Eliminating PFAS Contamination with Thermal Induction Heating

Using this method, researchers broke down PFAS left on water treatment filters in 20 seconds.

July 19, 2023

University of Missouri researchers came up with a new method using thermal induction heating to rapidly break down PFAS left on the surface of two solid materials — granular activated carbon and anion exchange resins — after the materials have been used to filter PFAS from municipal water systems.

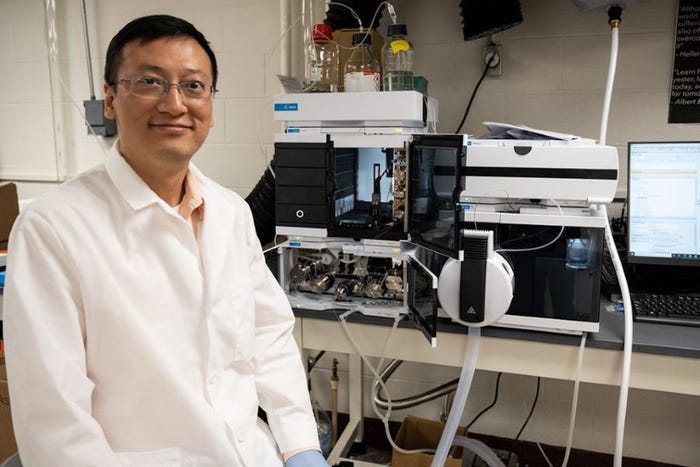

Dr. Feng “Frank” Xiao, associate professor in the Department of Civil and Environmental Engineering at the University of Missouri College of Engineering, and his colleagues have been working on thermal treatment for a while, which is likely the first treatment in the world used in this process.

The study, “Thermal phase transition and rapid degradation of forever chemicals (PFAS) in spent media using induction heating,” was published in American Chemical Society's journal, ACS ES&T Engineering.

“Since the group of chemicals known as PFAS generally resist degradation, they pose considerable challenges to established treatment processes, including the waste disposal practices for materials used as filters like granular activated carbon and anion exchange resins,” Xiao said.

PFAS can be filtered out of water using absorbents, but the disposal of used or “spent” absorbents creates issues of environmental contamination. The team’s goal is to clean the materials before they are properly disposed.

The method is based on the Joule heating effect, which uses the process of electromagnetic induction inside a metallic reactor. It produced 98% degradation of PFAS on the surface of absorbents like granular activated carbon and anion exchange resins after just 20 seconds, which makes this process highly energy efficient and faster than conventional methods.

There are drawbacks, however. If the temperature isn’t high enough, PFAS will form other products. These are created during this process — organic fluorinated species and hydrogen fluoride. While they are considered toxic to consume through breathing or ingestion, Xiao has a solution.

“If the gaseous organic fluorinated products are not degraded during induction heating, abatement treatment will be necessary to remove or degrade them,” Xiao said. “However, based on my previous studies, some of these products can be degradable by regular thermal approaches. Simultaneously, the generation of hydrogen fluoride is increased, which is desirable because it means greater mineralization, or decomposition, of PFAS. We’ve found hydrogen fluoride can be removed simply using clay or soil at moderate temperatures.”

Xiao said that organic compounds are harder to remove. “We need more information to do that. But I think we have some idea. And the results so far are promising to achieve 100% demineralization and achieve a not zero but a minimum formation of the organic byproducts.”

Xiao’s research group was the first in the world to demonstrate degradation of forever chemicals at temperatures as low as 150oC in three papers published between 2019 and 2021. Thermal treatment has now become one of the most promising technologies to completely degrade forever chemicals.

In another project, he demonstrated how to break down PFAS in soil by inserting extreme heat. In a paper published in 2022, Xiao found that heating soil temperatures to 500 degrees for just 30 minutes degraded 99% of all PFAS.

About the Author(s)

You May Also Like