Combustible Dust: DHA and Other Methods for Prevention

If your dust is combustible, you need to be concerned with the risk.

September 14, 2020

Phil Rankey, lead application engineer, Parker Hannifin Corp.

If your dust is combustible, you need to be concerned with the risk. According to a report published by Dust Safety Science¹, 34 dust explosions and 115 fires were logged globally in just the first six months of 2019. The incidents during this period resulted in 13 deaths and 66 injuries.

Could any of these dust explosions or fires have been prevented had a dust hazard analysis (DHA) been conducted? Proper dust explosion protection and housekeeping are critical, but new safeguards need to be taken. According to NFPA 652, you should have a DHA complete by now for any dust or powder that is collected. According to Dust Safety Science, in the past four years, the US averaged 33 dust explosions, 30 injuries, and three fatalities per year. These fires and explosions resulted in over $1 million in property loss.

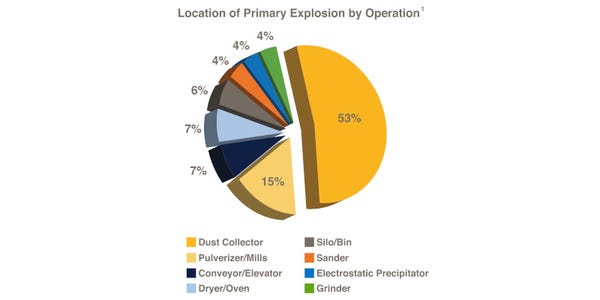

Dust collectors are being scrutinized because 53% of all primary dust explosions happen within dust collectors, which can result in secondary explosions in or around the facility. Explosions are devastating as are all safety incidents when they can be avoided. Know your options.

Recommended Approach for Prevention

Do You Need Explosion Protection?

1) Analyze Your Dust

a. Acquire all information including the SDS or other safety documentation about the dust and the process

b. Determine whether the collected dust(s) are combustible or explosive by having it tested by an accredited lab per ASME standards

c. Determine the necessary combustibility and explosivity characteristics of the dust such as Kst, Pmax, MIE, and MEC values

d. If tests reveal potential hazards, review with experts on dust control solutions for how to safely and effectively handle the collected dust

2) Design the Right Dust Collection System

a. Design capture devices to control contaminants preventing fugitive dust accumulation

b. Duct design should effectively transport dust from capture point to dust collector

c. Equipment must be capable of successfully collecting contaminants

d. Locate the dust collection system outdoors if possible and isolate any potential explosion

e. Configure the system to deflagrate or suppress any potential explosion

f. Minimize possible ignition sources such as sparks or static electricity

3) Correct Operation and Maintenance

a. Document proper system performance and regularly inspect your dust collection systems

b. Perform regular housekeeping inspections looking for accumulating dusts and ensure the safety devices are operating correctly

c. Accurate label all hazardous dusts or process materials

d. Provide training for your employees on proper operation of dust collections and associated hazards of combustible dust handling

e. Develop an emergency action plan for your facility

Dust Hazard Analysis (DHA)

The recommended approach for explosion and fire prevention can be implemented with a dust hazard analysis (DHA).³ What is a DHA? It’s a systematic review of all processes. The review determines where a fire or explosion could occur. It looks at the causes and what the consequences are and determines if existing safeguards are enough. If they aren’t, the DHA will include a recommendation of what safeguards are required.

You need to make sure that the review is completed by a “qualified person.” Someone with the experience and credentials that can properly identify potential abnormal conditions. You can expect that they will look at all processes that create dusts.

The analysis will include how fires could move between processes, determine what is a normal, abnormal, and what an upset condition would look like. They will itemize all processes and equipment including bins, tanks, silos, hammer mills, pulverizers, grinders, welders, dust collectors (wet and dry) conveyors, screw augers, bucket elevators, sifters, and screens, to name a few.

The DHA will identify all materials that create dust and what the hazard could be, review all SDS sheets, and review books and online material for information on the dust. The analyst will determine if dust requires testing by a lab and help you develop a plan for dust control, housekeeping, training, and preventive maintenance.

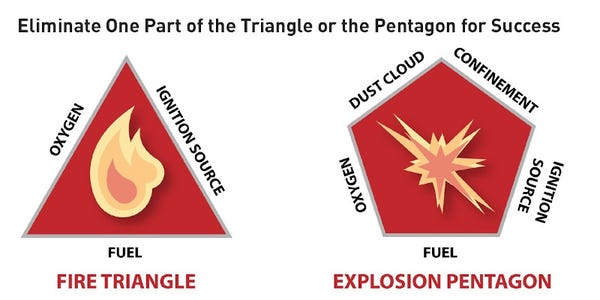

If just one part of the fire triangle or the explosion pentagon can be removed, the hazard is eliminated. Both figures have oxygen, ignition source, and fuel. Oxygen is pretty much impossible to eliminate, so we will concentrate on the other two, ignition source, and fuel.

Ignition source can be managed by coordinating the following:

• Electrically powered cleaning devices such as vacuum cleaners. Electrical equipment must be approved for the hazard classification

• Ignition control programs such as grounding and bonding for dissipating any electrostatic charge that could be generated while transporting the dust through ductwork

• A hot work permit program

• No smoking or specified smoking areas

• Properly designed duct systems, collectors, and dust-producing machinery that are bonded and grounded to minimize accumulation of static electricity

• Facility selects and uses industrial trucks that are approved for the combustible dust locations.

Fuel (and dust cloud) control measures:

• Dust containing systems are designed in a manner that fugitive dusts are not allowed to accumulate in the work area.

• The facility has a housekeeping program with regular cleaning frequencies established for floors and horizontal surfaces, such as ducts, pipes, hoods, ledges, and beams to minimize dust accumulations within operating areas of the facility.

• Working surfaces designed to minimize dust accumulation and facilitate cleaning

• By good housekeeping, a secondary explosion could be prevented. These are typically what devastates the facility. The first explosion shakes all the accumulated dust off the pipes, rafters, and horizontal surfaces and if these are not kept clean, it can trigger the secondary explosion which is what usually results in injuries and deaths

All decisions of what is required come down to the “authority having jurisdiction” (AHJ). This person could be the local fire marshal, OSHA inspector, or the insurance underwriter to name a few. There should be someone at your facility that works with the AHJ on preventative measures and the protection plan designed to your facility. The bottom line is that the owner of the facility is responsible for all local, state, and federal codes, standards, laws, and regulations for combustible dusts.

If you haven’t completed your DHA as required by NFPA 652 and you need help finding an analyst, contact a specialists for assistance through [email protected] or www.parker.com/airquality.

Phil Rankey is lead application engineer, Parker Hannifin Corp., Overland Park, KS. For more information, call 913-374-3162 parker.com or visit www.parker.com.

Sources

1 dustsafetyscience.com/dust-safety-science-podcast/, August 24, 2020

2 www.dustafetyscience.com, August 24, 2020

3 www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=652, August 2020

You May Also Like