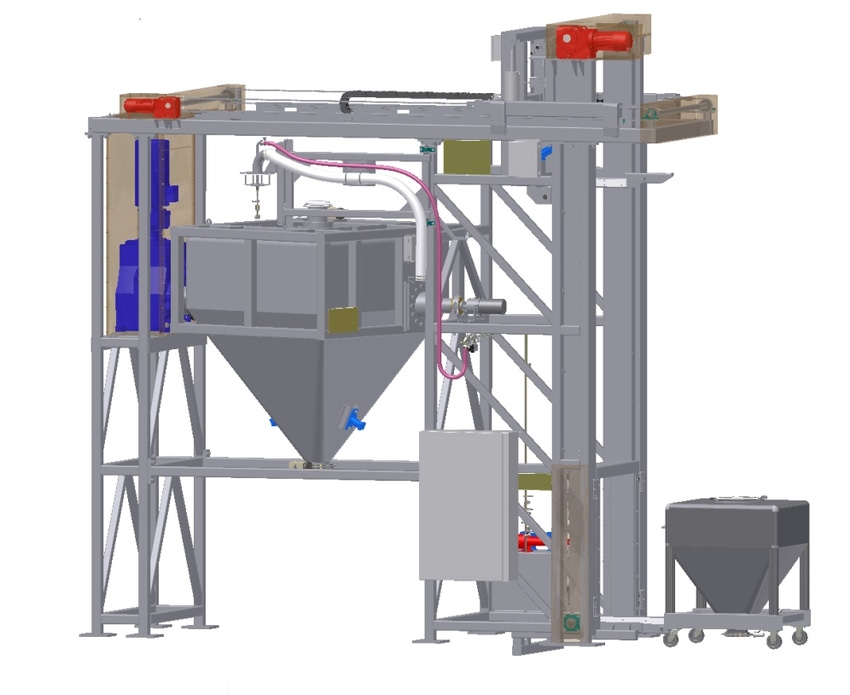

Mixing and Blending System

February 6, 2012

Custom Powder Systems manufactured a 5000-l blender for a customer that fits and can be loaded and discharged within limited manufacturing space and low ceiling heights. The CPS 20 offset blender angle uses the blender sides as baffles and causes the material to cross flow as it is being tumbled. Because of the weight of the blending vessel and its contents, CPS manufactured a bottle in support cage design as a cost savings to its client. In addition, CPS designed an automated vertical bin lift and shuttle system to transport raw ingredients in hopper bottom bins, discharge the bin into the new blending vessel, blend the ingredients using an automated “recipe” for RPMs and blending time, and discharge back into transport bins for transfer to the tablet press. This is an automated CIP system that includes booster and detergent pumps that cleans and dries the blending vessel for the next formulation. CPS custom designed, fabricated, automated, and tested the entire system.

Custom Powder Systems, Springfield, MO 417-868-8002 www.custom-powder.com

You May Also Like