Editor's Choice 1892

August 1, 2011

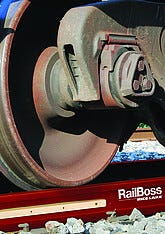

Rail Scale

Rail Scale

Integrated directly within the rail itself, RailBoss requires minimal space and installs quickly, at roughly one-third the cost of conventional railroad scale designs. Scrap yards, agricultural operations, and more can install their own in-house railroad scales for stationary weight verification of rail cars and other non-Legal-for-Trade needs. RailBoss pairs with Rice Lake’s 920i programmable indicator/controller and exclusive RailBoss software to offer scale capacities up to 320,000 lb, available in either eight-section full-draft systems or simpler four-section double-draft models. Rice Lake Weighing Systems, Rice Lake, WI 715-434-5364 www.ricelake.com

Rotary-Style Drawer-in-Housing Magnet

Rotary-Style Drawer-in-Housing Magnet

The RotoDrawer is a rotary-style drawer-in-housing magnet designed to remove ferrous metal from powder and bulk processed products with difficult flow characteristics and a tendency to bridge and choke. This magnetic separator is ideal for products that require a high degree of product purity, but have a higher moisture content or particle size, such as flours, cake mixes, or corn starch, making them difficult to process through stationary tube magnet housings. The RotoDrawer features a motorized, cylindrical configuration of rare earth magnetic tubes that continually rotate through a gravity-fed product stream. The rotational design of the magnet, along with the unique splitter bars, break up any clumps of product and keep the flow moving through the housing while capturing ferrous metal contamination and purifying the product. The RotoDrawer is available in either an EZ-Clean or Self-Cleaning design to simplify the removal of collected metal and prevent any metal wash-off back into the product stream. Standard sizes range from 8x8 in. to 18x18 in. inlets and outlets, with custom designs and sizes available to fit exact application requirements. Industrial Magnetics Inc., Boyne City, MI 800-662-4638 www.magnetics.com

Dual-Outlet De-Duster

Dual-Outlet De-Duster

Traditional DeDuster designs require the product inlet and outlet to be in a straight line. The ability to provide low cost, high-quality packaged granular materials at increasingly high flow rates has proven challenging to the bulk handling industry. The new, patent-pending Dual-Outlet DeDuster can fill two bagging machines simultaneously. This is an economical solution for installing a DeDuster in existing or new packaging facilities. All other features of the DeDuster system technology, including the magnetic field and the Venturi zone, remain unchanged. Low installation height makes retrofitting DeDuster systems into existing facilities possible. The systems are used in the bulk handling industry for cleaning of all kinds of granular products. They reduce the scrap rate and increase profitability by removing unwanted contaminants prior to processing, extrusion, and/or packaging. Pelletron Corp., Lancaster, PA 717-293-4008 www.pelletroncorp.com

Rotary Feeders

Rotary Feeders

Designed specifically for pneumatic conveying of dense materials, such as fine powders used in chemical and pharmaceutical processing, food and bakery processing, plastics, and milling, the Aero-Flow series of rotary feeders provides efficient, air-assisted, material introduction to pneumatic conveying systems. The feeders use a proprietary, dual-induction endplate design to introduce pressurized air from both endplates into the rotor pockets carrying process material. The high bulk density material, when mixed with air, is more effectively released from the rotor pockets, and is more efficiently introduced to the pneumatically conveyed material flow. The Aero-Flow series dual-induction design speeds the material fluidization process, improves material consistency, and optimizes feeder energy consumption when compared to conventional, single-induction feeder designs. Further energy efficiency is provided by an available ACS variable frequency drive to modulate the feeder drive speed and reduce power requirements based on the fluctuating performance needs of the system. ACS Valves, Caledonia, ON, Canada 800-655-3447 www.acsvalves.com

Telephoto Lens for Laser Diffraction Process Systems

Telephoto Lens for Laser Diffraction Process Systems

The introduction of a new telephoto lens for Insitec laser diffraction process systems enables the on-line measurement of larger particles, extending their application in the minerals, powder coatings, and food industries, among others. By combining two different focal length lenses, the telephoto design concentrates an expanded measurement range, with a new upper limit of 2500 µm, into a physically shorter lens, just 160 mm in length. Compatible with all current Malvern process products, the new lens can replace those 300 or 450 mm models currently in use in the field. By increasing the upper sizing limit of Insitec technology from 1000 to 2500 µm, the lens broadens access to reliable continuous laser diffraction particle size measurement, enabling customers to tackle new applications and increase the efficiency of current systems. Malvern Instruments Inc., Westborough, MA 508-768-6400 www.malvern.com

You May Also Like