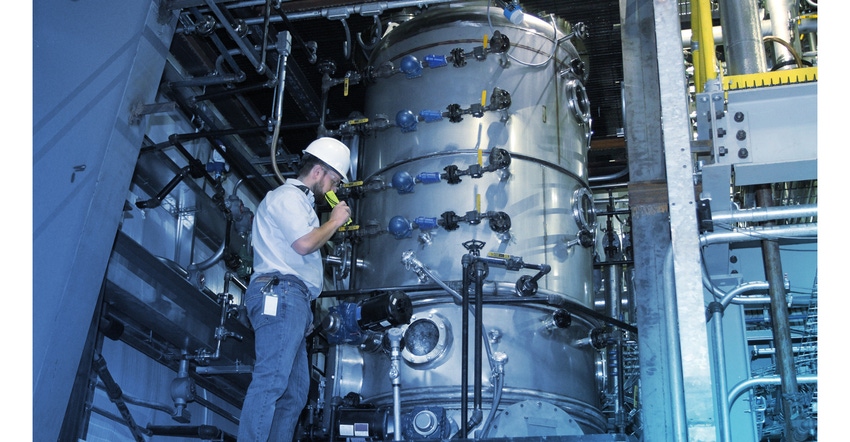

Crown Introduces Continuous Vacuum Desolventizer Stripper

Provides continuous indirect vacuum drying and desolventization

April 18, 2022

Crown introduces a new Vacuum Desolventizer Stripper (VDS) that provides continuous indirect vacuum drying and desolventization for temperature-sensitive products.

Continuous and scalable, the VDS minimizes product denaturization and discoloration, consumes less steam, and delivers full solvent recovery —allowing customers to achieve a high-quality, solvent-free product. It also offers a smaller footprint with the desolventizer and stripper contained in one compact unit.

“This new VDS technology builds on Crown’s protein technology expertise and comprehensive drying and desolventization solutions,” said Kris Knudson, president & general manager, Crown Global Companies. “Crown’s proven technology is used to prepare all types of oilseeds for flour, protein concentrates, and protein isolates, and with VDS customers can unlock even more new product innovations.”

In addition to oilseeds, Crown’s drying and desolventization technologies are used to help develop products across numerous specialty segments including plant-based proteins, hemp/CBD, food & beverage, nutraceuticals, botanicals, and pharmaceuticals, as well as specialty chemicals.

For new and existing products and processes, Crown helps customers determine their optimal drying and desolventization solution to maximize product yield and minimize process cost. With access to Crown’s Global Innovation Center and state-of-the-art pilot plant, customers can test the evaporation of water or solvent from raw inputs using Crown’s full range of drying and desolventization equipment in a confidential, real-world environment.

Crown Iron Works, Blaine, MN 651-639-8900 www.crowniron.com

About the Author(s)

You May Also Like