Vacuum Systems & Cleaning

June 7, 2011

Redesigned Industrial Vacuum Loader

Redesigned Industrial Vacuum Loader

Design improvements of the redesigned Guzzler NX industrial vacuum loader include a more powerful blower and quiet operation. Built for clean-up and recovery of a wide range of materials, including solids and dry bulk powders, the unit provides total operator control over working speed, making it extremely versatile. At the heart of the unit is a powerful Robuschi blower that delivers 5435 (free air) CFM, with vacuum capabilities up to 28 in. of mercury. The larger, injection-cooled blower allows the operator to load more material at a lower engine RPM, conserving fuel and reducing noise levels. These advancements in blower and silencer technology eliminate the need for a sound shroud. Guzzler Manufacturing, Streator, IL 800-627-3171 www.guzzler.com

Explosion-Proof Vacuum

Explosion-Proof Vacuum

The FRV1400 vacuum is certified explosion proof, OSHA and NRTL compliant, and rated for continuous duty. Using a MaxFlo turbine, this compact vacuum operates at just 5 HP and has less than 8 cu ft of internal area, yet provides 300 CFM and enough power to be used as a point-of-source dust collector or central vacuum system. Ideal for grains, sugar, flour, plastics, and other combustible solid or fine dust, the FRV1400 produces more vacuum in a compact compression cast housing compared to stainless steel models. The housing is carbon impregnated, completely anti-static, will never dent, and guaranteed for life. It is also completely portable and can operate hundreds of feet of central vacuum tubing and hoses up to 3 in. in diameter. Ruwac, Holyoke, MA 413-532-4030 www.ruwac.com

Fully-Enclosed Vacuum System

Fully-Enclosed Vacuum System

This vacuum system was developed to suction the ashes of precious metal palladium from oven sheets into transport barrels. The fully-enclosed system features the advanced, pneumatic Multijector vacuum conveyor offering dust-free transfer with a gentle, segregation-free, vacuum-plug-flow system for capacities from 10 to 8000 kg/hr, with transporting distances up to 100 m and up to 50 m high. By converting its transfer process to this vacuum system, the company was able to reduce the costly product loss resulting from the manual dumping of precious metal ash into the barrels and also eliminated the health and safety risks arising from precious metal dust clouds that were being created by manual transfer. Volkmann Inc., Hainesport, NJ 609-265-0101 www.volkmannusa.com

Pulse-Cleaned Industrial Vacuum

Pulse-Cleaned Industrial Vacuum

This pulse-cleaned industrial vacuum reduces clogs to prevent the problems that result from loss of suction during cleaning. The FarrVac is the first such unit to operate without compressed air and may be used for everyday cleanup, as a dedicated dust collector for a single process machine, or as an accessory to an installed dust collector when replacing or emptying dust drawers or drums. Using pulse-cleaning vacuum control technology that works with ambient air to flush filters of dust and debris automatically, the heavy duty FarrVac offers dependable performance and lower initial and operating costs than many similar units requiring compressed air. The unit comes equipped with durable spun bond polyester filters that last up to 10 times longer than conventional filters and capture dust particles to 0.1 micron. Camfil Farr APC, Jonesboro, AR 800-479-6801 www.farrapc.com

Industrial Central Vacuum Systems

Industrial Central Vacuum Systems

These easy-to-use industrial central vacuum systems provide efficient vacuum power for fast clean-up and are designed to run under difficult conditions for long periods of time without plugging. The systems are available with horsepower ratings from 5 to 150 and hoses in 50-ft-plus lengths and 3- to 6-in. diameters that connect to a centrally located material collection hopper. Users benefit from intense vacuum power to clean or remove material or hazardous spills as soon as they happen. These low-energy-consumption units are custom-built to suit customer applications, material type, and facility size, and are adaptable to suit any facility layout for ease of use and efficiency. Airlanco, Falls City, NE 800-500-9777 www.airlanco.com

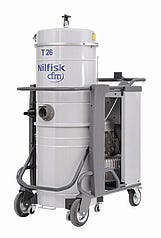

Three-Phase Vacuum Cleaners

Three-Phase Vacuum Cleaners

Booth 2252 - Comprised of the T26, T48, and T63 models, the CFM T Series three-phase, continuous-duty vacuum cleaners are constructed of heavy-duty steel and polypropylene. Ideal for collection of powders, dust, and debris, the vacuums are easy to use and maintain, even in the most challenging environments. Features and benefits include: a manual filter shaker that quickly removes caked on dust from the filter’s surface, maintaining the vacuum’s maximum suction power and improving productivity; a release lever lowers the wheeled collection container and acts as a handle for fast and easy disposal of collected debris. Nilfisk Industrial Vacuums, Morgantown, PA 800-645-3475 www.nilfiskindustrialvacuums.com

You May Also Like