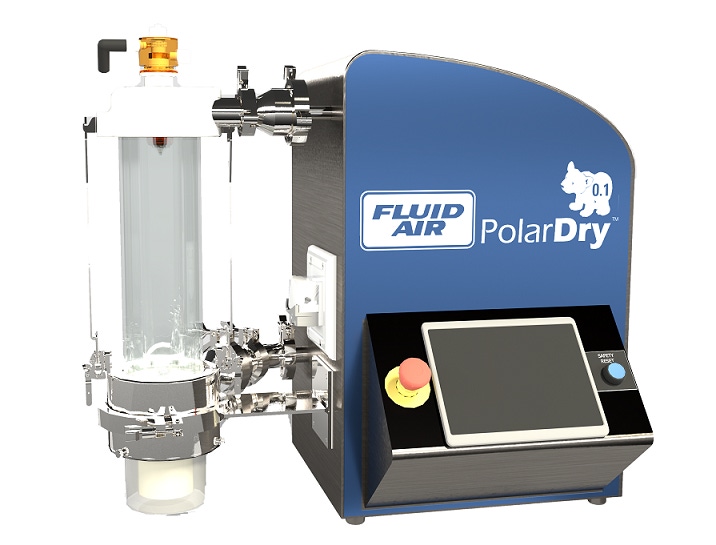

Fluid Air Introduces Electrostatic Spray Dryer

December 10, 2018

Fluid Air introduces the patent-pending PolarDry Model 0.1 electrostatic spray dryer. One of the defining features of the PolarDry Model 0.1 is the sheer diminutive size. The compact unit cuts down on the scope of its parent models but retains the same features. It boasts the cGMP design that stands as a testament to the level of operational consistency and controlled agglomeration the entire product line represents. The PolarDry Model 0.1 can be easily disassembled for autoclave sterilization.

The greatest aspect of this system is the opportunity it affords vendors: By producing small-scale samples with minimum product loss, the Model 0.1 allows for greater feasibility testing of expensive materials. The smaller dimensions allow the Model 0.1 to fit inside spaces such as most lab fume or containment hoods, where noxious solvents, potent APIs, and oxygen-sensitive materials can be safely tested. As a result, research of new products will be more efficient and cost-effective before committing to full-scale testing.

While other alternatives tend to keep the varying process components as separate but attachable fixtures, the Model 0.1 is an “all-in-one” system. Additionally, operation of the Model 0.1 will help mitigate maintenance and installation costs. Unlike same-sized competitor systems, this machine’s Batch Architect PLC controls come equipped with a data-logging feature. Furthermore, the Model 0.1 is compatible with optional high temperature and ultrasonic spray drying nozzles that ensures overall better microencapsulation. The ultrasonic nozzle is particularly suited for creating small particles less than 10 microns, and formulators still have the choice to use the Model 0.1 as a standard spray dryer with two fluid nozzles. Other benefits include zero need for an atomizing heat (nitrogen acts as both drying and atomizing gas) and low volatility loss.

Fluid Air, Aurora, IL 630-665-5001 www.fluidairinc.com

For related articles, news, and equipment reviews, visit our Drying & Thermal Solids Processing Equipment Zone

Click here for a List of Drying & Thermal Solids Processing Equipment Manufacturers

You May Also Like