Random-Flow Gravity Blending and Storage System

February 6, 2012

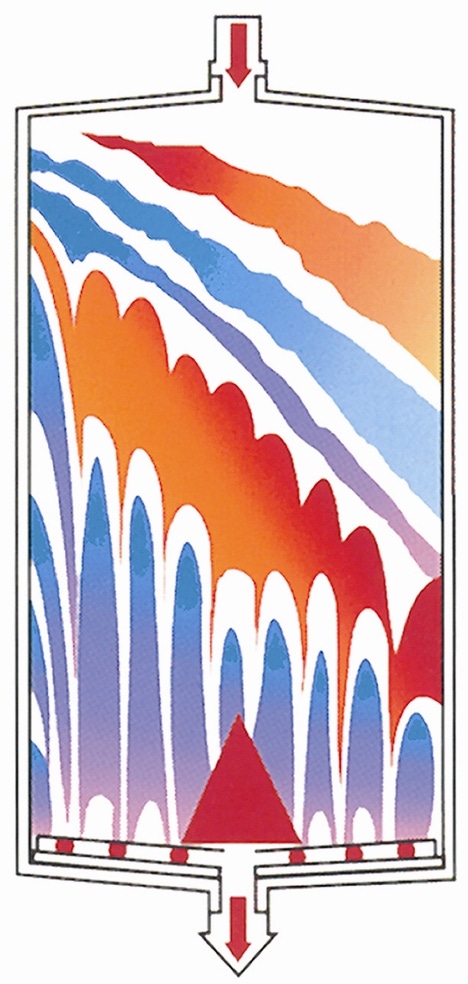

The advanced engineering of the Random-Flow blending and storage system uses gravity to meet the demand for a more energy-efficient, cost-effective system. The simple design and efficient process of the Random-Flow system achieves accepted blending efficiencies for dry, pulverized free-flowing particles, saving time and money. The system delivers increased capacity, productivity, and savings by decreasing power consumption, maintenance, dust emissions, and air flow. The silo floor consists of six aeration zones. Each aeration zone has six collection points. Blending is achieved by systematically withdrawing layered material through a gathering slide from a total of 36 collection points. The multiple collection points ensure uniform withdrawal of material about the entire floor area, closely resembling a mass flow discharge. This method of withdrawal allows fluidization from small zones to move material to the discharge point using very low power and low air volumes.

FLSmidth Inc., Bethlehem, PA 610-264-6011 www.flsmidth.com

You May Also Like