Reducing Energy Costs for Ventilation and Emission Control Systems

August 6, 2007

|

Figure 1: A side-draft hood |

The mathematics for properly designing ventilation and emissions control systems have been around for a long time, but studies of hundreds of systems show that many such systems waste energy while lacking the capacity to meet applicable codes and process objectives.

Operating costs of these systems is expensive. More than 40% of the energy consumed in most manufacturing plants is used to power fans, pumps, and ventilators. In some cases, the annual operating costs of a system may actually exceed the initial capital cost within two years of installation. Opportunities for improvement reside in the air-power equation.

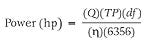

The power required to run an air-handling system is computed as follows:

1. Volumetric flow rate, Q (cfm).

2. Total pressure, TP (in. H2O)—resistance resulting from friction in ducts, hoods, and the ΔP of the control device, etc.

3. Density factor of the gas being collected, df.

4. Efficiency of the fan, η.

These factors are combined into the air-power equation:

Small reductions in the numerator can have a significant cost impact. For example, a typical 20,000-cfm baghouse requires 60 hp or more for operation. A volumetric flow rate reduction of 1000 cfm with an improved hood design or a reduction of 1 in. static pressure with an improved duct or baghouse system can save as much as $4000 per year.

|

Figure 2: Short-radius elbows and system effects |

However, there are always limits to system modifications. A given process may require a particular airflow rate or hooding arrangement that will dictatew air volume. Therefore, adjustments to system pressure and fan efficiency may be better places to effect power reductions.

System pressure is usually affected by two factors:

1. Hood and duct resistance as a function of velocities in the system and the inefficiencies of flow caused by poorly designed hoods, short radius elbows, branch entry angles greater than 45°, abrupt contractions, and elbows and other interferences at fan inlets and outlets (known as fan system effects).

2. Resistance across the emission control device. A baghouse that operates at a pressure drop of 8 in. H2O requires twice the power of a collector operating at 4 in. H2O. However, a lower-pressure-drop collector may not provide the capture efficiency of the baghouse with a higher pressure drop. Pressure drop in a baghouse can be lowered by adding filter area, but this approach requires a larger housing. More important, baghouses often perform best at high pressure drops. The key is to minimize pressure drop while meeting emissions requirements. Excess static pressure just wastes power.

The following tips indicate how to find the narrow range of safe and efficient operation.

Minimizing Flow. Systems directly connected to a process source are inherently volume-limited, whereas systems that capture emissions with enclosures or hoods need to be optimized during the design process. Total enclosure of an emissions source minimizes airflow and worker exposure. However, such enclosures can restrict visual observation of the process and hinder maintenance access.

Hoods that cannot be designed for total enclosure should be located as close to the source as possible. A side-draft hood (Figure 1) located twice the distance from the source can require as much as four times the exhaust volumetric flow rate as a total enclosure. Capture hoods for high-velocity emissions (from grinding, sawing, etc.) must be located so that the opening is in the direct path of the dust, fume, or mist. The American Conference of Governmental Industrial Hygienists publication Industrial Ventilation—A Manual of Recommended Practice provides guidelines for good design of hoods, duct, and similar equipment.

|

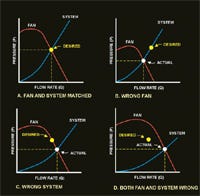

Figure 3: Matching the fan to the system is critical. |

Since other factors such as explosive limits for the gas being collected, moisture content (dew point), and heat content may influence the air volumetric flow rate requirements, there may be limits to optimization.

Minimizing Pressure. Lowering pressure offers greater opportunities for reducing energy costs than reducing flow. A system with good airflow characteristics in which duct velocities and sizes have been optimized, coupled with the proper control device, pressure monitors, and variable-frequency drives, can help manage system pressure. Most baghouses or other collection devices have varying pressure drops over the life of the system. While bags are generally more efficient at higher pressure drops, they use more energy. Scrubbers, oxidizers, and electrostatic precipitators tend to operate at more constant resistance. A good pressure-monitoring system that controls the system volumetric flow rate can save thousands of dollars every year for even medium-sized systems. As variable-frequency drives become less expensive, they are appearing in many installations, especially systems of over 10,000 cfm.

Duct inefficiencies and fan system effects (elbows at inlets and outlets, etc.) increase static pressure and operating costs during the life of the system. Figure 2 shows short-radius elbows and system effects that result in $6500 per year in wasted power.

|

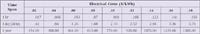

Electrical costs for ventilation system fan, per horsepower |

Controlling Density. Temperature, moisture, molecular weight, elevation, and the absolute pressure in the duct or vessel affect the density of the transporting gas. A density change may affect the system’s hardware requirements. Evaporative cooling, for example, reduces volume, but the higher-density air requires more power. However, this increased power consumption may be more than offset by reduced costs for smaller ducts, control devices, and fans, which lower the value of the volumetric flow rate in the equation. Cooler temperatures may also allow the use of less-expensive collectors, fans, and peripheral devices.

Fan Efficiency. The design of the fan and its blade type can greatly affect efficiency and power requirements. Laboratory-measured peak fan efficiency may not be the most stable point of operation. If peak efficiency coincides with the peak of the pressure curve, operational problems may arise as the volumetric flow rate varies with small changes in system pressure. The designer must consider both curves when selecting the best fan and operating point to optimize reliability and power use. Fan type may dictate proper selection. However, airfoil wheels, while more efficient, may not be a good choice when handling particulate-laden air.

The key to any design is proper fan selection. Figure 3 illustrates the importance of matching the fan to the system. The three improper configurations waste power and cause unsatisfactory system performance.

Table 1 shows the electrical costs for a ventilation system fan per horsepower. If a system runs 24 hours a day with a 50-hp motor and the plant operates 200 days per year at an electrical cost of $0.08/kWh, annual costs would be 50 hp × $1.68/24-h day × 200 days/yr = $16,800/yr. One-year costs in the table are based on 8760 hours of operation (365 days, 24 hours per day). In the above example, the same 50-hp motor run continuously for 365 days would have an annual operating cost of 50 hp × $613/hp = $30,650.

Conclusion

The power equation identifies four main areas that affect energy consumption: volumetric flow rate, pressure, density, and fan efficiency. The challenge for industry is to operate in the narrow functional range that guarantees system effectiveness with minimum energy consumption. Attention to the air-power equation can help meet those goals.

Gerry Lanham, P.E., is president of KBD/Technic Inc. (Cincinnati), which specializes in industrial ventilation engineering. He has more than 41 years of experience in the design and installation of dust control and industrial ventilation systems. For more information, call 513-351-6200 or visit www.kbd-technic.com.

In addition to energy… Before using the air-power equation, teams planning to initiate new projects or system alterations should consider the following good design goals: 1. Protecting worker and public health by meeting local and national standards for in-plant air and exhaust. |

About the Author(s)

You May Also Like