Increasing Food Processing Safety with Powders and Bulk Solids

Morgan Bailey-Burford, Cablevey Conveyors, answers key questions about how food processors can mitigate risk and prevent many safety issues by utilizing closed conveyor systems designed with sanitation in mind.

January 23, 2023

In the food industry, many producers who process, handle, and package dry particulates are challenged to reduce the risk of recall due to potential contamination, which can cause severe losses and reputational damage if it occurs.

Morgan Bailey-Burford, communication specialist at Cablevey Conveyors, answers key questions about how food processors can mitigate risk and prevent many safety issues by utilizing closed conveyor systems designed with sanitation in mind.

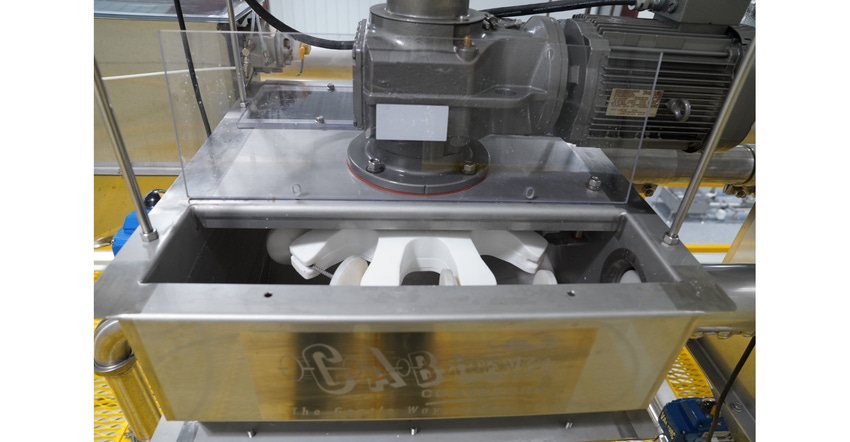

Cablevey Conveyors is a mechanical conveyor manufacturer that serves the global coffee, nut, pet food, and specialty food markets. The company has designed, engineered, and serviced enclosed cable and disc tube conveyors for 50 years in more than 66 countries.

Q: In terms of food safety for dry particulates, what is the role of the Preventive Controls Rule and conveyors for reducing the risk of recalls due to contamination?

A: Given the increasing number of outbreaks and recalls traced to post-processing contamination of foods, it is no surprise that the Preventive Controls Rule requires manufacturers to implement a food safety plan with the goal of preventing sanitation deficiencies. The rule covers sanitation practices for food-contact surfaces, preventing microbial and chemical cross-contamination, and monitoring potential environmental pathogens for critical equipment like conveyors.

As a result, quality assurance teams are paying more attention to the type and design of conveyance systems used to help meet food safety standards. This includes identifying potential harborage points where debris and pathogens can collect, as well as implementing best practices to save on costs to clean equipment, perform regular testing, and maintain the environment.

With conveyors, ideally there should be minimal harborage points, they should protect products from the environment, and be easy to clean. Given the risks of contamination, the potential for recalls, and the additional costs associated with regular cleaning and testing, it’s advisable to select a conveyor that eliminates many of the potential risk factors.

Q: For food safety with dry particulates, how do open and closed conveyors compare?

A: In the food processing industry, open conveyor systems like bucket elevators and belt conveyors can be more vulnerable to contamination. With open systems, products can be exposed to pathogens, contaminants, or moisture in the surrounding environment. Product can also spill onto the plant floor and make its way into drains. Consequently, processors that use such conveyors must maintain strict environmental controls including constant swabbing, testing, and quality assurance.

Closed conveyor systems, on the other hand, effectively seal off products from the outside environment. Even then, it is still necessary to control the environment. Although there are several types of closed systems, one popular example when conveying high-value foods is tubular drag cable conveyors. These systems gently move products that are prone to breaking or crumbling through a sealed tube using a coated, flexible stainless steel drag cable pulled through on a loop. Solid circular discs (flights) are attached to the cable, which push the product through the tube without using air. The coated cable ensures that no debris accumulates within the strands of the cable, as the cable is totally sealed.

A closed conveyor provides a controlled environment that reduces the risk of exposure to contaminants and pathogens from outside the system when properly maintained. Because it is closed, it is less susceptible to aerosols and over spray from adjacent lines.

Q: How effectively do closed conveyors like tubular cable conveyors maintain cleanliness?

A: When a third-party food sanitation expert conducted trials and verification testing, he found that tubular cable conveyors maintain greater repeatability of cleanliness than open systems over a longer period of time, due to the controlled environment within the enclosure.

Additionally, closed conveyors significantly reduce potential harborage points for contamination. Tubular drag cable conveyors are very simple in construction, without standard joints, threaded bolts, and plastic-to-metal connections.

Q: Do closed conveyors have other sanitation advantages?

A: Yes, closed conveyors like tubular cable conveyors also enable a “wet cleaning” process without wetting the surrounding areas, in which the systems can be quickly and effectively flooded with water and sanitized without disassembly.

While not all food processing materials are suited to wet cleaning, such as hygroscopic materials that readily absorb and retain moisture, the process minimizes potential contamination for other types of food. The wet cleaning procedure begins with a water rinse followed by foaming agent, a sanitizing rinse, and a final water rinse. Once the system is thoroughly flushed out, drying is achieved by attaching urethane wipers to the tubular conveyor’s discs, which act like a “squeegee” to remove any residual water.

Within the tubular system, all wash factors can be repeatably controlled – water chemistry, temperature, physical action, and time – so every surface is equally cleaned. Clear tubes are also available that offer the additional benefit of visual inspection or verification.

Since a complete and thorough cleaning can be accomplished without disassembly of the system, the entire process only takes 20-90 minutes, depending upon the layout, product, and desired level of cleanliness. This can substantially reduce disruptions and downtime during production changeovers and eliminate the need for additional dedicated conveyor lines. Regular cleaning can be automated through the plant’s distributed control system.

Another benefit is the repeatability and verification of surfaces cleaned and the ease of maintaining them. You can do verifications against cleanliness and hold the cleanliness over a greater period of time.

Q: What else can a food processor do to help ensure that a conveyor will meet their sanitation requirements?

A: A food processor can contact an enclosed conveyor system manufacturer to request that their quality assurance team may perform tests prior to purchase. Then the team can visit the OEM’s test lab to run product and conduct swab tests before and after wet cleaning.

Q: Overall, how can food processors benefit from utilizing enclosed conveyors?

A: Preventing safety issues is a critical goal for processors who seek to protect their customers’ and their own bottom lines from recalls and the high costs associated with them. Using enclosed conveyors that are capable of automated wet cleaning eliminates the need for manual cleaning, thus minimizing risk and decreasing sanitation deficiencies.

For more information, call 641-673-8451, email [email protected], or visit cablevey.com.

About the Author(s)

You May Also Like