MIT Researchers Develop 3D Printing of Metallic Powder for AM

The nanowires powder was developed for additive manufacturing.

June 14, 2023

A key to many applications in aerospace and energy generation is to be able to withstand extreme conditions such as high temperatures and tensile stresses without failing.

A team of Massachusetts Institute of Technology (MIT)-led engineers reportedly found a simple way to strengthen Inconel 718 with ceramic nanowires to be used in metal powder bed fusion additive manufacturing processes.

The team at the MIT Materials Research Laboratory used 3D printing of a metallic powder strengthened with ceramic nanowires to improve other materials.

“There is always a significant need for the development of more capable materials for extreme environments. We believe that this method has great potential for other materials in the future,” said Ju Li, the Battelle Energy Alliance professor in Nuclear Engineering and a professor in MIT’s Department of Materials Science and Engineering.

How It Works

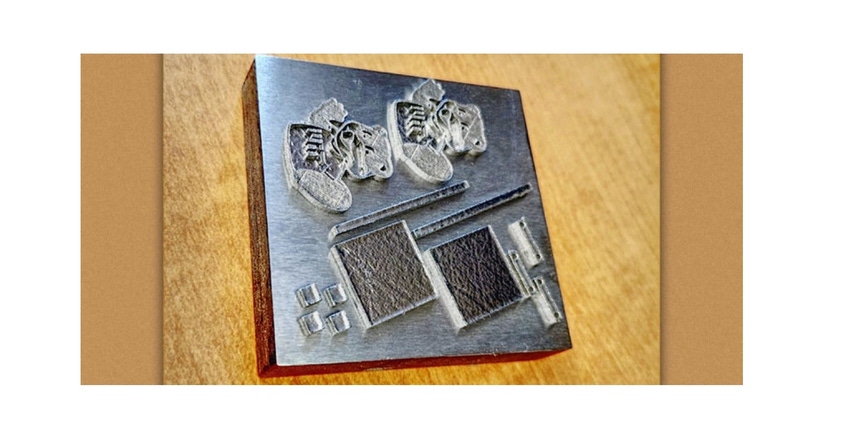

The team used Inconel 718, a “superalloy,” or metal capable of withstanding extreme conditions such as temperatures of 700 degrees Celsius (about 1,300 degrees Fahrenheit). They milled commercial Inconel 718 powders with a small amount of ceramic nanowires, resulting in “the homogeneous decoration of nano-ceramics on the surfaces of Inconel particles,” the team stated.

The resulting powder is then used to create parts via laser powder bed fusion, a form of 3D printing, which involves printing thin layers of powder that are each exposed to a laser that moves across the powder, melting it in a specific pattern.

Another layer of powder is spread on top, and the process repeats with the laser moving to melt the pattern for the new layer and bond it with the layer below. The overall process can produce complicated 3D parts.

The researchers found that parts made this way with this new powder have significantly less porosity and fewer cracks than parts made of Inconel 718 alone.

And that leads to significantly stronger parts that also have a number of other advantages. For example, they are more stretchable and have much better resistance to radiation and high-temperature loading.

As well, the process itself is not expensive because “it works with existing 3D printing machines. Just use our powder and you get much better performance,” said Li.

The work “could open a huge new space for alloy design” because the cooling rate of ultrathin 3D-printed layers of metal alloys is much faster than the rate for bulk parts created using conventional melt-solidification processes, Li said.

He added that as a result, “many of the rules on chemical composition that apply to bulk casting don’t seem to apply to this kind of 3D printing. So we have a much bigger composition space to explore for the base metal with ceramic additions.”

This work was supported by Eni S.p.A. through the MIT Energy Initiative, the National Science Foundation, and ARPA-E.

About the Author(s)

You May Also Like