Equipment

More Topics

- Bags & Bag Handling

- Drying

- Dust Collection

- Explosion Protection & Safety

- Industrial Feeders

- Instrumentation & Control

- Material Handling & Transport

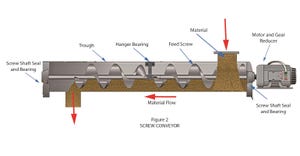

- Mechanical Conveying

- Mixers & Blenders

- Packaging Systems

- Particle Enlargers & Formers

- Pneumatic Conveying

- Screening & Separation

- Size Reduction

- Storage

- Valves, Gates, & Airlocks

- Weighing Systems & Scales

vee-cone blender

Mixers & Blenders

Sanitary Vee-Cone Blender is Equipped for Liquid AdditionsSanitary Vee-Cone Blender is Equipped for Liquid Additions

Unit blends dry and granular bulk materials uniformly, with or without liquid additions, typically in 15 to 30 minutes.

Sign up for the Powder & Bulk Solids Weekly newsletter.

.jpg?width=300&auto=webp&quality=80&disable=upscale)