February 11, 2020

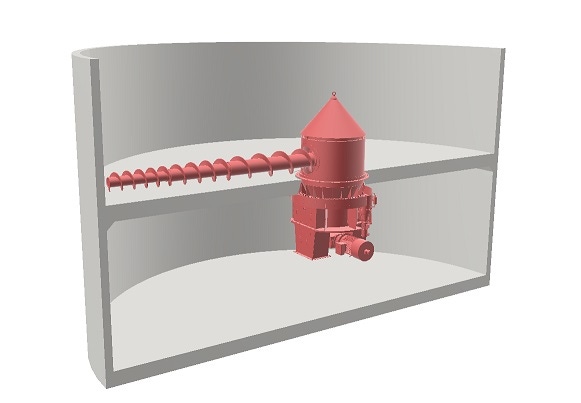

The type RSD rotating screw discharger is a discharge system for dry or damp bulk materials that do not flow easily.

The screw discharger travels over the silo floor by rotating around the vertical axis of the cone and conveys the material into the chute beneath the cone. The screw discharger can be adapted to the individual bulk material by variations in the design of features such as the cladding, the teeth, or the pitch of the screw.

Screw dischargers can be installed in steel or concrete silos. Depending on the material properties and the diameter of the silo, conveying capacities of up to 450 cu m/hr can be achieved. The maximum silo diameter is about 25 m.

AUMUND Fördertechnik GmbH, Rheinberg, Germany, +49-2843-720 www.aumund.com

Click here for information about the upcoming International Powder & Bulk Solids Conference/Exhibition

Here are more articles that may interest you:

Accurate Data Required for Bin Discharger Selection

How to Reduce Safety Risks When Storing and Handling Bulk Solids

Storage Silos 101

Protecting Low-Pressure Storage Tanks in the Food Industry

You May Also Like