Effective Homogenization and Densification of Powders of Differing Densities

The intensive nature of this style of mixing will achieve these results in a shorter period of time than other mixing technologies

January 19, 2023

A common challenge faced by many customers is mixing two or more materials of differing densities into a uniform and homogenous mixture. Insufficient mixing can lead to particle segregation and de-mixing during transport or storage.

The Lancaster line of high-shear counter-current mixers excel at the rapid homogenization of bulk powders, including those of differing densities. For some applications, dry mixing operations can be as brief as 30 seconds or less.

This case study will demonstrate how Lancaster Products high-shear counter-current mixers can effectively homogenize these powders into a uniform mixture, while increasing the overall mixture density in the absence of added moisture. The counter-current mixing action is achieved by rotating the mixing rotor and mixing pan in opposite directions. Strategic manipulations of the speeds of the mixing tools can produce a uniformly homogenous mixture in a short period of time.

Materials & Methods

For this test case, a Lancaster Products K-1, high-shear counter-current mixer was used to homogenize and densify silicon carbide and ultra fine silica in the absence of additional moisture. Tool RPMs of 1,640 RPM and 20 RPM were used for the rotor and mixing pan respectively.

The raw powders used during this mixing study were silicon carbide at a loose bulk density of 1.45 g/ml and ultra fine silica at a loose bulk density of 0.10 g/ml. The batch size for each mix case was 6 liters.

Case #1: 50-50 silicon carbide to silica by volume

Case #2: 50-50 silicon carbide to silica by mass

Homogenization Period

The powders were mixed in a counter-current high shear mixer for ten 30-second intervals that were performed consecutively for a total time of 300 seconds. At the end of each 30-second interval, four loose bulk densities were measured and then averaged to calculate the average loose bulk density of the mixture. These average densities were then plotted versus total mix time.

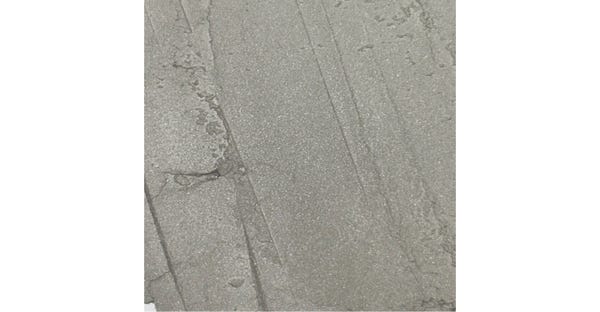

Evaluating Homogeneity

The smear test was utilized to evaluate the physical characteristics and determine homogeneity of the mix. A small quantity of material was placed on a uniform background and smeared to a fine uniform layer. Any non-uniform areas or nodes of unmixed powders were identified. Once no nodes are present, the material is assumed to be homogenous.

Extended Densification Period

Once the homogenization period was completed, a densification trend was observed in both test cases. The following mixing schedule was performed to determine how the mixture density would change during an extended mixing period without the addition of moisture.

A total of 10 individual intervals of increasing duration were completed consecutively with the first lasting 30 seconds and the final lasting 300 seconds for a total combined mixing time of 1650 seconds. Each individual interval was 30 seconds longer than the previous interval. Note: The density calculations cover the entire combined 1950 seconds of mix time.

Results

Homogeneity – Reaching Uniform Density

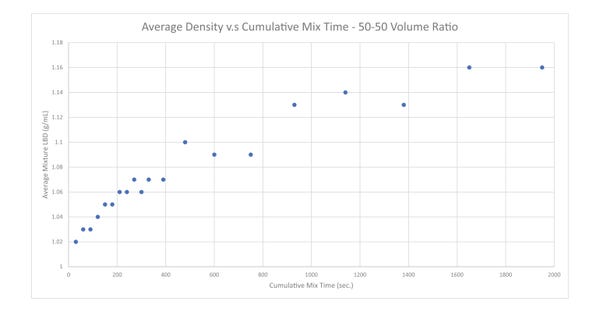

By Volume

In the case of a 50-50 volume ratio, the mixture contained a high mass bias of silicon carbide. For each recorded density point, a quantity of four measurements were taken and then averaged. Consecutive density measurements at the 210-, 240-, 270-, and 300-second marks indicate that mixture homogeneity has reached a steady state. Therefore, the mixture reached complete homogeneity after 210 seconds.

Upon visual inspection, the mixture was a uniform color, slightly lighter in tone, and contained zero “nodes/patches” of white powder when spread flat.

In Figure 2, the white silica is thoroughly dispersed throughout the silicon carbide.

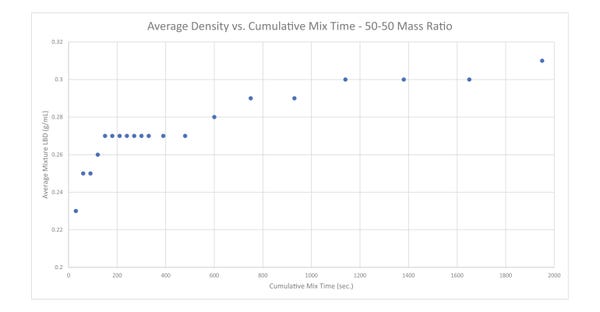

By Mass

In the case of a 50-50 Mass ratio, the masses were balanced. Over the allotted mix interval, the densification trend happened more rapidly than the volume ratio mixture. Again, each density point was determined by an average of four measurements. Consecutive density measurements at the 150-, 180-, 210-, 240-, 270-, and 300-second marks indicate that the mixture reached a steady state. Therefore, the mixture reached complete homogeneity after 150 seconds.

Performing the same smear test revealed a homogenous mixture. The sample in Figure 3 is lighter gray in color due to the larger amount of silica present. The presence of the white silica is much higher than the 50-50 by volume case. However, the silica is still evenly and thoroughly dispersed throughout the mixture.

Densification – Increasing Mixture Density without Liquid Addition

In the 50-50 by volume case, the mixture density increased by 3.9% after the first 300 seconds with an additional 8.4% increase after the entire mixing session was completed.

Total Density Percent Increase = (1.16-1.02)

----------- × 100% = 13.7%

|1.02|

In the 50-50 by Mass case, the mixture density increased by 17.4% after the first 300 seconds with an additional 14.8% increase after the entire mixing process was completed.

Total Density Percent Increase = (0.31-0.23)

----------- × 100% = 34.8%

|0.23|

Conclusion

For these specific test cases, complete homogeneity was achieved in an average time of three minutes when based upon density uniformity. The densification trend became stable and levelled off after an average of 23 minutes of mixing time.

Lancaster Products high-shear counter-current mixers can effectively homogenize and densify powders of vastly different densities. This also holds true when mixing a very small amount of one material into a large amount of a second material. The intensive nature of this style of mixing will achieve these results in a shorter period of time than other mixing technologies.

For more information, contact Lancaster Products (Lebanon, PA) at 717-272-2111, or visit www.lancasterproducts.com.

About the Author(s)

You May Also Like