Equipment

More Topics

- Bags & Bag Handling

- Drying

- Dust Collection

- Explosion Protection & Safety

- Industrial Feeders

- Instrumentation & Control

- Material Handling & Transport

- Mechanical Conveying

- Mixers & Blenders

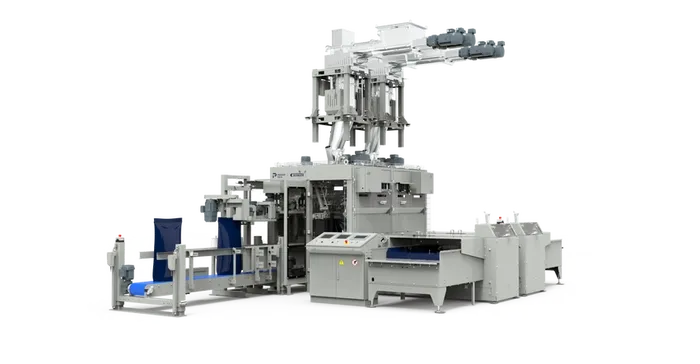

- Packaging Systems

- Particle Enlargers & Formers

- Pneumatic Conveying

- Screening & Separation

- Size Reduction

- Storage

- Valves, Gates, & Airlocks

- Weighing Systems & Scales

Kotzur opens new silo facility

Storage

Kotzur Opens New Silo Manufacturing FacilityKotzur Opens New Silo Manufacturing Facility

Bulk feed storage materials will be built at the new facility.

Sign up for the Powder & Bulk Solids Weekly newsletter.