Editors Choice

July 1, 2011

Rotating Paddle Switches with Universal Voltage Electronics

Rotating Paddle Switches with Universal Voltage Electronics

Rotonivo RN3000, RN6000, and RN4000 level switches can now be used anywhere in the world regardless of the country’s input voltage system, without the need for manual alteration to the paddle switch. The instrument detects the input voltage present and makes the necessary adjustments automatically. Manufacturers and suppliers of storage systems can now order one paddle switch, under one part number, to meet the requirements for all applications in all countries. The RN3000/6000 and RN4000 range of switches now run with an internal heating system. As a result, the paddle switches are suitable for applications in conditions down to -40°C. The range now includes an adjustable time delay system that allows for customization of actuation of the switch. The sealing between the silo and the switch is improved by the addition of a flat, rubber gasket that eliminates leakage and the need for PTFE thread tape.UWT (UK) Ltd, Betzigau, Germany 0845 4810463 www.uwtuk.com

Fluid Bed Drying

Fluid Bed Drying

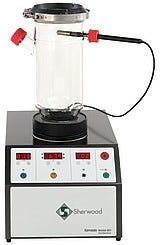

The Model 501 programmable fluid bed dryer provides a lab scale method of rapid moisture reduction/removal at relatively low temperature. Multiple configurations and microprocessor control ensure complete flexibility for a wide range of applications. The fluid bed dryer delivers a high air flow rate, breaking up wet samples and ensuring vigorous mixing so that drying is not only fast but uniform, with no lumps or caking of the particles. Microprocessor control of the air flow, inlet air temperature and drying period, and a temperature/humidity probe within the tub assembly, enable all stages of the drying process to be programmed, monitored, and analyzed. Offering a maximum sample capacity of 5kg, the Model 501 is compatible with both glass and stainless steel drying tubs of various volumes, and with a range of inlet and outlet filters and other accessories. This versatility makes it possible to dry hundreds of different sample types as well as carry out mixing, granulation, and other processes.Sherwood Scientific Ltd., + 44 (0)1223 243444 Cambridge, UK www.sherwood-scientific.com

Redesigned Silo and Bin Cleaning System

Redesigned Silo and Bin Cleaning System

This do-it-yourself silo and bin cleaning system has been completely redesigned and now offers both a new hydraulic cutting head option (JR360H) and the previously available pneumatic cutting head (JR360P). The redesign and new options enhance ease of operation and improve worker safety. Customers now have a choice of a pneumatic cutting head or the hydraulic cutting head. The JR360H system simply requires access to electricity, whereas the JR360P system requires an air compressor or plant air. The hydraulic cutting head provides the operator with greater torque and, due to the availability of a new, higher RPM motor, equivalent operating speed. Customers who prefer Mole•Master’s pneumatic cutting head for their silo and bin cleaning system will need access to an air source. But they still will benefit from enhancements to the overall design and knowing that there is zero chance for contamination of their material since hydraulic fluid is not powering the cutting head.Mole•Master, Marietta, OH 800-322-6653 www.molemaster.com

Laboratory Mixing Granulator

Laboratory Mixing Granulator

The MGTL laboratory model is a powerful mixing granulator for small batches to supplement the proven series. Equipped with a double jacket and interchangeable vessels, it supports the process stages of small-scale mixing, moistening, granulating, and heating/cooling. A three-arm mixing impeller rotates on the floor of the vertical, cylindrical mixing vessel, circulating the mixing product as a vortex. The result: even with product components with heterogeneous properties, this process guarantees extremely short mixing times and excellent homogeneity. A separately driven chopper enables agglomerates to be broken up according to the application, even moistening for wet granulation and – such as in the cosmetics industry – streak-free mixing of dyes. Various easily interchangeable drums make the laboratory mixing granulator ideal for diverse small scale applications.Gebr. Lödige Maschinenbau GmbH, Paderborn, Germany +49-5251-309-371 www.loedige.de

Sanitary Bulk Food Containers

Sanitary Bulk Food Containers

Sanitary Ship Shape bulk forklift containers are rotationally molded in a single piece from 100% USDA/FDA-approved linear low-density polyethylene (LLDPE) to permit contact with food and beverage ingredients and finished products during storage, processing, and transport without concern for contamination and without requiring an internal plastic liner. Developed for material handling and packaging managers, process engineers, and other professionals concerned with food safety and plant cleanliness, the MOD bulk forklift containers replace wooden containers that require plastic liners with a convenient, one-piece, sanitary bulk bin that cannot absorb water, harbor bacteria, or provide a home for pest infestations. The smooth, plastic containers offer superior strength than heavy, wooden containers at lighter tare weights to reduce the load weight during transportation and promote safer, easier lift truck handling. The unitizing, reusable containers also eliminate the need for pallets. The containers are available with capacities ranging from 32 to 44 cu ft on standard footprints with either four-way or two-way lift access to seamlessly integrate into existing warehouse and logistics systems. The rugged containers are available in 16 standard colors and in custom colors in quantity.Meese Orbitron Dunne Co., Ashtabula, OH 800-829-4535 www.ShipShapeContainers.com

You May Also Like