Sakuu Offers Early Access to Printing Battery Electrode Platform

Printing batteries on the platform with dry process technologies eliminates toxic solvents.

December 14, 2023

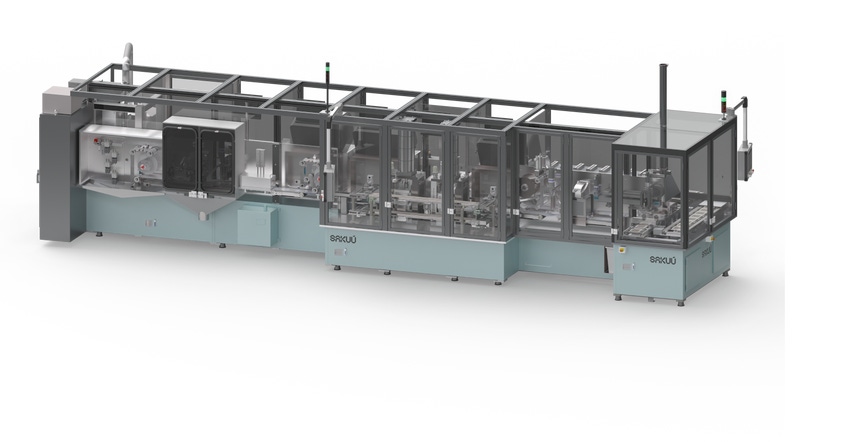

Sakuu, provider of equipment and technologies to the battery manufacturing industry, is offering early access to Kavian, the world’s first manufacturing solution to print battery electrodes. Early adopters are able to leverage the platform’s equipment, printable materials, electro-chemistry formulations, and process technology to develop the next generation of batteries in a completely dry process.

“Having experienced Sakuu’s technology firsthand, I am convinced the Kavian platform is revolutionizing battery production,” said Sandy Munro, CEO of Munro & Associates. “I am not receiving any payment to endorse the company. I simply see that Sakuu has achieved what others are still striving for. This positions Sakuu uniquely in advancing the field towards solid-state batteries.”

By printing batteries on the Kavian platform, OEMs can tap into cleaner energy sources while eliminating the need for troublesome solvents and drying mechanisms. Sakuu innovations help companies compete in a battery supply chain expected to reach $410 billion by 2030, according to a report by McKinsey & Co.

Printing batteries on the Kavian platform with dry-process technologies will:

Eliminate all toxic solvents and materials, including NMP and PTFEs

Cut factory floor space requirements up to 33%

Reduce utility costs up to 40%

Improve factory carbon footprints up to 40%

Electrodes printed by Kavian have been proven to achieve equivalent or better performance to today’s 30-year optimized processes with the added opportunity to customize battery cell chemistry, features, and design.

The Kavian platform fits seamlessly into today’s manufacturing lines, says the company. The platform is engineered to be material agnostic, supporting each manufacturer’s unique specifications, performance, and form factor needs, enabling OEMs to customize component dimensions and thickness from five to 200 microns.

Three areas of Kavian process stations include:

Dry Powder Printing: Dry powder is printed at desired thickness.

Powder Conditioning: The powder is conditioned to meet battery requirements.

Surface Inspection: At multiple points, the printed layer is inspected for quality control.

“After seven years of intense research and development, Sakuu has solved fundamental issues plaguing the battery industry,” said Robert Bagheri, founder and CEO of Sakuu. “Printing batteries, without solvents, finally gives manufacturers a chance to change how and where this critical industry can thrive. The foundational building-block approach to the Kavian platform is the key to unleashing innovation for next-generation batteries, including solid-state."

The Kavian platform is now available for go-to-market development opportunities, with expanded availability in late 2024.

About the Author(s)

You May Also Like