- Dust Collection

- Plant Asset Management

- Explosion Protection & Safety

- Occupational Safety

- Safety & Compliance

Industrial Combustible Dust Solutions

If your dust is combustible, you need to add explosion protection components to your dust collection system.

June 10, 2021

John Milius, business development manager, Parker Hannifin Corp., Industrial Gas Filtration and Generation Div.

All manufacturing facilities create dust of one type or another. If your manufacturing facility is creating combustible dusts, NFPA (National Fire Protection Association) 652 defines the standard for a dust hazard analysis (DHA) for your dust or dusts, and the requirement and enforcement of the DHA is through a regulatory agency such as OSHA or the Authority Having Jurisdiction (AHJ). Your DHA is a methodical review of your dusts with the intent to both identify and evaluate the risk of fire and explosion hazards within a facility or process handling combustible dust. If your dust or dusts are combustible, you will have to add explosion protection components to your dust collection system. The data in your DHA will determine the combustibility and explosivity characteristics of your dusts such as Kst, Pmax, MIE, and MEC values.

The NFPA 652 requirement for the completion of the DHA means that you should have your DHAs on record now. If tests reveal that your Kst value is greater than zero, then review with experts of dust control solutions for how to safely and effectively handle the collected dust.

When comparing manufacturing operations, 53% of all primary dust explosions happen within dust collectors.1 These explosions can result in secondary explosions in or around the facility. Explosions can be devastating and can be avoided. Know your options.

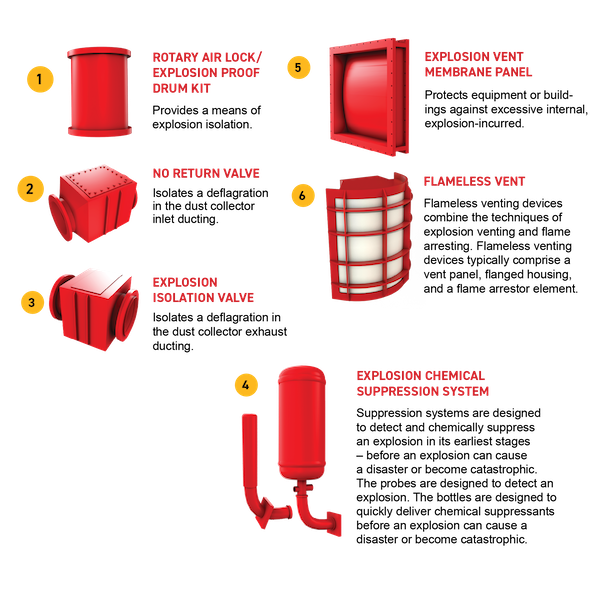

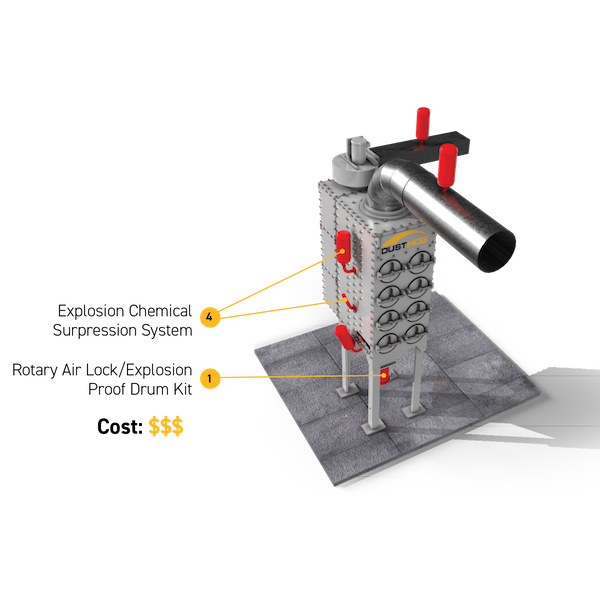

Explosion Prevention Terminology - Product Key

(Note: Illustrations are only depictions of available product on the market and are not representative of any manufacturers design. Illustrations by Justin Scricco, Parker Hannifin)

How Combustible is Your Dust?

The explosibility of your dust will dictate the type of explosion protection components will be needed. The location of your collector, inside or outside, or if you are recirculating the air back into the building, will also dictate the type of components that would be required. This guide will allow you to select the appropriate components depending on where your collector is located.

Once you have assessed your dust or dusts for Kst, Pmax, MIE, and MEC values, this will determine what NFPA components will be required. Once that is established then the design of the dust collection system can be initiated, followed by the appropriate operation and maintenance of such system. Please be sure to enlist the assistance of a qualified air pollution control company or contact Parker directly at www.parker.com/airquality.

The following are specific examples of dust collector systems that require explosion-related devices. All dust in examples are greater than 0 Kst.

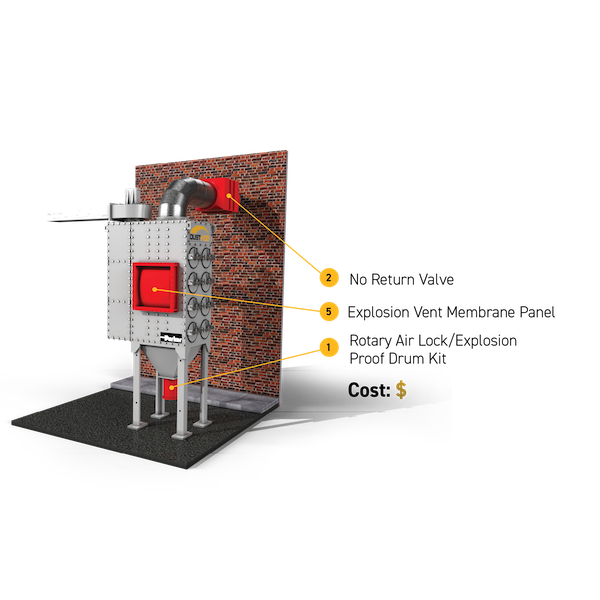

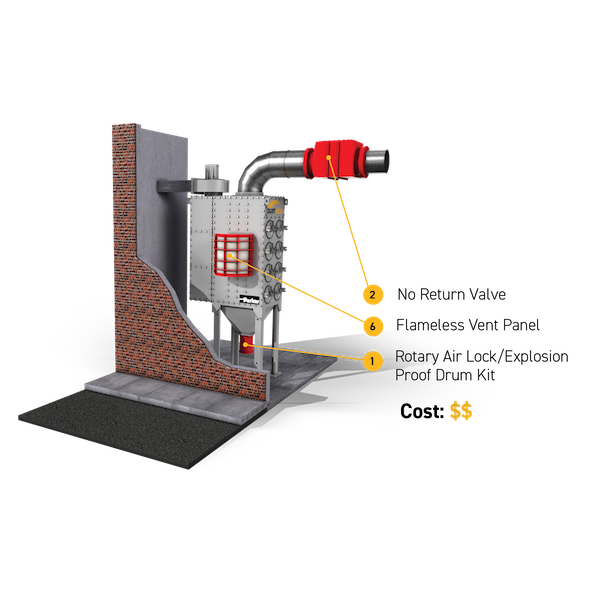

1. • Collector located outdoors

• Ducted from inside to outside

• Air discharged outside

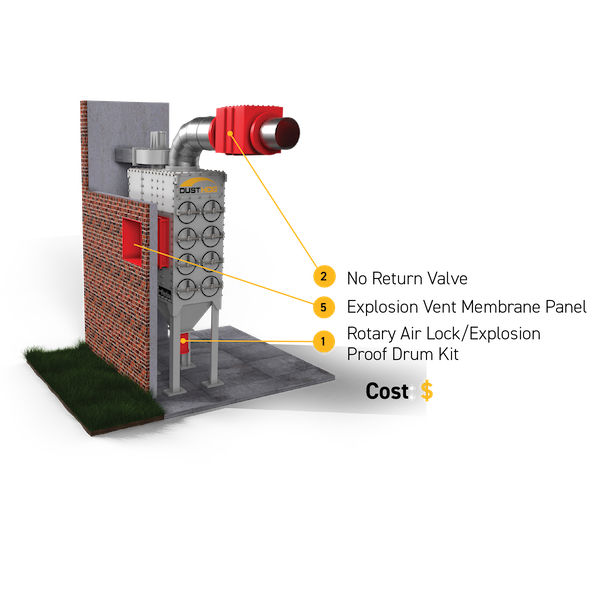

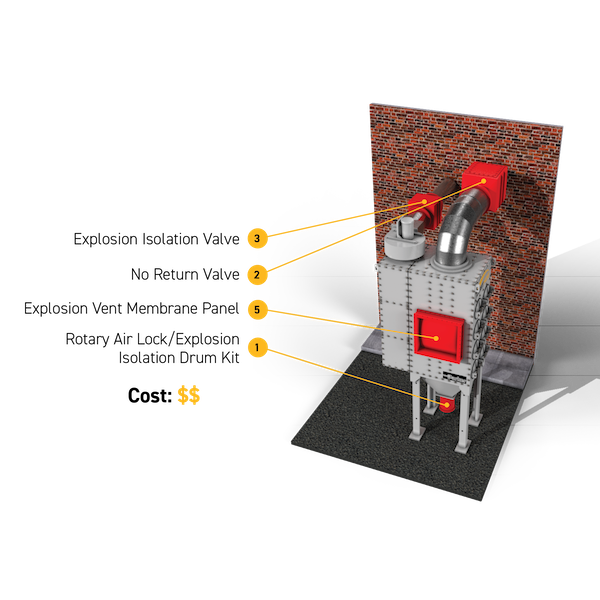

2. • Collector located indoors

• Ducted from inside to inside

• Air discharged outside

• Explosion vent ducted outside

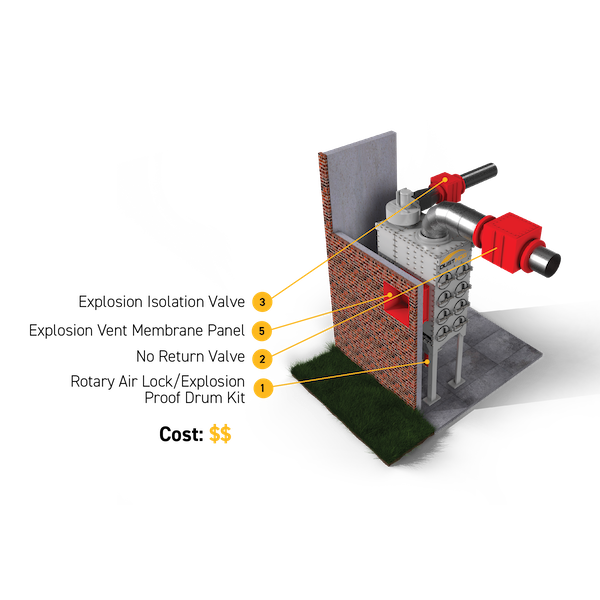

3. • Collector located indoors

• Ducted from inside to inside

• Air discharged outside

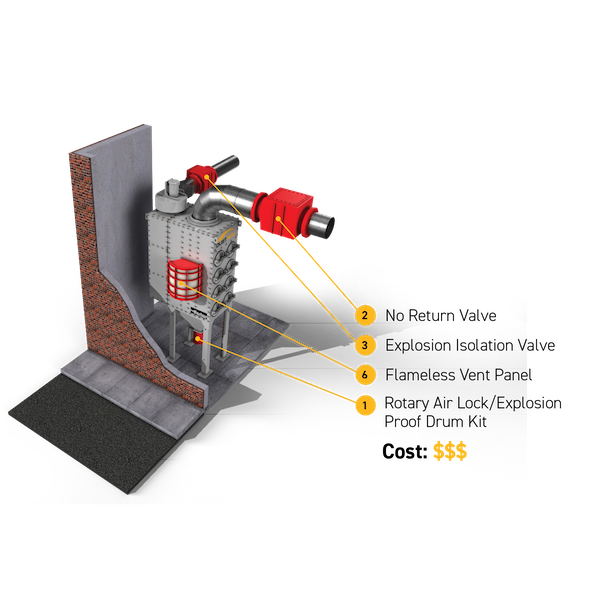

4. • Collector located outdoors

• Ducted from inside to outside

• Air returned inside

5. • Collector located indoors

• Ducted from inside to inside

• Air discharged inside

6. • Collector located indoors

• Ducted from inside to inside

• Air discharged inside

7. • Collector located indoors

• Not adjacent to outside walls

• Ducted from inside to inside

• Air discharged inside

Summary

It is important to understand and follow NFPA guidance in selecting equipment for your intended application, including required safety devices and testing your dust to determine combustion hazards. Sample collection and testing are available.

John Milius is business development manager, Parker Hannifin Corp., Industrial Gas Filtration and Generation Div. (Lancaster, NY). For more information, call 800-343-4048 or visit www.parker.com.

1 “Combustible Dust: DHA and Other Methods for Prevention,” Powder & Bulk Solids, November, 2020

You May Also Like