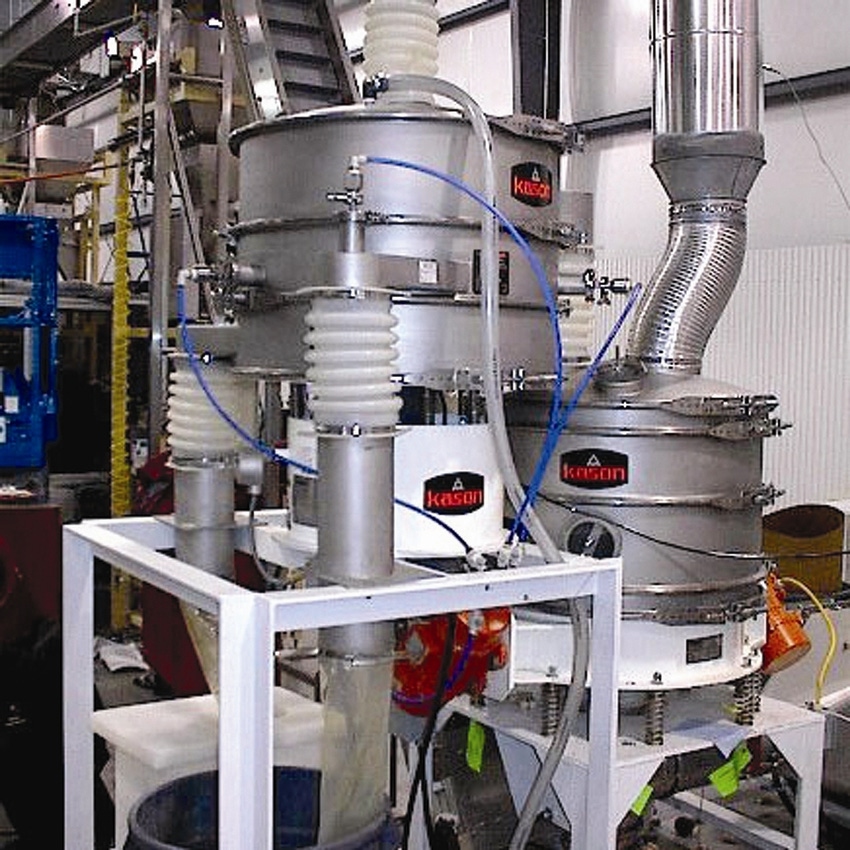

Dewatering-Drying System with Vibratory Screener

January 30, 2012

This dewatering-drying system consists of a 30-in.-diam circular vibratory screener that removes oversize and undersize particles and up to 50 gal of water per minute, integrated with a 40-in.-diam circular fluid bed dryer that dries up to 700 lb of on-size particles per hour. The screener's vibratory action causes oversize particles to discharge through a spout at the upper screen's periphery, on-size pellets to discharge through an extended spout at the lower screen's periphery, and undersize fines and water passing through the lower screen to discharge through a third spout. The circular (versus rectangular) configuration of the fluid bed dryer consolidates system components, eliminates the need for heavy-gauge walls and braces, has fewer weld seams, cuts cleaning time 50+%, allows downsizing of vibratory motors, requires only one air inlet and outlet, and reduces cost, especially when finished to 3-A, FDA, and BISSC standards.

Kason Corp., Millburn, NJ 973-467-8140 www.kason.com

You May Also Like