heavy-duty air-powered-piston and rotary-electric vibrators and drives are designed for bins, hoppers, chutes, screeners, vibratory feeders, conveyors, tables, and other vibratory applications. All provide continuous maximum-force operation—from 30 to more than 40,000 lb. These dust-tight, splash-proof motors provide field performance in harsh environments including dirt, rain, and snow. Heavy-duty construction —including ductile-iron castings, steel end covers, and high-alloy fasteners — assures long life. Metso Minerals Industries Inc., Brunswick, OH 800-827-9237 www.bestvibes.com

Oval Replacement Cartridge Filters

Oval Replacement Cartridge Filters

These oval replacement cartridge filters include Protura Nanofiber Filtration Technology that is scientifically proven to achieve higher efficiency, cleaner air, lower pressure drop, longer filter life, and greater energy savings than any other media used in cartridge filters. Rated at MERV 15, the filters are nearly 50% more efficient on 0.3 to 1.0 micron dust particles than a MERV 13 nanofiber filter, achieving even higher efficiencies when compared to commodity filters. Users can increase operational savings through lower pressure drop over the life of the filter and less overall system energy cost, as well as reduce filter replacement costs with superior surface-loading technology to enhance dust cake release, leading to extended filter life. United Air Specialists Inc., Cincinnati, OH 800-252-4647 www.uasinc.com

Mercury-Free Tilt Sensor

Mercury-Free Tilt Sensor

Mercury-free tilt sensor is now available for hazardous area applications with approvals for ATEX 20/21/22 and cCSAus for Class I, Division 1 & 2 applications. The sensor incorporates advanced probes and controls that provide enhanced stability, sensitivity, and performance. Specially developed to address environmental concerns and meet government regulations, the unit is easy to install and available with various probe assemblies, making it ideally suited for applications using an array of materials in a wide range of production and process environments in the power, aggregate, paper, coal mining and processing, and mineral mining and processing industries. Thermo Fisher Scientific Inc., Minneapolis, MN 800-445-3503 www.thermo.com

Mixers & Blenders

Mixers & Blenders

This full range of Gardner mixers and blenders features the Easy-Clean cantilever shaft. The cantilever design agitator shaft eliminates one set of bearings and seals at the non-drive end of the shaft. Along with the full diameter hinged and safety interlocked door, this improves access for cleaning and hygiene. The completely contained mixing media provides an ideal environment for dry, semi-dry, or moist powder applications. Mixers and blenders are available in various designs with a choice of plough, paddle, or interrupted spiral agitator. Kemutec, Bristol, PA 215-788-8013 www.kemutecusa.com

Solids/Liquid Injection Manifold

Solids/Liquid Injection Manifold

The Solids/Liquid Injection Manifold (SLIM) is a high-shear mixer system designed to prevent the formation of agglomerates and “fish eyes” in thickened solutions. This novel method of powder induction utilizes a specially engineered rotor/stator assembly that generates a powerful vacuum for drawing solids into the mix chamber. The liquid stream enters the mixer and immediately encounters the powder addition under intense shear conditions. The resulting dispersion is expelled centrifugally through the stator openings at high velocity. Stubborn agglomerates and “fish eyes” are prevented from forming. The sub-surface addition of solids also eliminates the occurrence of floating powders in batch tanks. A “hose & wand” attachment to the powder inlet of the SLIM allows operators to conveniently draw lightweight, free-flowing powders straight from within the bulk container. For faster induction rates, solids are loaded into a hopper located right above the mix chamber. Charles Ross & Son Co., Hauppauge, NY 800-243-7677 www.mixers.com

Filter Media

Filter Media

Shiny nylon and polyester satins provide excellent cake release for problematic sticky or fibrous dust, while high-breathing mono-filaments and rugged coated fabrics are available for filters enduring harsh outdoor conditions. Each system is custom designed to customer needs and based on CFM, dust type, and usage, within space available. American Fabric Filter Co., Wesley Chapel, FL 800-367-3591 www.americanfabricfilter.com

Hydraulic Container Dumper

Hydraulic Container Dumper

This unit accepts containers of bulk solid material and discharges the containers at 57 in. above floor level. It has a 60 x 48 in. loading “skip” with heavy plate steel reinforcements for strength, as well as all tubular frame construction with continuous welds. Equipment includes flattened and expanded metal machine guarding with load side safety sensors. The unit features a safety lock out/tag out system for maintenance or cleaning beneath equipment. Units are custom designed for specific application requirements. Material Transfer & Storage Inc., Allegan, MI 800-836-7068 www.materialtransfer.com

Gravimetric Batch Blender

Gravimetric Batch Blender

The 12 kg model Guardian Series 2 gravimetric batch blender introduces the new see-through mixing chamber door that allows for an unobstructed view of material in the mixing chamber. The design provides precise batch-to-batch dispensing and consistent homogenous blending. Standard features include off-the-shelf controls, color touch-screen, removable cartridge V-gate metering, segmented material hoppers, integral drain chute, and a “No Dead Zone” mixing chamber. The blender may be configured with 4-12 ingredient hoppers, with each hopper capable of running 0-100% of the recipe with dispensing accuracy up to +/-0.02%. Four models include 1.25/2.5, 5, 12, and 18/25 kg, with throughput rates to over 10,000 pph. Process Control Corp., 770-449-8810 Atlanta, GA www.process-control.com

Particle Size and Shape Analyzer

Particle Size and Shape Analyzer

The Haver Tyler CPA 2-1 is a photo-optical particle size and shape analyzer. The unit is ideally designed for laboratory use for measuring dry, free flowing, and non-agglomerating particles. Exclusive Haver software performs a correlation calculation, matching CPA 2-1 raw data to traditional test sieving results. The CPA 2-1 counts and measures, in real time, each individual particle of a representative material sample. The unit conveys dry, free-flowing material samples to fall past a high-resolution camera lens, which takes approximately 20,000 scans per second. This technology provides consistent, repeatable results. The CPA 2-1 user can select from a virtually infinite list of measurement “openings” for custom analysis. ASTM, ISO, and all other international standard sizes are available in addition to specific custom sizes the application may require. W.S. Tyler, Mentor, OH 800-321-6188 www.wstyler.com

Vibratory Conveyor

Vibratory Conveyor

An engineered modification of the Iso-Flo vibratory conveyor, the Iso-Glide achieves a motion that resembles horizontal motion, which maximizes sanitation while offering gentle handling and quiet operation. Iso-Glide can perform a range of product handling and packaging distribution functions, including scale feed applications. It allows processors to experience the continuous self-cleaning benefits of horizontal motion conveying but on an Iso-Flo platform. Product virtually slides along the stainless steel conveyor bed, which prevents the buildup of coatings, oils, and seasonings. By limiting vertical acceleration to almost 1 g, Iso-Glide helps reduce plant-level noise that traditional direct drive or other vibratory conveyors can produce with conveying surface-to-product contact. Key Technology Inc., Walla Walla, WA 509-529-2161 www.key.net

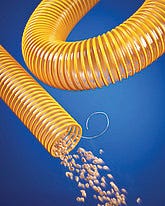

Flexible Pneumatic Conveying Hose

Flexible Pneumatic Conveying Hose

FlexStat 60 heavy-wall static dissipative polyurethane hose is flexible and designed to replace heavy-wall PVC and rubber hose in bulk pneumatic conveying applications. It is made from a specially formulated polyurethane, features .60-in.-thick wall, reinforced with a rigid external ABS helix, and an embedded copper grounding wire. Designed for demanding bulk pneumatic conveying applications, this bendable heavy-wall static dissipative hose has a smooth interior to minimize friction loss. Ideally suited for bulk pneumatic handling from railcars or silos into vessels or tanks, the hose has a clear wall with a yellow helix and comes in 4-, 5-, 6-, and 8-in. I.D. sizes, in 25- and 50-foot lengths. Flexaust, Warsaw, IN 800-343-0428 www.flexaust.com

Planetary Dual Disperser

Planetary Dual Disperser

The Planetary Dual Disperser (PDDM) is ideal for powerful mixing of high viscosity applications requiring ultra-fine dispersion quality. It features four agitators – two planetary stirrers and two high-speed shafts – all rotating on their own axes while orbiting the mix vessel on a common axis. Pictured is a 40-gal model equipped with q built-in vacuum pump assembly for operation up to 29.5 in. Hg. The two saw-tooth blades on each high-speed shaft provide an intensive shearing action, promoting solids dispersion and particle size reduction. The planetary stirrers continually turn over batch material, help feed fresh product to the high-speed blades, and facilitate uniform temperature throughout the mix zone. Sidewall and bottom scrapers can also be installed to further ensure superior heat transfer between the vessel jacket and batch material. Charles Ross & Son Co., Hauppauge, NY 800-243-7677 www.mixers.com

Vibratory Weigh Scale Packers

Vibratory Weigh Scale Packers

GWT grid top, vibratory weigh scale packers equip production and shipping departments with a complete solution for filling, weighing, compacting, and conveying containers of bulk solids with capacities as high as 4000 lb. Durably constructed in mild or stainless steel, these products are an ideal interface to roller conveyors. GWT packers conveniently mount below conveyor rollers allowing bags, drums, trays, or other containers to easily be transported directly onto its grid top deck. With the GWT packer grids designed to raise between conveyor rollers, there is no need for operators to manually move containers. The packer lifts the container to the appropriate height, runs the selected vibration cycle time for fast, effective compaction of material as it is being filled, and weighs the container throughout the entire process. The filled, compacted container is lowered back onto the roller conveyor, enabling it to be moved to the next step as an empty container approaches. Cleveland Vibrator Co., Cleveland, OH 800-221-3298 www.clevelandvibrator.com

Unattended Weighing Systems and Data Management

Unattended Weighing Systems and Data Management

Cardinal provides complete truck scale solutions, including unattended systems for driver operation. The RE series outdoor systems can be configured to meet the customer’s specific operation with a variety of software and hardware features. Driver prompting on the outdoor weight display creates an easy-to-use and efficient management system for your customer’s complete fleet and material management needs. When truck ID security is necessary, Cardinal incorporates proximity badge readers to identify each truck and its materials for shipping and receiving inventories. The proximity badge reader is built right into the RE system enclosure which thermally prints tickets for driver records. Cardinal Scale Mfg. Co., Webb City, MO 800-441-4237 www.CardinalScale.com

You May Also Like