Establishing a Dryer Champion to Maximize Process Yield, Efficiency

Knowledge and resources are necessary to optimize and maintain drying equipment

November 29, 2021

Al Worthington, process engineer, Buhler Group

A universal goal of any manufacturer is to keep its plant running smoothly while generating as much profit as possible. As a dryer manufacturer, Bühler is frequently asked to assist customers in optimizing their dryers and helping them improve their process. A dryer optimization can include adjustments to process conditions such as retention time and fan speeds, production parameters such as feed rate and product bed depth, or mechanical adjustments to dampers or internal panels. These changes are focused on improving product quality and reducing the energy consumption of the dryer. In many cases, however, shortly after the Bühler technician leaves, the equipment returns to its previous operating conditions and is again poorly utilized. In order to sustain optimal long-term dryer performance, managers need to ensure that their personnel have the appropriate knowledge, resources, and motivations to optimize and maintain their drying equipment.

The Importance of Optimization

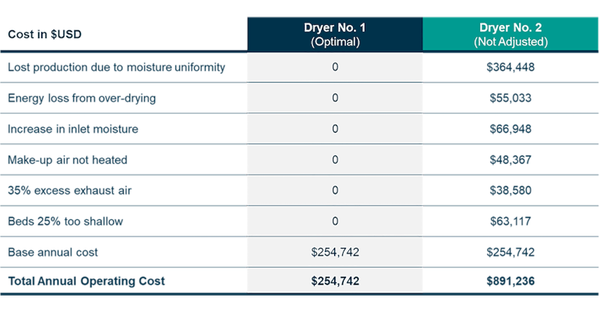

Dryers are typically the most energy-intensive equipment in a process line, and relatively small increases in efficiency can have significant payback. To reinforce the importance of dryer optimization, consider the following example of pet food dryers. Dryer energy usage and configurations vary widely across industries, but pet food dryers provide a good baseline example. The below example shows how quickly an unoptimized dryer can accumulate additional costs. This calculation was performed for a hypothetical pet food company with the following baseline criteria that are typical of what would be seen in the industry. Additional specifications for this example can be found in Appendix A.

Production Targets:

* 12,500 kg/hr infeed production rate

* Target moisture drying from 24% to 9% wwb

As the above demonstrates, energy inefficiencies in dryers can accumulate quickly and result in large operating expenditures over the course of a year. Energy evaluations that have been performed on two-pass pet food dryers with production rates greater than 12,000 lb/hr (~5,800 kg/hr) over the past several years have all shown yearly savings potentials greater than $50,000. These savings come from a combination of mechanical improvements and process changes that are directly related to the gas or steam usage of the dryer. Losses in operating efficiency--up to 25%--are common in older drying equipment. These losses are compounded by additional revenue lost from operating a dryer below the maximum production rate. Reductions in capacity can easily total hundreds of thousands of dollars over the course of a year. If there is so much potential savings, then why are un-optimized dryers so common?

Key Criteria for Sustaining Optimization

Championing Process Knowledge

The first key component to maintaining an optimized dryer is having the knowledge to make process changes when required. Production lines are rarely completely steady-state, and changes must be made frequently to account for changes in production rate or incoming product quality. In some cases, significantly different products may be processed on the same machine and settings will need to be changed to adjust for the differences. The dryer will commonly be set to the lowest common denominator (i.e. whatever settings will successfully run every product or rate without requiring further changes). Often, this is because operators or personnel don’t feel comfortable enough with the equipment to risk making changes. Training on dryer basics and operation can help operators better understand the equipment and allow them to feel more comfortable making more frequent changes to help improve efficiency. Dryer basics include things like understanding air properties, discussing how moisture evaporates from a product, and reviewing internal dryer layouts. To maintain consistency between operators or shifts, many plants find it helpful to generate recipes or spec sheets of the optimal settings for different recipes or rates. Almost any plant will already have recipes for process conditions such as temperature or retention times, but very few also include changes to account for production rates, damper positions, or product spreader settings.

Ensuring Employees Have Resources

The second most important criteria for maintaining dryer optimization is ensuring that employees have the resources required to implement changes, such as time and money. Plant personnel are typically familiar with the equipment. They operate it every day and are familiar with most aspects of it, especially mechanical ones. They know what components are troublesome and what are the most likely to break or malfunction. In many facilities, operators are aware of the issues that are reducing the effectiveness of the dryer, but do not have the resources to properly maintain the equipment. Most commonly there is a lack of time to be able to dedicate to performing repairs, inspections, or preventative maintenance tasks. Many plants try to minimize downtime, which means process lines are only stopped long enough for a quick cleaning between production runs. Inspections of equipment to look for missing internal panels, broken hinges, or damaged bedplates are not likely to occur unless specifically scheduled by management.

Rewarding Process Efficiency and Results

This leads to the final point, which is that employees need the motivation to optimize a dryer. Factory operators are generally tasked with monitoring and operating several pieces of equipment in a process line. However, incentives rarely exist that encourage employees to take the initiative to constantly make sure the dryer is operating as efficiently as possible. The “success” of a shift is often measured on the throughput of sellable product, with efficiency rarely being considered. Factories are commonly seen using natural gas burners without having a way of measuring gas consumption for the dryer at all. If employees are graded on efficiency (or additionally rewarded for sufficiently high efficiency results) they will be much more likely to put in the extra effort to adjust and inspect the equipment to make sure it is running as efficiently as possible. This will allow the dryer to produce more consistent product, use less energy, and reduce downtime from unexpected or long-standing issues.

Summary

Production lines are expensive to operate, and the dryer is usually the most expensive equipment to run. Even small improvements in efficiency can result in significant savings. In order to realize the savings potential, managers should ensure that operators and plant personnel have the knowledge to feel comfortable making process changes, the resources to properly fix damaged equipment, and the motivation to take the time to verify and inspect equipment to keep it running as efficiently as possible in the long term. A single individual with deep knowledge of the drying process can be effective in achieving sustained optimized dryer performance. However, support from the rest of the organization is required for a facility to operate at its maximum potential.

Al Worthington is process engineer, Buhler Group. He can be reached at [email protected].

Appendix A:

The pet food example shows how quickly an unoptimized dryer can accumulate additional costs. The calculations were performed for an example pet food company with the following criteria:

* 12,500 kg/hr infeed rate

* Target final product moisture of 9% wwb

* Estimated energy cost of 0.0171 $US/kWh

* Production time of 24 hr/345 days

Dryer 1 (optimized)

* 12,500 kg/hr infeed production rate at 24% wwb moisture

* Discharge moisture uniformity of +/-1% wwb

* Supply air for heat zones is exhaust air from the cooler at 60°C

* Exhaust air humidity of 0.1 kg water/kg dry air

* Retention time on beds 1 and 2 of 8 and 12 minutes, respectively, at 150°C

Dryer 2 (not optimized):

* 12,500 kg/hr infeed production rate at 27% wwb (3% higher than dryer 1, could be caused by extruder issues)

* Discharge moisture uniformity of +/-3% wwb, leading to a target discharge moisture of ~7% (typically caused by poor airflow uniformity or incorrect bed depth settings)

* Supply air is ambient air at 20°C

* Exhaust air humidity of 0.76 kg water/kg dry air (35% excess, likely due to incorrect damper settings)

* Retention time on beds 1 and 2 of 6 and 9 minutes respectively at 220°C (Note that this temperature is not feasible to run on a real pet food dryer; this temperature is due to the energy usage that would be required to hypothetically dry this amount of product within the above parameters. On a real system, the production rate would have to be lowered to compensate.)

You May Also Like