How to Select a Dust Collection System That Ensures Safe Air Quality

Consulting with an industrial dust collection professional is the best way to ensure a facility is using the most effective dust management system.

June 9, 2023

Josh Delson, director of OEM and segment sales, Camfil Air Pollution Control

Companies have a responsibility to provide a safe work environment for their employees, including maintaining good air quality to protect the health and safety of workers. In its General Duty Clause, the Occupational Safety and Health Administration (OSHA) requires employers to provide a workplace that is free from hazards that could harm employees.1 More specifically, OSHA has established permissible exposure limits (PELs) for hundreds of dusts—from “nuisance” dust to toxic airborne particles—to protect employees from exposure to these contaminants.2

Facilities that process, manufacture, or use powders, sands, silica, and other dry materials create dust emissions that affect air quality. These emissions come from various operations, including blending, crushing, mixing, sanding, woodworking, cutting, pelletizing, transporting, and more.

Dust particles can be harmful to the health of workers who breathe or ingest them. They can also cause skin irritation and allergic reactions. In worst cases, dust particles can contribute to the development of lung diseases like asthma, pulmonary fibrosis, and even lung cancer. In fact, dust is the leading cause of poor indoor air quality, which can lead to health problems and combustible dust incidents. Dust can also contaminate products and damage manufacturing equipment.3

Finding an Industrial Dust Mitigation Solution

While ventilation systems are commonly used to improve air circulation in manufacturing facilities, they may not be sufficient to remove small airborne dust particles that contain toxic elements. Dust collection systems are specifically designed to capture and filter fine dust particles from the air in manufacturing plants, processing facilities, and small shops in various industries.

Unlike vacuum systems and housekeeping dust systems that perform precision cleaning in specific areas, dust collectors provide larger-scale filtration for facilities or process zones.

Because various types of dust collection systems are available, it is important to factor facility size, process dust composition, exhaust conditions, compliance rules, and applications when determining the most effective solution.

Dust collection systems most frequently used for industrial applications include:

Cartridge dust collectors

Baghouses

Wet scrubbers

Portable dust collectors

Understanding the differences of each type of collector in relation to the specific operation is key to choosing the right system.

Cartridge Dust Collectors for High-Capacity, General-Purpose Applications

Cartridge dust collectors are ideal for most industrial dust applications because they draw in high volumes of dust-laden air from the processing area, remove the dust by capturing it in cartridge-style filters, then return clean air to either the processing area or outside the facility. When the filters become loaded with dust, the collector automatically cleans them using a blast of compressed air, sending the dust into a hopper below for disposal. These high-capacity collectors can be used to mitigate dust and fumes during manufacturing and processing operations.

If cartridge dust collectors are determined to be the best solution, the next decision is what type of filter media to use. Base filter media is generally a nonwoven fabric that is often coated with chemicals to provide properties such as flame retardance, anti-stick, conduction, and static dissipation. However, if the process dust is combustible or explosive, facility operators must have it professionally analyzed to determine the safest filter media for the application.

Another factor to consider is the fabrication technology used to fold the media into the cartridge. When the pleats are wide to expose them to the airflow and uniform across the entire media, they will collect more dust and then release it more readily during pulse cleaning.

Because cartridge dust collectors are so versatile, they can be used for operations including:

Powder coating

Woodworking

Solid dose pharmaceutical manufacturing

Food manufacturing and processing

Paper and metal packaging materials manufacturing

Chemical processing

Grain, seed, and feed processing

Welding, laser, or plasma cutting

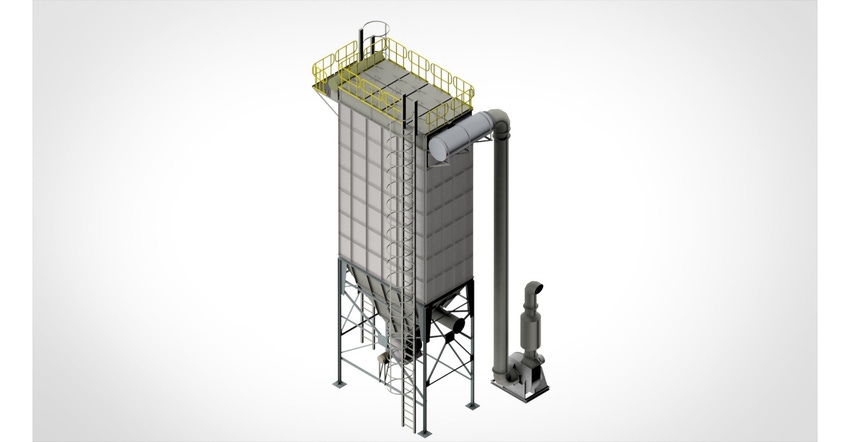

Baghouses for High Volumes of Dust-Laden Air

Baghouses--also known as bag filters or fabric filters--operate similarly to cartridge dust collectors, but they can handle higher volumes of particulate-laden air. These systems use multiple fabric bags, rather than cartridges, to filter dust particulates from process air.

During operation, air is drawn into the bottom of the unit, then a large fan forces the air through the long, cylindrical bags. The dust collects on the exterior surface of the bags. Sharp bursts of compressed air then cause particles to drop into a hopper. The filtered air can either be recirculated or vented outside, depending on the application and regulatory requirements.

Baghouses are capable of handling greater volumes of dust-laden air, making them ideal for high-volume, heavy-dust-loading applications and high temperatures. They can also capture larger-sized dust particles of up to 5 microns. While offering more capacity, these dust collectors have a large footprint and require more installation space.

Baghouses are ideal for industrial applications that require higher volumes of dust filtration on a regular basis, such as:

Lumber milling

Woodworking

Cement manufacturing

Glass and ceramic manufacturing

Applications with a high volume of dust and high cubic feet per minute (airflow)

Dust contaminated with oil and moisture

Processes involving sticky or abrasive materials

Wet Scrubbers for Combustible and Flammable Dust

Wet scrubbers--also known as air scrubbers--are a good choice for applications involving explosive or flammable materials or where the slurry consisting of liquid and collected dust particles can be reused or repurposed.

Compact wet scrubbers send air and dust through rough filtration before skimming it over the surface of water or scrubbing liquid. A portion of this liquid flows through a vortex zone within the unit, which creates turbulence that atomizes the liquid into fine droplets. These droplets mix with the dust-laden air stream and are then removed by centrifugal force. These compact scrubbers are useful for removing sticky dust.

Larger wet scrubbers are used for applications with higher dust loading. These units inject water into an inlet via a pump, generating high velocities that create contact surfaces with the scrubbing liquid. The contaminated air stream and scrubbing liquid are mixed, and the particle-laden droplets are separated from the airstream by centrifugal force.

Wet scrubbers are the best choice for applications involving:

Combustible dust

Wet or sticky dust

Humid air conditions

Portable Dust Collectors for Small-Scale Jobs

Portable dust collectors have a long collection arm and hood that collect dust and fumes at the source. The dust travels through the arm and passes through a cartridge filter that removes the particulates. When the filters need cleaning, a shot of compressed air directed through the filter releases dust into a tray for removal.

Manufacturers can use portable dust collectors as plug-and-play single units in multiple areas throughout a plant where they are most needed. They can be positioned to capture dust from specific locations. When used in conjunction with a larger dust collection system, they help extract any fugitive dust from the areas. However, unlike wet scrubbers, portable dust collectors are not suitable for explosive dust, nor should they be used to remove solvent fumes.

Portable dust collectors are beneficial for:

Small shops that do not require a large dust collection system

Welding shops

Working in tandem with a larger dust collection system in areas with heavy dust loads

Isolated jobs not located near a larger dust collection system

Auxiliary Systems for Cartridge Dust Collectors

When selecting a dust collector, facilities must consider the entire system including auxiliary equipment to ensure effective capture and removal of hazardous and nuisance dust from different environments. Here are a few important points to consider for a properly designed and installed dust collection system:

Explosion protection: When there is a potential for a combustible dust explosion within the dust collection system, it is important to equip the collector with explosion protection devices. Explosion venting, flameless vents, explosion isolation dampers, and integrated safety monitoring filters come together to improve the safety of the dust collector system.

Hoods: For applications that generate a significant amount of dust or high-hazard dusts, source capturing using pick-up hoods at production stations will pull airborne particulates directly into the dust collector before most of the particulates are released into the air. The hood must be properly designed to accommodate a capture velocity that is strong enough to overcome opposing air currents and transport the contaminant to the hood.

Ductwork: The system moves airborne particulates through ducts to reach the collector. If the process produces heavy dust, make sure the conveyance velocities are high enough to keep the particles suspended in the air while they are moving through the ductwork to the dust collector. If the velocities are too low, the particles can drop within the ducts or plug them. However, conveyance velocities that are too high cause the system to use more energy than needed to move the dust.

Fans: To achieve the system’s required airflow and static pressure/energy, fans must be properly sized. Oversized fans pull too much air into the collector, which can shorten filter life and increase energy costs. Undersized fans can reduce conveyance velocities in the ducts, causing dust to accumulate in the ductwork.

Compressed air system: Maintain a high enough air pressure. The pulse cleaning system cannot clean the filters properly if the pressure is too low.

Summary

Consulting with an industrial dust collection professional is the best way to ensure a facility is using the most effective dust management system. A properly configured dust mitigation program designed specifically for manufacturing or production operations will filter hazardous dust and fumes and render bulk processing facilities safer and healthier.

Josh Delson is director of OEM and segment sales for Camfil Air Pollution Control, manufacturer of dust and fume collection equipment for challenging industrial applications. For more information, call 800-479-6801, email [email protected], or visit camfilapc.com.

References

1 OSHA, OSH Act of 1970, Sec. 5. Duties, https://www.osha.gov/laws-regs/oshact/section5-duties

2 OSHA, Permissible Exposure Limits – Annotated Tables, https://www.osha.gov/annotated-pels

3 Ask the Expert: Hazardous Dusts, EHS Daily Advisor, https://ehsdailyadvisor.blr.com/2023/04/ask-the-expert-hazardous-dusts

You May Also Like