January 26, 2024

Acerinox plans to invest 67 million euros in its high performance alloys division and introduces its new Excellence Plan.

VDM Metals, the Acerinox Group division and global leader in this sector, will increase sales by 15% due to the new commitment to higher value added products. Among the planned investments is an atomizer for the production of stainless steel and high-performance alloy powders for use in additive manufacturing. In tandem, Acerinox introduces Beyond Excellence, an ambitious and comprehensive operational excellence program for 2024 to 2026.

Both projects fall within the framework of Acerinox’s Strategic Plan and reinforce two of its pillars: Added Value, thanks to the new investments in VDM Metals; and Excellence, through the Beyond Excellence program. The projects will also have direct impact on the plan’s two other pillars: Sustainability and Financial Strength.

These investments will also strengthen integration by allowing the processing of high-performance alloys at the stainless steel manufacturing facilities at Campo de Gibraltar and increasing product range.

The projects include the expansion of three remelting furnaces, the upgrade of an annealing and pickling line, and a defect detection line for bars, to name a few.

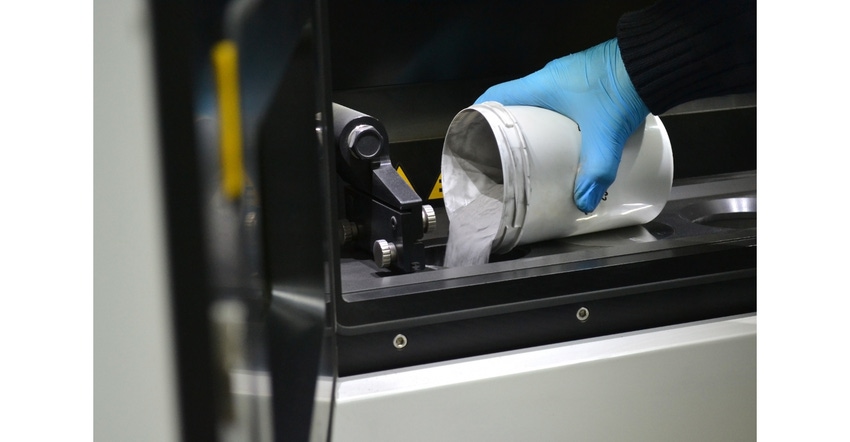

Among the approved projects is the installation of a second powder atomizer for additive manufacturing (3D printing). This investment will double the production capacity of this material, allowing growth in a market in which VDM Metals is already a highly valued supplier among customers. VDM will collaborate on this technology with the most prestigious equipment manufacturers.

The main objective of the Strategic Plan is to improve the Group's overall competitiveness through initiatives for continuous improvement that will be implemented at all factories between 2024 and 2026. These initiatives will be based on digital transformation, interdisciplinary collaboration, and a commitment to innovation.

The plan is built around six pillars (Decarbonization; Efficiency; Development of New Product Types; Productivity and Automization; Quality; and Customer Service and Purchasing), with specific objectives for each of these areas. It is set in motion with the following purposes:

Improve the company’s operational performance and competitiveness.

Achieve a recurring annual target of 100 million euros in EBITDA between 2024 and 2026.

Further a culture of continuous improvement and innovation throughout the organization, aligned with management by objectives.

To this end, the Group has identified new projects for 2024 that will focus on the following areas:

Improve quality and output in the production of high-value-added stainless steels.

Optimize the use of scrap metal as a main raw material.

Optimize mixes of raw materials.

Increase equipment productivity thanks to digitalization.

Use of predictive techniques to improve quality and maintenance.

Improve consumable and energy efficiency, which will result in reduced CO2 emissions.

About the Author(s)

You May Also Like