Automated Grinding System for Seed Facility

April 23, 2018

It isn’t unusual, in fact it is commonplace, for seed to be treated with pesticide, fertilizer, and other things that will aid in the growth of the plant and its harvest yield. Some treatments require processing of raw ingredients from a granular material in specific proportions that are then batched and attached to the seed downstream in the process. This article summarizes one such application.

There are two granular raw materials. Both are dosed into a fine grinding machine at specific rates and proportions. Included in the process control and automation system for this grinding and classifying system:

* Two bulk bag unloading systems with surge bin and loss-in-weight feeder

* One flexible screw conveyor with surge hopper

* One fine grinder

* One existing filter receiver

* One existing silo

* One HMI/PLC control panel

* One VFD/starter control panel

While it is typical that the automation vendor, Sterling Systems & Controls Inc. in this case, provides the mechanical equipment on systems applications, in this application only the design and manufacture of the two automation system control panels (the HMI/PLC control panel and the VFD/starter control panel) was provided. Sterling Systems is a UL listed control panel manufacturer certified for the U.S. and Canada.

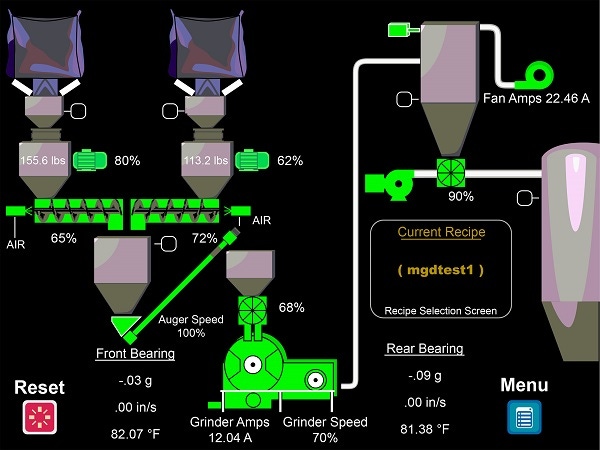

HMI/PLC Control Panel & System Operation

It is important that the automation supplier understand the process, not just the control technology. In this application Sterling Systems worked with the supplier of the mechanical equipment, Prater Industries, to make sure the mechanical equipment would do the job required by the seed processing customer. Sterling Systems designed and manufactured the HMI/PLC control panel as required, customized to do the specific job that was needed. The main operator interface for this system is via an Allen Bradley PanelView 10-in. industrial touchscreen HMI, and an Allen Bradley PLC, mounted in an enclosure running a custom designed process control application by the automation supplier. The HMI/PLC control panel and PanelView HMI provide all control and equipment status information necessary to run the automated process control system.

Each piece of equipment has a virtual M-O-A switch in the HMI. Placing all switches in the M (manual) mode allows the system to be operated manually. All switches must be in the A (automatic) for automated operation. The operator will use the HMI to select one of five previously stored sets of parameters to run. Each set of stored parameters contains the following data points:

· RM#1 speed setpoint (%)

· RM#1 agitator speed setpoint (%)

· RM#2 speed setpoint (%)

· RM#2 agitator speed setpoint (%)

· target fine grinder load (amps)

· fine grinder high amps (amps)

· fine grinder low amps (amps)

· filter receiver discharge airlock speed setpoint (%)

· filter receiver fan high amps (amps)

· filter receiver fan low amps (amps)

· fine grinder speed (%)

· fine grinder feeder airlock speed (%)

After placing all switches in automatic, the operator will then press the start button on the panel. The start button will flash during startup. The system will verify that the material level in the existing silo level is not indicating a high level condition in the silo. If a high level condition is present, the system will generate an alarm and will not start. Next, the silo blower will be started and confirmed running. While the silo blower is running, the system will monitor for silo blower low pressure. If the silo blower low pressure sensor indicates a low pressure for longer than a programmable time, the system will display a Low Pressure alert on the HMI screen.

The above partially illustrates the customized process control system designed and implemented by Sterling Systems & Controls, Inc. It continues with complete automatic operation of all the process equipment required by the seed processing customer. This includes monitoring and controlling all items listed above, in order to produce the necessary finely ground and blended raw materials for further use in producing finished and coated seed. The HMI/PLC panel also includes all the weight instruments for the two loss-in-weight feeders within the bulk bag unloading systems.

VFD/Starter Control Panel

The VFD/starter panel encloses the electrical controls required to operate all of the process equipment items. This is a 480VAC panel and includes: a control transformer, VFDs and motor starters for the bag unloaders, feeders, a fine grinder, all airlocks, and other process equipment items within the overall system.

While not included in this specific system, the company can interface with a local business system and can also provide a supervisory remote control application if desired. This is called WebCentral supervisory control. WebCentral is a software package that allows corporate users to access the database of a Sterling Systems process control system, such as the seed process equipment discussed. This can be used to enter and manage all configurable items remotely using a PC’s web browser.

Sterling Systems & Controls Inc., Sterling, IL, has over 40 years of experience providing efficient process automation solutions, including batching systems, micro/minor ingredient systems, bulk weighing systems, bulk bag unloading system, and plant process automation. For more information, call 815-625-0852 or visit www.sterlingcontrols.com.

For related articles, news, and equipment reviews, visit our Instrumentation & Control Equipment Zone

Click here for a List of Instrumentation & Control Equipment Manufacturers

You May Also Like