How to Get the Most Out of a Bulk Solids Rotary Dryer

Consider the following to get the most out of your bulk solids dryer.

November 12, 2021

Shane Le Capitaine, process sales engineer, FEECO International

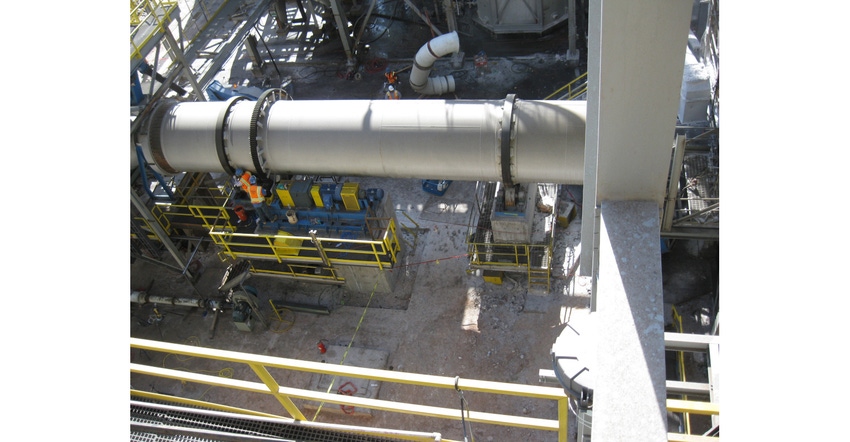

Rotary dryers have become an indispensable tool in the bulk solids arena, giving producers control over moisture content in feedstock, intermediary materials, and finished products. These industrial drying systems have become the backbone of many operations, from processing ore in the beneficiation process, to bringing a fertilizer product to market, and so much more.

Rotary dryers are highly customizable, offering significant opportunity to improve dryer efficiency and product quality by tailoring the unit to its intended application, whether that unit is new or already in operation. Consider the following to get the most out of your bulk solids dryer.

Optimize the Feedstock

While rotary dryers are recognized as industrial workhorses capable of accepting a range of materials, feedstock conditions can still have a major impact on dryer performance and the quality of product exiting the unit. For this reason, plant managers should carefully evaluate their feedstock in terms of uniformity and moisture content to ensure maximum performance and product quality.

Uniformity

Rotary dryers are often a favored approach to drying bulk solids because of their tolerance for small changes in feedstock and even feed rate of the incoming material. However, the best results are still achieved by keeping feedstock as consistent as possible: the more uniform the material coming into the dryer, the more uniform the material exiting the dryer. A non-uniform feedstock often results in inefficient drying, with some product being over-dried, while other product is under-dried.

The most important characteristics of uniformity when drying bulk solids in a rotary dryer are the moisture content and particle size distribution. For this reason, some operations may benefit from pre-treating their material feedstock to achieve a higher level of uniformity in these two aspects. This might include pre-drying the material, a particle size reduction step, or even the incorporation of a back-mixing step in which dried product is mixed with the feedstock to reduce the overall deviation in moisture content.

Moisture Content

Just because a rotary dryer can process a material doesn’t mean it can do so efficiently. In some cases, the starting moisture content of the feedstock may not be ideal for the dryer, which could result in the material sticking to the dryer and causing a host of other problems.

In general, materials with a moisture content higher than 30% may require a pre-drying step in order to optimize the material for better processing in the rotary dryer. Again, this could mean the incorporation of a back-mixing step or the inclusion of natural drying, dewatering, or other means of moisture reduction.

Customize the Dryer Design to the Process Requirements

The best-performing rotary dryers have one thing in common: they were designed around the unique requirements of their specified application. This requires evaluating both the material specifications (inlet and outlet), as well as the processing environment.

Various material characteristics and environmental aspects can factor into dryer performance. In terms of material characteristics, qualities such as the material’s specific heat, bulk density, heat transfer properties, and chemical composition can influence how the material will behave in the dryer, and subsequently, how the dryer will need to be designed to work with those characteristics. Similarly, environmental factors such as ambient air temperature, humidity, and plant elevation can also potentially impact the dryer design.

Several modifications can be made to optimize the dryer design to best work with the material and processing environment. This includes:

Customized Flight Design & Pattern

The flights, or material lifters, are one of the most influential aspects of a rotary dryer in terms of performance. Flights are available in a range of designs - single bend, double bend, straight, and even custom formations.

The design of a flight should work with the characteristics of the material to create the optimal “curtain,” or cascade of material across the drum’s interior diameter, as this promotes maximum heat transfer.

In addition to the flight design, flight pattern can also be customized to promote optimal heat transfer, whether that is through staggering flights, including advancing flights (spiral flights that assist in moving material away from the inlet and into the processing zone) or even a lack of flights for a portion of the dryer (referred to as a bald section).

Advancing (spiral) flights, along with two other flight designs, are employed in this dryer to maximize heat transfer between the material and products of combustion

The Addition of a Combustion Chamber

The addition of a combustion chamber can offer several benefits in some settings. While the primary goal of a combustion chamber is to prevent the material from coming into direct contact with the flame (thereby preserving product integrity and reducing emissions such as CO), it can also improve efficiency. This is because a combustion chamber enhances the ability to control the temperature of the process gas entering the dryer, and also promotes more uniform heating of the material.

The lack of contact with the flame is generally only considered a benefit for heat-sensitive materials, but it can also reduce the amount of attrition a product experiences.

Efficiency is also improved because dilution air can be incorporated into the combustion reaction, which promotes a more complete combustion of the fuel, while also offering an opportunity to utilize recovered waste heat from elsewhere in the plant.

Combustion chamber (at right) on a FEECO rotary dryer

Rotary Drum Size

Rotary drum size is one of the primary contributors to the overall cost of a rotary dryer. And while in some cases the size of the drum may be non-negotiable, in other cases, there can be some flexibility. Where possible, FEECO recommends increasing the air flow velocity to allow for a smaller-sized drum to be used. By incorporating an oversize knockout chamber (discharge hood), the risk of entrainment associated with a higher air velocity is mitigated. This ensures capital cost is minimized by not making the drum any larger than it has to be.

Incorporation of a Controls System

A controls system is a powerful tool in optimizing dryer performance. A well-designed control system can give operators the ability to automate the start-up and shutdown process to minimize inefficiencies. It can also allow them to adjust parameters during normal operation to fine-tune the process for maximum efficiency. Some systems can even report and trend key operating parameters for later analysis on potential inefficiencies, predictive maintenance, and process troubleshooting. Both new and existing dryers can be outfitted with a controls package.

Optimized Off-Gas Handling

The off-gas system isn’t the first thing that comes to mind in improving dryer performance, but it can have an impact. Consider trying to maximize air flow in laying out ducting and of course, an industrial fan to help pull air through the system in order to create a negative pressure inside the dryer.

Select the Proper Duty

Part of the process of customizing a dryer to its specified application is to select a dryer that matches the level of duty required by the job. This means selecting proper materials of construction, the use of thickened shell sections where necessary, suitable drive components, and in general, ensuring the drum is built to withstand the rigors of duty.

Cutting corners on drum design and fabrication or using a one-size-fits-all approach may seem like a smart way to save on capital cost, but is a sure way to incur excessive downtime and maintenance costs.

Ensure the Dryer is Properly Maintained

No dryer will perform its best in a worn state, and some aspects of maintenance can not only affect process efficiency, but also product quality.

Allowing the condition of a rotary dryer to deteriorate can quickly cause it to become inefficient. Worn or missing flights can reduce heat transfer efficiency; degraded seals or thin spots in the shell can reduce efficiency and increase fuel costs (not to mention potentially cause irreparable damage to the shell).

For these reasons, following simple maintenance procedures set out by the OEM, as well as immediately addressing any issues that arise, helps to maintain product quality and overall operational efficiency.

Not Sure Where to Start?

Whether purchasing a new dryer or optimizing an existing one, the right path is not always clear and is, unfortunately, often clouded by an overwhelming amount of conflicting information. In either case, options are available to evaluate the choices at hand and make the best decision.

Try an Equipment Audit

In an existing production line, consider calling in an expert to conduct an equipment audit. The data gathered may differ depending on the service provider and the goal of the audit, but in general, can shed light on mechanical stability, troubleshoot existing issues, and identify opportunities for improvement.

A FEECO engineer works with on-site personnel to inspect a rotary dryer

Consider Testing

In purchasing a new dryer, the many factors that contribute to rotary dryer efficiency and product quality can make developing the right design challenging. Testing in a pilot facility can provide a valuable outlet for establishing process data points, material feedstock criteria, and de-risking commercialization by working through any material-specific challenges.

Testing reveals the process parameters necessary to reach the desired outlet moisture content and product quality, as well as informs on drum sizing decisions and defining criteria such as:

Retention time

Drum slope and speed

Feed rate

Air volume

Temperature profiles

Testing also helps to predict operational costs based on burner fuel usage and expected emissions/off-gas handling.

FEECO Innovation Center with pilot rotary dryer

Conclusion

The flexible design of rotary dryers makes them an ideal fit for a wide range of bulk solids drying applications. By tailoring the dryer design to the intended application with customizations such as custom flighting, a controls system, and more, as well as properly maintaining the dryer, processors can get the most out of their rotary dryer, maximizing performance, efficiency, and product quality.

Whether purchasing a new dryer or optimizing an existing one, producers looking to get the most out of their dryer can take advantage of testing facilities and equipment audits to ensure their dryer is expertly tailored to its unique application.

Shane Le Capitaine is a process sales engineer at FEECO International, where he specializes in bulk solids drying, fertilizer granulation, and rotary drum applications. Le Capitaine received a BS in Chemical Engineering from the University of Wisconsin-Madison and has more than 20 years of experience in his field. For more information, call 800-373-9347 or visit feeco.com.

You May Also Like