Industry Products and Offerings

September 15, 2006

Conveying Magnets

Conveying Magnets

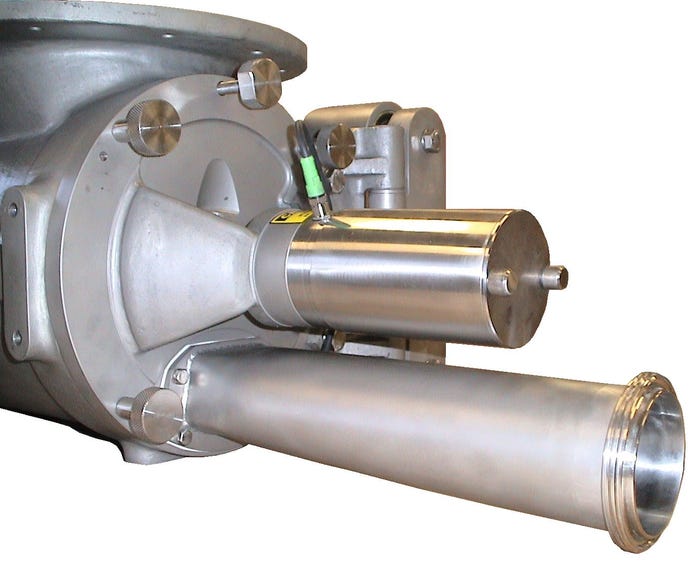

AIR-VEY Magnets are designed to remove ferrous contaminants from products in dilute phase pneumatic conveying systems operating at 15 psi or less. These units are used to ensure product purity and protect process equipment. The flow-through area of the housing is engineered to maintain the same product velocity with no appreciable drop in pressure. The magnets install easily in a horizontal, vertical or angled position with compression type couplings or weld in place.

Puritan Magnetics Inc., Oxford, MI 800-787-3624 www.puritanmagnetics.com

I ndustrial Ethernet Switches

ndustrial Ethernet Switches

Engineered for industrial use, these Ethernet Switches are available in 5- and 8-port managed or unmanaged versions with optional fiber capability. They feature DIN rail and wall mount design, redundant power input, reverse polarity protection, relay alarm output and an easy configuration design. The standard temperature spec is –10 to 70°C instead of the 0 to 60°C that is typical for many of the industrial products. They are designed to speed network integration while ensuring longevity and reducing downtime.

ASI, Carlisle, PA 877-650-5160 www.asi-ez.com Dust Collection Systems

Dust Collection Systems

Company’s Clean Air Systems provide source capture and ambient capture of silica and carbon particulate associated with thermal and acoustic insulation manufacturing. The systems can greatly reduce harmful particulate within a workplace, resulting in a more cost-efficient dust collection system. Dust collection systems can be custom engineered for insulation manufacturing applications. They can isolate problem areas within the workplace and can be tailored to extract hazardous materials such as silica, carbon and other particles that can be dangerous to the health and safety of employees. Roto-Pulse cartridge cleaning systems clean filter cartridges, cleaning 100 percent of the cartridge area.

Micro Air, Wichita, KS 866-566-4276 www.microaironline.com Weighing Terminal

Weighing Terminal

The IND429 weighing terminal offers connectivity and compliance for use in almost any application. With IP69K, this terminal is suited for use in the harshest environments. It is dust-tight and can be cleaned with high-pressure equipment used in the food and chemical industries.

Mettler Toledo, Columbus, OH 800-523-5123 www.mt.com

Quiet Impeller

Quiet Impeller

The marriage of precision injection molding techniques with modern high-strength plastic results in an impeller stronger than steel but less than half the weight. No longer limited to shapes that can be formed from flat pieces of metal, the TEK Impeller incorporates the compound curves and varying thickness necessary to achieve aerodynamic perfection. They are available in CW, CCW and DW, with matching inlet cones. They are quiet, efficient, durable and in stock. Features include aerodynamic perfection; computer-aided design; quiet, molded polyamide; efficient airfoil (BCA) design; non-overloading power characteristics; injection molding from high strength GRP polyamide.

Continental Fan Manufacturing, Buffalo, NY 800-779-4021 www.continentalfan.com  Colloid Mills

Colloid Mills

Greerco Colloid Mills are designed specifically to de-agglomerate solids and produce stable liquid emulsions in the micron particle range with consistent uniformity. These high-shear mixers are offered for continuous or batch emulsion or dispersion applications. They are ideal for a variety of applications in the pharmaceutical industry. Available in a wide range of sizes, models range from laboratory to heavy-duty production units. The vertical batch design is ideal for critical small-batch applications while the continuous design meets the requirements of higher capacity chemical emulsion reactions. A Serum Colloid Mill is also available for high-speed processing of fibrous and organic tissue used in pharmaceutical and food-processing applications. All contact metals are 316 stainless steel, and a sanitary 3-way valve permits final flow from the mill under controlled pressure, resulting in positive transfer.

Chemineer Inc., Dayton, OH 937-454-3200 www.chemineer.com Compact Electric Pressure Washer

Compact Electric Pressure Washer

Company offers a compact all-electric combination steam cleaner and high-pressure hot water washer that is ideal for cleaning chemical and pharmaceutical facilities. It is available for quick shipping and measures 39 in. x 18 in. x 44 in., featuring easy maneuverability in tight spaces in mixing, storage and shipping areas. It features two cleaners in one: 2.6 GPM at 1,200 PSI at 140°F for high-pressure hot water washing and 0.8 GPM at 100 PSI at 320°F for steam cleaning. Hot water will blast away dirt, grime and particles from mixers, drums, conveyors, loading docks, buildings and grounds. Steam will remove grease and oil, melt ice and disinfect surfaces.

Sioux Steam Cleaner Corp., Beresford, SD 888-763-8833 www.sioux.com Rotor Detection System

Rotor Detection System

Rotary valves used in pneumatic conveying applications have components that wear, which can result in the valve’s rotor vanes coming into contact with the valve body. If metal-to-metal contact occurs, metal fragments can break off and contaminate the product, causing costly shutdowns and product rejections. The Rotor Detection System (RDS) immediately alerts plant operators that metal-to-metal contact has occurred. RDS monitors electrical isolation between the rotor and valve housing. If a rotor vane touches the valve body—even if only for a split second—a warning is sent to personnel via the plant SCADA system and/or the valve is immediately shut down. RDS is available on new valves and can be retrofitted to existing valves.

Nu-Con Equipment, Chanhassen, MN 877-939-0510 www.nucon.com Laboratory Balances

Laboratory Balances

The new LA Reference series of laboratory balances offers precision weighing in 28 models with capacities ranging from 0.1 mg to 34 kg for any application. The proprietary monolithic weigh cell combined with microprocessor control in each unit reduces the influence of inside and outside temperature fluctuations. The balances have 14 application programs. All models offer isoCAL for fully automatic calibration and adjustment functions at regular or programmed intervals along with storage for up to 50 ISO/GLP-compliant records of these tests. Other advanced applications are available, such as the integrated SQmin program that provides compliance with USP section 41 for minimum sample quantity determinations. These results—as well as all other printouts—may be configured to suit individual SOP requirements.

Sartorius Corp., Edgewood, NY 800-635-2906 www.sartonews.com Low-Profile Vacuum Conveyor

Low-Profile Vacuum Conveyor

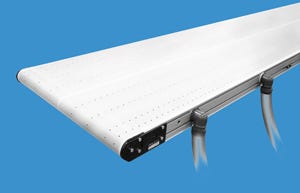

With a frame height as low as 1.87 in., the low-profile 2200 Series conveyor can fit in tight spaces. This low profile makes it ideal for a variety of applications, such as holding parts to the conveyor belt while moving up an incline or down a decline, or for securing parts to a fixed position on the conveyor’s belt for inspection, assembly and accurate feeding. Vacuum conveyors can also be used for upside-down applications and are made by perforating the belt and drawing air through grooves in the frame of the conveyor. Fast delivery times mean the conveyors and related accessories can be shipped to exact customer specifications in less than four weeks.

Dorner Manufacturing, Hartland, WI 800-397-8664 www.dorner.com Aggregate Diverter

Aggregate Diverter

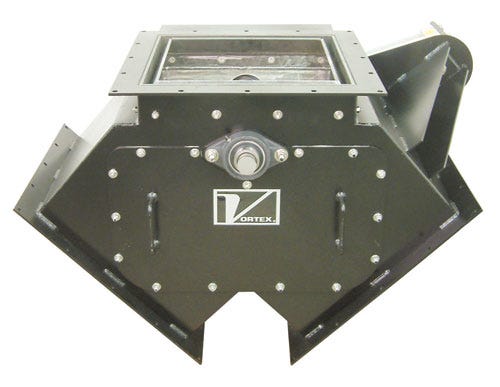

The Vortex Aggregate Diverter is designed to positively seal abrasive materials such as sand, gravel, whole grains and coal in gravity-flow applications. Engineered to eliminate problems associated with typical aggregate or “bucket” diverters, it incorporates two types of wear liners, forcing material to abrade upon itself, not the internal mechanisms. The inlet diverts material away from the bucket seals, and the “honeycombed” bucket deflector and chute liners minimize wear. Other features include a removable access door, allowing in-line inspection, a removable bucket and replaceable seals.

Salina Vortex Corp., Salina, KS 785-825-7177 www.vortexvalves.com Containment Control Systems

Containment Control Systems

CCS containment enclosures control the weighing and safe dispensing or sampling of powders to meet COSSH and GPM requirements. These floor-mounted enclosures feature HEPA filtered supply air and HEPA filtered exhaust air to ensure a clean contamination-free work zone for product protection and eliminate powders from discharging to the surrounding area. The exhaust air exits the enclosure on the rear wall low to the floor and/or at drum height. Speed controls are provided to balance the airflow and to compensate for filter loading. The enclosure is constructed of modular wall and ceiling panels for easy assembly. A front clear vinyl strip curtain entry allows pallets to be moved in. An air gap below the bottom of the strip curtains ensures an inward flow of air that sweeps across the floor. Fluorescent lighting, gauges and electrical are included.

HEMCO, Independence, MO 816-796-2900 www.hemcocorp.com Metal Detectors

Metal Detectors

S-Tron Metal Detectors remove both ferrous and nonferrous metals from pneumatically conveyed solids and feature Positive Speed Control, which automatically measures metal particle speeds and adjusts reject timing and duration to minimize loss of good product. Pinch valves prevent pressure loss during discharge. S-Tron Detectors use high-frequency, triple-coil detection for high sensitivity and have Product-Effect Compensation and EMFI filters to further cut product waste. They are engineered for easy installation and work on both vacuum and pressure systems. High-speed reaction times allow for a compact, space-saving design.

Bunting Magnetics Co., Newton, KS 800-835-2526 www.buntingmagnetics.com Vacuums

Vacuums

These vacuums are manufactured in portable, stationary and trailer designs. Horsepower ratings vary from 3 to 300. Standard vacuum pump drive is an electric motor, with LP gas, diesel or gasoline engines available as options. All models feature “no tools required” bag and cage removal system that permits one person to access these components in five minutes for inspection and permits removal and placement of bags and cages in 30 minutes. The bag or cartridge filter cleaning system is a state-of-the-art “on demand” system that pulses only if the differential rises to the cleaning range. The pulsing can be varied to contend with very fine dust. In addition to the standard models, special features like explosion-proof construction, HEPA filters, special paint and rotary valves are available.

Multi-Vac, Union Grove, WI 262-878-0366 www.multivacinc.com Conveying Elbow

Conveying Elbow

The Smart Elbow for pneumatic and slurry conveying systems reduces costly maintenance and downtime by eliminating elbow wear, plugging and product degradation such as streamers and fines. Due to its design, conveyed material changes direction by deflection rather than impact with the elbow walls or impact with a filled “pocket.” The design gives it a true deflection zone that allows conveying lines to operate years rather than months before elbow maintenance is required, eliminating frequent plant shutdowns caused by elbow wear or plugging. Free trials and one-year warranties are available.

HammerTek Corp., Landisville, PA 800-505-9665 www.hammertek.com Anti-Slip Stair Treads

Anti-Slip Stair Treads

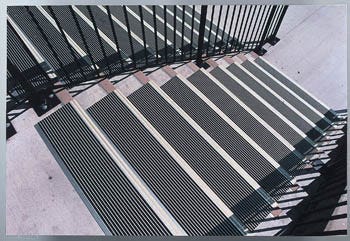

Worn stairs can result in injuries, fatalities and lawsuits. Treds can make worn-out stairs safe without costly rebuilding. Made from heat-resistant extruded aluminum alloy, their aluminum oxide grit—second in hardness to diamonds—provides long-lasting traction. They are custom cut for a perfect fit and can be applied to any type of stair—concrete, wood or metal. Fast, easy installation allows normal stair traffic to resume quickly.

Garon Products, Wall, NJ 800-631-5380 www.garonproducts.com

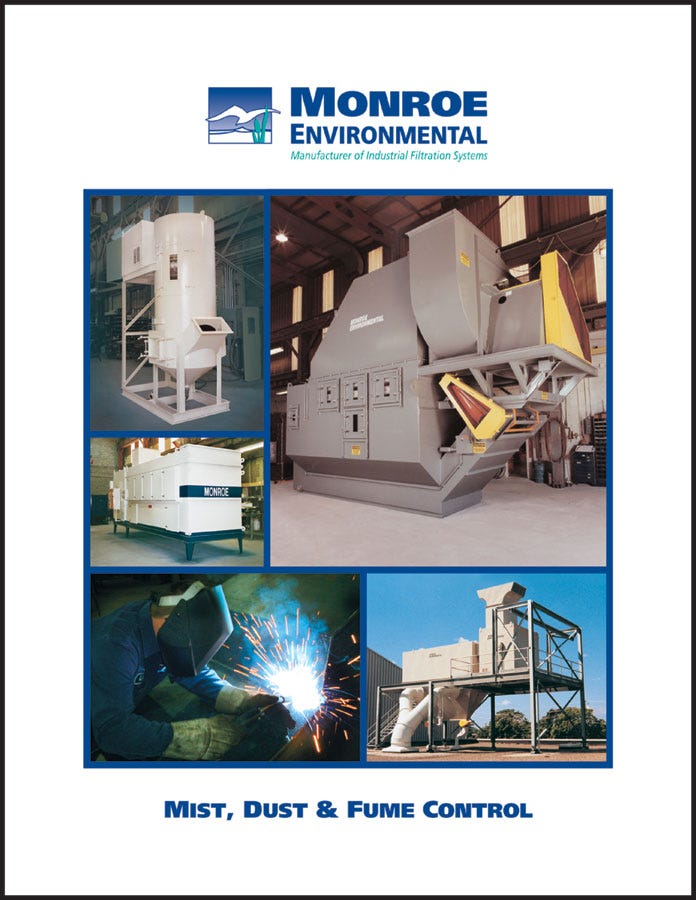

Mist, Dust & Fume Control Equipment

Mist, Dust & Fume Control Equipment

Company offers a complete line of mist, dust and fume control equipment that includes mist collectors, air scrubbers and dry dust collectors. Air scrubbers provide wet processing to clean air of solid particulate fumes, chemical odors and contamination from process exhausts up to 2,200°F. Three types of mist collectors are available—spiral tube, multi-stage and coalescing. These units are typically used for oil mist, smoke and vapor removal. A new cartridge dust collector is available with efficiencies up to 99.9+ percent. Vertical cartridge dust collectors with 500 to 50,000 CFM capacity, modular construction, easy maintenance and up to 350°F endurance are available.

Monroe Environmental, Monroe, MI 734-242-7654 www.mon-env.com Flow Meter

Flow Meter

CentriFlow Meters provide measurement accuracies of ±0.25 percent, with no moving parts, high uptime and fast payback, providing mass flow measurement and process control. It handles free-flowing bulk and powder solids and is based on the principle of centripetal force. Applications are in the food, petrochemical, and agriculture industries for mixing, blending, seasoning, packaging and load out. The unit is available in several stock configurations and in custom-engineered-to-order designs for special requirements, such as food sanitation and high-temperature applications.

Eastern Instruments, Wilmington, NC 910-392-2490 www.easterninstruments.com Racetrack Endloader

Racetrack Endloader

This automated system for flow-wrapping, collating and packing confectionery bars into end load cartons is now working in New Zealand on cereal and health bars. End load cartoning delivers high-speed packing line performance with lower machinery costs than robotic top load systems, with the added bonus of savings of packaging materials and factory space. The unit in New Zealand collates product, erects, loads and seals endload cartons at speeds of 260 bars/min with the option to increase to 310 ppm. The integrated installation combines a single station automatic distribution system with in-line bar turning and shuttle phase feeder. It also has a Flowtronic 120 flow wrapper from Autowrappers with a Bradman Lake twin racetrack collator/loader and SL902 indexing end load cartoner.

Bradman Lake Inc., Charlotte, NC 704-588-3301 www.bradmanlake.com.jpg?width=700&auto=webp&quality=80&disable=upscale) Air-Operated Conveyors

Air-Operated Conveyors

High-Temperature Line Vac Conveyors convert hose or tube into a powerful in-line conveying system for high-temperature materials up to 900°F. These air-operated conveyors eject a small amount of compressed air to produce a vacuum on one end, resulting in high output flows on the other. Construction is durable type 303 stainless steel. Applications include sampling hot flue gases; exhausting fumes; and conveying soot, ashes and hot debris. Other models for hopper loading, scrap trim removal, tablet transfer and packaging are available. Prices start at $284.

EXAIR Corp., Cincinnati, OH 800-903-9247 www.exair.com Screenings Conditioner

Screenings Conditioner

The Spiralift SC8500 Screenings Conditioner (SC) offers the same effective washing performance as the larger SC1600 but with a lower headroom profile for smaller applications and installation in tight plant locations. The unit takes screenings discharged from a bar screen and washes, grinds, compacts, de-waters and discharges them into a container for disposal. In operation, screenings drop into the SC hopper where they are washed by the upper spray nozzles and then finely ground by a 5 hp Taskmaster TM8520 shredder. The Spiralift conditioner’s intensive spray wash system rinses organics from sceenings and flushes them back into the system flow. The screenings are then dewatered in the unit’s press zone and pushed through the “elephant trunk” discharge tube. The grinder and press technology, along with rugged construction, makes the unit effective and durable.

Franklin Miller Inc., Livingston, NJ 973-535-9200 www.franklinmiller.com Large-Format Thermal Transfer Coding Systems

Large-Format Thermal Transfer Coding Systems

Capable of producing a large print area and featuring a print engine that can be turned in the frame, the NGT Series of large-format thermal transfer coding systems maximizes production flexibility and increases print cycle speeds while reducing the cost of spare parts and consumables for large-format coding applications. Within the NGT Series, there are four intermittent motion (IM) coders and one model—the NGT 6 CM—that operates in either intermittent motion or continuous motion mode with quick conversion. The design of the coders allows for the rotation of the print engine within the print module’s frame.

Norwood Marking Systems, Downers Grove, IL 800-626-3464 www.itw-norwood.com

Magnetic Equipment

Magnetic Equipment

A full line of magnetic equipment solves most application requirements. A wide range of standard products with EZ CLEAN and POWR CLEAN features are available. Custom designs are also available to solve even the most difficult applications.

Puritan Magnetics Inc., Oxford, MI 800-787-3624 www.puritanmagnetics.com Extreme Air Downdraft Tables

Extreme Air Downdraft Tables

These Extreme Air Downdraft Tables provide clean, easy, powerful solutions to indoor air pollution problems. They are self-contained, powered downdraft tables that do not require external exhaust hoses, offering flexibility and portability without the need for ducting. They are designed for welding, grinding, soldering, sanding, painting, pouring and various other industrial applications, drawing contaminants away from worker vision and breathing zones, increasing work quality while reducing hazards to workers in the surrounding areas. They feature 99.99 percent efficient cartridge filters. They come with a built-in tool tray, an energy-efficient EPACT motor and the exclusive Roto-Pulse cartridge cleaning system. They offer quiet operation that far exceeds OSHA standards. An optional backdraft hood is also available.

Micro Air, Wichita, KS 866-566-4276 www.microaironline.com Direct Contact Foil-to-Container Induction Sealing

Direct Contact Foil-to-Container Induction Sealing

This “foil direct” (capless) induction sealer offers packagers a cost-effective sealing solution for applying a foil barrier or protective seal when a cap is not required or when it’s advantageous to seal the container before applying a cap. Primary benefits of the capless sealing technology include the ability to seal a wide variety of container shapes and sizes. The units can be mounted vertically or horizontally. The company can design systems flexible enough to be incorporated into several configurations including rotary filling, bench-top (table) systems or even “pick, place and seal” applications. Primary features include its lightweight, streamlined design; high efficiency; solid-state construction; and 120V or 240V operation. The unit is stability tested and certified.

Pillar Technologies, Hartland WI 262-912-7221 www.pillartech.com.jpg?width=700&auto=webp&quality=80&disable=upscale) Dense Phase Pneumatic Conveyor

Dense Phase Pneumatic Conveyor

A key feature of this dense phase conveying system is its exclusive air management system. By using a pressure control regulator, airflow control orifice and bypass valve, total air flow to the system and product-to-air ratio (the combination of air flow and conveying rate) are automatically controlled at the vessel. This system saves money and allows easy access because all controls are located on the pot. It provides for easy installation.

Smoot, Kansas City, KS 800-748-7000 www.magnumsystems.com

Blower Packages

Blower Packages

Positive-displacement blower packages come in pressure, vacuum and combination models to accommodate any dilute phase pneumatic conveying situation and the heat sensitivity of the conveyed material. They are completely self-contained for easy installation and feature heavy-duty frames, adjustable motor bases, and inlet and outlet silencers for a quieter working environment, indoors or out. For safe operation, each unit has an air filter, relief valve, pressure gauge and check valve.

Airlanco, Falls City, NE 800-500-9777 www.airlanco.com

Trough Conveyors

Trough Conveyors

These heavy-duty, tower-type cable-suspended radial stackers are from 18-in. to 84-in. wide. They are trough conveyors with the ability to turn from a point on an arc and build storage piles. The company manufactures underslung and mast styles and uses computer-aided design, modular construction and jig-built trusses to ensure a square and true design. Stackers are engineered for heavy-duty performance. Bucket elevators, Combo-Flite Conveyors, Overland systems, picking and sorting conveyors, and tire recycling conveyors are also available.

Dover Conveyor Inc., Midvale, OH 740-922-9390 www.doverconveyor.com Particle Shape and Size Analyzer

Particle Shape and Size Analyzer

The Sysmex FPIA-3000 automated particle shape and size analyzer now includes the facility to measure particles suspended in non-aqueous solvents, as well as those in water-based materials. This is important in the pharmaceutical and chemical industries where there is often a requirement to measure the shape and size of particles that are soluble in water. The analyzer can now accommodate all common solvents, including acetone, methylethylketone, ethyl acetone, xylene and toluene. The fully automated instrument can measure particles in the range 0.8 to 300 microns and delivers both particle size and shape information. Using a CCD camera, the system produces images of each particle and provides a scattergram of shape index versus particle size in just 2.5 minutes.

Malvern Instruments Inc., Southborough, MA 508-480-0200 www.malvernusa.com High-Volume Laser Sorter

High-Volume Laser Sorter

Featuring a doublewide platform that harnesses the horsepower of Key’s G6 engine, the high-volume Optyx 6000 Series Sorter with Raptor Laser Technology detects the smallest defects and foreign material to optimize product quality and maximize food safety at double the throughput of the predecessor model. It can sort fresh, frozen and dried fruits and vegetables, including frozen potato products, tree nuts, raisins and other food products at production rates of up to 40,000 lbs/hour, depending on the application. It features a 48-in.-wide scan area that doubles production capacity and all-digital state-of-the-art electronics that deliver the same ultra-high resolution as the Optyx 3000 Raptor.

Key Technology Inc., Walla Walla, WA 509-529-2161 www.key.net

Handheld Terminal

Handheld Terminal

The Allen-Bradley GuardPLC handheld terminal helps maintenance workers program and configure Allen-Bradley GuardPLC safety controllers and I/O modules without having to bring a PC to the plant floor. This device can reduce downtime, increase control system security and maintain high productivity at manufacturing sites. Commissioning a GuardPLC controller or I/O module is as simple as plugging the terminal into the device and reloading the program. The application program and data can be downloaded to the GuardPLC from the handheld terminal, eliminating the complexity found in programming software packages.

Rockwell Automation, Bloomington, MN 800-223-5354 www.rockwellautomation.com![]() Manual Dumping Station for Pneumatic Conveyors

Manual Dumping Station for Pneumatic Conveyors

This manual dumping station for pneumatic conveying systems collects dust created during manual dumping of powder and bulk solid materials from bags, boxes, drums and other containers. The hopper is configured with a non-flow-through pick-up adapter for introducing material into vacuum pneumatic conveyor lines. The unit features a high-velocity vacuum fan that draws airborne dust from the operator’s atmosphere onto two cartridge filters. Automatic reverse-pulse filter cleaning allows continuous, efficient operation. Timer-activated solenoid valves release short blasts of compressed plant air inside cartridge filters, causing dust build-up on the outer filter surfaces to fall into the hopper.

Flexicon Corp., Bethlehem, PA 888-353-9426 www.flexicon.com ActiveX Controls

ActiveX Controls

Company now offers ActiveX controls. The Microsoft Windows-based object provides the customer with a graphical user interface (GUI) on their HMI package. With the ability to be placed into any new or existing HMI package, the ActiveX control provides immediate access to the company’s Disocont control, reduces customer integration time and provides all the important feeder functions, parameters and calibration setup through the GUI. By providing a direct mode of communication from the HMI to the Disocont control, users are able to bypass the PLC. This reduces the number of programs that need to be written to the PLC and scan time on the PLC. The ActiveX control is also compatible with various HMI platforms such as Excel, Wonderware, Labview, DHMTL, GE Simplicity, Siemens, WINCC, and AB RSView, which means the customer only needs to have a single HMI interface package.

Schenck AccuRate, Whitewater, WI 800-558-0184 www.accuratefeeders.com Bag Stabilizer

Bag Stabilizer

Lock n’Pop is an industrial product that performs like the glue on Post-it notes. The adhesive’s high-shear strength ensures that slippery bags don’t shift during palletizing, interplant handling or shipment, yet come apart easily with no apparent residue. It can reduce—and often eliminate—the need for stretch wrap. In addition, it continues to perform even as layers are removed, while stretch wrap once removed, leaves remaining layers vulnerable to slippage—especially when the pallet is moved.

Lock n’Pop, Lynnwood, WA 800-225-3009 www.locknpop.com

Twin Shaft Grinders

Twin Shaft Grinders

Annihilator grinders are twin shaft solids-reduction units designed to ensure that harsh solids in the primary sludge stream are ground uniformly and efficiently. They provide trouble-free performance in a variety of industrial and municipal applications, protecting downstream equipment from being plugged or damaged from large solids, reducing expensive repairs. To avoid costly downtime and expensive, unnecessary repairs resulting from complete bearing/seal cartridge designs found on other twin shaft grinders, they now provide the mechanical seal and the bearing on separate stainless-steel sleeves. This exclusive design allows for quick on-site replacement of worn components without purchasing complete cartridge designs.

Moyno Inc., Springfield, OH 877-486-6966 www.moyno.com Packing Slip System

Packing Slip System

With the launch of the Autoslip Express packing slip system, distribution centers can now increase productivity at packing stations without causing large disruptions in operations or having to further allocate space for large machinery in already crowded warehouses. Designed specifically for the packing station, it is a stand-alone version of the company’s inline Autoslip packing slip system. On demand, the Express prints, folds and inserts up to four shipping documents into an adhesive pouch. The “tamper proof” pouch is applied to the shipping box by the packing station operator. Automating the creation of packing slips allows packing station operators to be twice as productive as the manual creation process. An Autoslip Express is seamlessly integrated into an existing warehouse with minimal downtime.

PSI Engineering, Mississauga, Ontario, Canada, 800-774-5758 www.psiengineering.com

You May Also Like