Design Considerations for an Efficient Volumetric Screw Feeder

Designing an efficient volumetric screw feeder requires careful consideration of various factors.

July 7, 2023

Tom Picone, director of business development, Vibra Screw Inc.

A volumetric screw feeder is a crucial component in many industries where precise and consistent feeding of dry bulk materials is required. Achieving an optimal design for a (volumetric screw) feeder is essential to ensure accurate and reliable material flow into process. This article will delve into various design considerations and guidelines for developing an efficient volumetric screw feeder that meets specific application requirements. From screw geometry to hopper design and control systems, each aspect plays a vital role in achieving precise volumetric feeding.

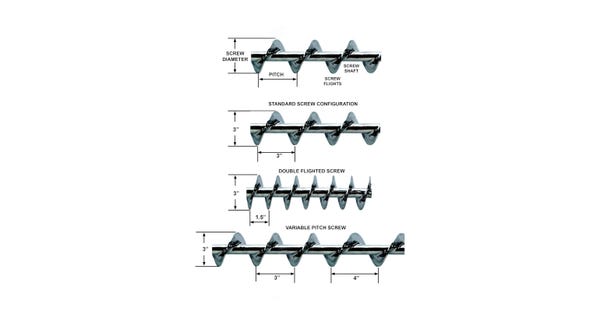

Screw Geometry

The screw geometry is a fundamental aspect of a volumetric screw feeder design. A screw with a constant pitch and diameter along its length ensures a consistent flow of material. By employing a single feed screw with a variable pitch, designers can optimize the feeding process. This configuration allows for controlling the material flow rate by adjusting the pitch along the screw length. The selection of the appropriate pitch variation depends on the material's flow characteristics and the desired feed rate. It is crucial to consider factors like material cohesion, angle of repose, and potential for flooding or flushing when determining the optimal screw geometry.

Feed Screw Length and Diameter

The length and diameter of the feed screw are important factors in achieving accurate volumetric feeding. The length of the screw in relation to the feeder’s trough affects the residence time of the material within the feeder, which can impact feeding accuracy. A longer screw provides more time for material to be transported, resulting in improved accuracy. A minimum of three flights in the trough produces the best results. The screw diameter should be chosen based on the processes required feed rate and the material's characteristics to prevent feed overloading or underfeeding. Oversized or undersized screws can lead to inconsistent flow (pulsation as the screw flights turn at discharge) and undersized screw just not making the required feed rate. Proper consideration of the feed screw length and diameter ensures the volumetric screw feeder can handle the required material flow while maintaining accuracy.

Screw Flight Configuration

The flight configuration of the screw refers to the shape and arrangement of the flights along its length. Different flight configurations, such as full pitch, short pitch, tapered, or cut flights, can be utilized to control the feed rate and improve accuracy. For instance, full pitch flights provide a higher volumetric capacity, while short pitch flights offer greater control over the feed rate. Tapered flights can help in material compression and flow control, while cut flights can minimize material backflow. Selecting the appropriate flight configuration depends on the specific material characteristics, required feed rate, and desired feeding accuracy. Proper understanding of these factors allows designers to optimize the volumetric feeding process.

Screw Speed and Rotation

The rotational speed of the screw directly influences the feed rate of the volumetric screw feeder. It is crucial to select an appropriate speed based on the material's flow characteristics and the desired feed rate. Different materials have varying cohesive properties, angle of repose, and tendencies for flooding or flushing, which must be considered. Note that screw speed and rate output are typically not linear (i.e. as screw speed increases rate out increases proportionally over the full range of the screw speed). Depending on the handling characteristics of the feed material as the screw speed increases over 100 RPM (on a single screw feeder) the feed rate output decreases. Materials with varying bulk densities, particle sizes, or flow characteristics may exhibit nonlinear behavior.

A comprehensive understanding of the material's behavior is necessary to determine the optimal screw speed that prevents material compaction, segregation, or erratic flow. Testing and experimentation may be required to fine-tune the rotational speed for optimal performance.

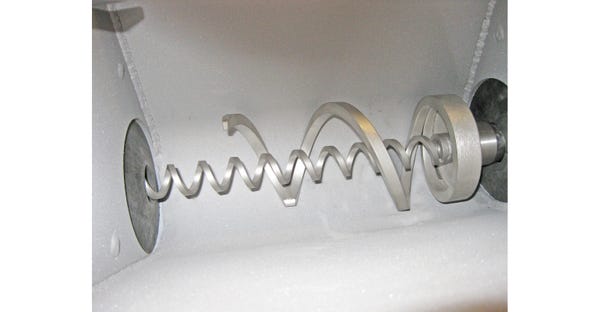

Overwrap and Conditioner Screws

Overwrap and conditioner screws are added devices in the feeder trough. They serve different purposes and exhibit performance differences. Which one is chosen (conditioner or overwrap) depends mainly on the handling characteristics of the material being fed and the main feed screw size.

Screw feeders feed or push material from the back of the trough forward towards to front of the trough.

The overwrap screw encircles the feed screw which is typically one to 2 in. larger than the feed screw (hence 2-in.-diam feed screw, 4-in. overwrap screw). The overwrap screw prevents material bridging and performs some material conditioning for constant bulk density. Additionally, the overwrap helps assure that the feed screw flights are completely filled with material. Ideal for sluggish powders that do not flow well on their own like flour, starch, lime, and sugar.

The conditioning screw like the overwrap screw encircles the feed screw, but the conditioning screw has two different flights. The first flight pushes the material from the back of the trough, the second reverse flight pushes the material from the front of the trough to the middle. This action prevents material bridging or tunneling and prevents highly compressible material from being packed in the front of the feeder trough. Ideal for light density, sticky or compressible powders like titanium dioxide, stearates, and fumed silica.

Hopper Design

The hopper serves as a reservoir for the material being fed and plays a significant role in achieving uninterrupted material flow. A well-designed hopper should prevent bridging or arching, ensuring a consistent supply of material to the screw. The hopper's slope angle is a critical factor in facilitating material flow. It should be chosen carefully to avoid material hang-ups or stagnant zones. Additionally, incorporating features like hopper vibration or agitation mechanisms can further enhance material flow and prevent blockages. Adequate consideration of the hopper's geometry, outlet size, and material flow properties is essential for optimizing volumetric feeding efficiency.

Drive System

The drive system of a volumetric screw feeder is responsible for providing consistent and precise rotational speed to the screw. Common drive systems include electric motors with variable frequency drives (VFDs), DC/SCR, hydraulic or pneumatic drives. The drive system should be robust enough to handle the required torque and speed range. Additionally, it should provide accurate speed control to meet the desired feed rate. A well-designed drive system with proper torque monitoring and feedback mechanisms ensures reliable and consistent feeding. The selection of the drive system should consider factors such as power requirements, maintenance considerations, and potential variations in material characteristics or feed rates.

Control System

Implementing an effective control system is essential for maintaining accurate volumetric feeding. The control system may include sensors, feedback loops, and automation to monitor and adjust the feed rate based on desired setpoints and real-time conditions. Sensors can provide feedback on screw speed, material level in the hopper, or material flow rate, enabling the control system to make necessary adjustments to maintain accurate feeding. Automation allows for precise control and can incorporate features like data logging, remote monitoring, and integration with other process equipment. A well-designed control system enhances the overall performance of the volumetric screw feeder and ensures consistent and reliable material feeding.

Material Considerations

Understanding the properties of the material being fed is crucial in designing an efficient volumetric screw feeder. Factors such as bulk density, particle size, flowability, moisture content, and abrasiveness influence the design choices, including hopper angles, screw materials, and wear-resistant coatings. Materials with cohesive or abrasive properties may require additional measures, such as specialized screw materials or liners to minimize wear and prevent material build-up. Material testing is essential to gather accurate data on these properties and guide the design process. By considering the specific characteristics of the material, designers can ensure optimal performance and longevity of the volumetric screw feeder.

Conclusion

Designing an efficient volumetric screw feeder requires careful consideration of various factors. From screw geometry and hopper design to screw speed, flight configuration, and control systems, each aspect contributes to achieving accurate and consistent feeding. Additionally, understanding the material characteristics and incorporating appropriate measures for handling cohesive, abrasive, or other challenging materials is vital. It is important to collaborate with experienced professionals or engineering firms specializing in bulk material handling to optimize the design and ensure the volumetric screw feeder meets the specific application requirements, resulting in improved operational efficiency and productivity.

Tom Picone is director of business development at Vibra Screw Inc. (Totowa, NJ). Vibra Screw manufactures a line of material handling equipment, including, loss-in-weight feeders, weigh belts screw feeders and bin dischargers. For more information, email [email protected] or visit www.vibrascrew.com.

You May Also Like