- Equipment

- Dust Collection

- Industrial Feeders

- Instrumentation & Control

- Mechanical Conveying

- Mixers & Blenders

Inside the Bulk Solids Innovation Center - Full-Scale Test Lab

July 7, 2015

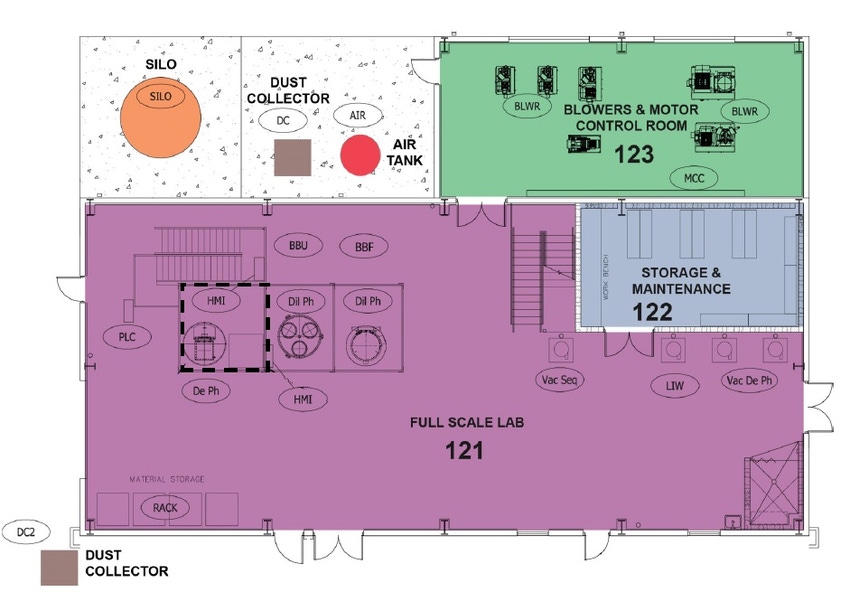

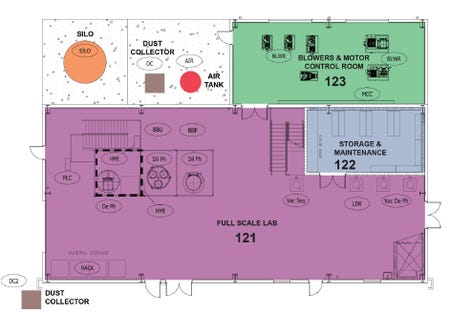

The full-scale test lab at the Kansas State University Bulk Solids Innovation Center is the heart of what the center is intended to provide for students and industry workers. Here students will be able to see the equipment in action and learn what the difference is between dense phase pneumatic conveying and dilute phase conveying, and better understand powder flow problems. Below is a floor map, as well as an image that details some of the more specific equipment that makes up the full-scale test lab.

Room | Description | Supplier | Purpose |

121 | Full Scale Laboratory |

| Equipment and Controls for measurement of actual bulk solids behaviors including storage, conveying, gravity flow, blending, segregation, degradation, dust collection, safety, and air pollution control |

BBU | Bulk Bag Unloader | Holds a 2,000 lb bulk bag of product and discharges it into the process. | |

BBU | Hoist | Kenrich/Harrington | Lifts the bulk bag onto the bulk bag unloader |

BBF | Bulk material filling system for bulk bags and other containers | Ensures reliable, repeatable, highly accurate bulk bag and bulk container filling and weighing; reduces dusting and material loss; provides optimal line speed; improves safety of personnel and product. | |

PLC | Programmable Logic Controller | This is the "brain" of the control system. All devices, motors, and instruments are connected to it. It reads the status of each input and sends an output signal to control each device in the full scale lab. | |

PLC | Control Panels and Programming | Design and programming of the control system. Design and assembly of the control panels. | |

DePh | Dense Phase Conveying | Provides slow motion conveying to prevent damage to fragile products, or reduce wear with abrasive materials. Includes continuous conveying with rotary valve or batch conveying with a pressure vessel. | |

DilPh | Dilute Phase Conveying | Provides industry-proven higher velocity pneumatic conveying, using either pressure or vacuum | |

HMI | Human/ Machine Interface | Touch-screen operator control screen. This is where the operator reads information, starts, stops, and controls all of the systems in the full scale laboratory. | |

HMI | HMI Progamming | Programming of all the controls automation. Design and assembly of the electrical enclosure panels. | |

Vac Seq | Vacuum Sequence Conveying | Provides inexpensive conveying for small and medium rates up to 15,000 lb/hr. | |

Vac DePh | Vacuum Dense Phase Conveying | Provides slow motion conveying under negative pressure. | |

LIW | Loss-in-Weight Feeders | Provides precise weighing and feed control of ingredients into processes. | |

| Steel Structures/Mezzanine Supports/Stairs | Hawk Installation & Coperion K-Tron |

|

RACK | Pallet Rack | Fastenal | Pallet rack to hold pallets of test material. |

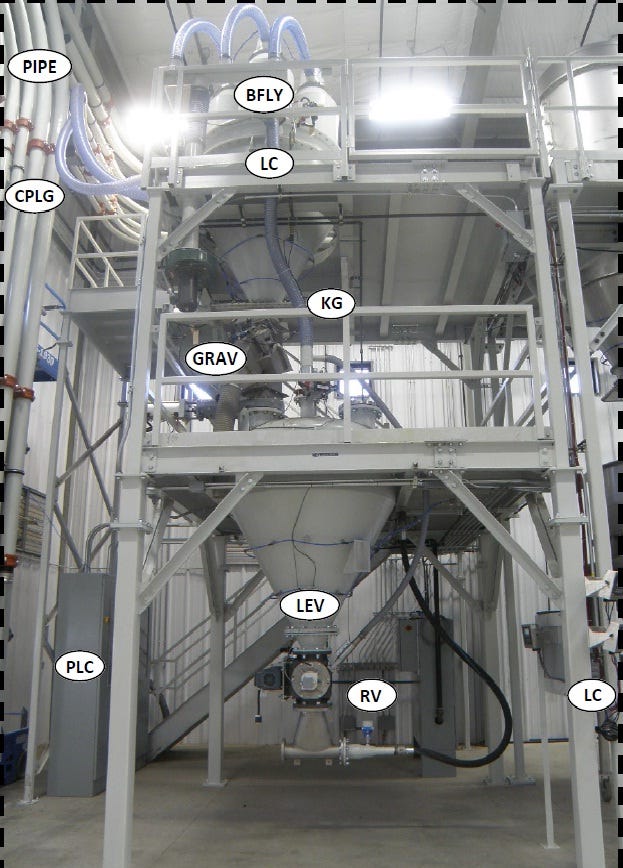

PIPE | Piping Systems | 3, 4, and 6 in. pipe systems, with configurable distances up to 920 ft horizontal length and 65 ft vertical height. | |

BFLY | Butterfly Valves | White Equipment Controls | Uses a rotating disc to open or close the valve, which allows or prevents flow through the valve. |

LC | Load Cells & Weighing Instruments | Hoppers and vessels are mounted on load cells, which send an electronic signal indicating the weight of material in the vessel. A floor scale is used to weigh moveable containers. | |

CPLG | Pipe Couplings | Gruvlock | High pressure, re-usable pipe couplings. |

KG | Knife Gate Valves | Uses a sliding knife plate to open or close the valve, which allows or prevents flow through the valve. | |

GRAV | Diverter Valves for Gravity Flow | Uses a pivoting blade to direct flow to one leg or the other. | |

LEV | Level Controls | Detects high or low level of material in a hopper or silo. | |

RV | Aerolock Rotary Valves | Feeds material into the process or conveying system. | |

RV | Motors | Barr-Thorp Electric /Toshiba | Industrial grade, high-efficiency motors, inverter duty. |

DV | Diverter Valves for Conveying | Uses a slide gate with an orifice to direct flow to one pipe direction or the other. | |

WZK | Diverter Valves for Conveying | Uses a rotating tunnel to direct flow to one pipe direction or the other. |

Images and equipment lists provided by Coperion K-Tron and Kansas State University Salina.

You May Also Like