The Danger of Combustible Nanomaterials in Battery Manufacturing

What battery makers need to know to prevent combustible dust explosions.

June 26, 2023

Rick Kreczmer, President, RoboVent

Nanomaterials are increasing used in battery production to increase energy density and improve battery performance. These may include nanoparticles of metals, metal oxides, conductive polymers, lithium salts, and silicon- or carbon-based nanomaterials. The unique physical and chemical characteristics of nanomaterials used in battery production can create a significant combustion risk under the right conditions. Battery manufacturers working with combustible nanomaterials should conduct a dust hazard analysis (DHA) and implement dust safety strategies to mitigate the risks of a combustible dust explosion.

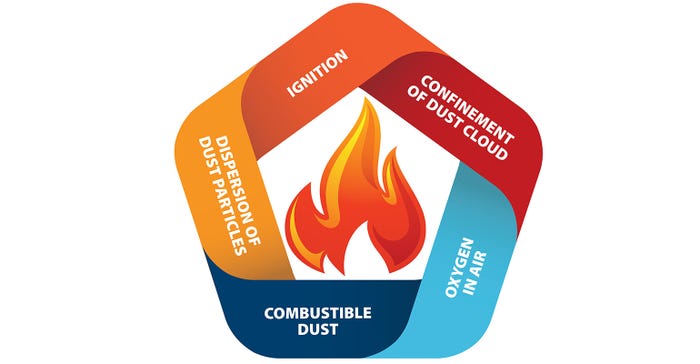

How does a combustible dust explosion happen?

Combustible dust explosions happen when five elements come together, known collectively as the “Explosion Pentagon.” These include 1) a fuel source (i.e., the combustible dust); 2) oxygen (readily present in the air); 3) dispersion of the dust in a cloud; 4) containment of the dust cloud (e.g., in enclosed process equipment, storage bins or the dust collection system); and 5) an ignition source. All five elements must be present for an explosion to occur.

What Is a dust hazard analysis, and when is it required?

A Dust Hazard Analysis (DHA) is a systematic review of facilities, processes, and operations where combustible dust is present. It identifies hazards and assesses potential risks of a dust explosion. A DHA is necessary whenever a manufacturing or processing facility works with potentially combustible dust, defined as any dust with an ST Class greater than zero. (The ST Class is a measure of potential explosion severity, with classes ranging from zero to three.) In the case of battery production involving combustible nanomaterials, a DHA should be a standard part of the safety protocol. A DHA must be conducted every five years or when making a substantive change to materials, processes and systems.

What regulations and standards govern combustible dusts and the DHA process?

In the U.S., battery manufacturers must comply with regulations for combustible dust outlined by the Occupational Safety and Health Administration (OSHA) in their combustible dust standards for general industry. Manufacturers must also comply with standards set by the National Fire Protection Association (NFPA) for handling combustible dusts and particulate solids. NFPA 652, Standard on the Fundamentals of Combustible Dust, outlines the requirements for the DHA. Further information can be found in NFPA 654, Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing and Handling of Combustible Particulate Solids, and related NFPA guidelines. (Note: NFPA 652, 654 and several additional standards will be combined into the new NFPA 660 effective fall of 2024.)

How do I know if my dust is explosive?

The explosivity of dust (ST Class) is usually determined through laboratory testing. Several characteristics of dust can indicate its explosiveness, such as particle size, moisture content, morphology, and chemical composition. In general, smaller particles have higher a risk of explosion; dust particles less than 420 microns in diameter are usually considered combustible. Nanomaterials are much smaller than this, with a size range of 1 to 100 nanometers (0.001 to 0.1 microns). This small size creates more surface area to react with oxygen, while their light weight makes them more likely to become airborne in a cloud. As a result, most nanomaterials are considered combustible, and they usually present a higher combustion risk than larger particles of the same material.

Testing is conducted to measure the Deflagration Index (Kst), Maximum Explosion Pressure (Pmax), Minimum Ignition Energy (MIE), Minimum Explosive Concentration (MEC), and other indices. Testing must be conducted by a lab accredited by the American Association for Laboratory Accreditation (A2LA). In some cases, manufacturers may be able to use published values for explosivity, if the materials they are using are substantially similar to those used for the published values. However, because of the high variability in nanomaterials, it is generally advised to have testing completing on the specific dust used or created in manufacturing processes (this may be required in some cases).

What are the steps in a dust hazard analysis?

The DHA process will vary depending on the specifics of the facility and processes, but in general will include the following steps.

Identification of combustible dusts (and material testing if required).

Process characterization to identify where dust is generated, accumulates, or disperses in a cloud and specific risks at each point such as ignition sources, presence of oxygen, or containment of the dust cloud.

Hazard identification, including quantification of risk (based on both likelihood and severity) at each point in the production process and documentation of current safeguards in place.

Mitigation recommendations to address identified hazards.

Documentation and verification of mitigation efforts once they are made.

Who can conduct a dust hazard analysis?

A DHA should be conducted by professionals experienced in identifying and evaluating combustible dust hazards. This could be a qualified internal team, but it is usually recommended that manufacturers engage external consultants with specific expertise in dust explosion hazards. An accredited engineering consulting firm can provide this service.

How can facilities reduce the risk of a combustible dust explosion?

Battery manufacturers can take several steps to protect employees, equipment and facilities from a combustible dust explosion. These include:

The use of industrial dust collection systems to prevent nanomaterials from accumulating or migrating through the facility. Particular care should be taken to avoid accumulation of dust clouds inside enclosed spaces.

Changes in processes or facility setup to reduce explosion risks, such as removing ignition sources, adding spark control, using an inerting environment, or modifying processes to minimize dust cloud formation. This may require modifications to equipment design or process steps.

Good housekeeping and material handling practices to prevent accumulation of dust on surfaces and minimize the formation of dust clouds. Vacuums designed for collection of combustible materials and/or wet cleaning methods should be used.

The use of explosion venting and isolation systems to mitigate the impact of an explosion inside the dust collection system or enclosures.

What safety elements are required for the dust collection system?

The dust collection system, while a vital element of combustible dust safety, also represents one of the greatest points of explosion risk. Dust collectors used with combustible materials must have safety elements to reduce the risk of an explosion and mitigate the impact of a combustion event.

Ensure that the system has adequate airflow to prevent dust from accumulating in explosive concentrations within enclosures or the dust collection system.

Explosion venting must be used for dust collection systems that collect explosive material. The explosion vent is designed to pop out to release excess pressure before it rises to explosive levels.

The dust collector should also be equipped with a fire suppression system and other deflagration elements, such as an isolation valve to prevent a pressure wave from propagating back into the facility and a rotary airlock to prevent dust from escaping the collection bin.

Stay on top of maintenance, such as filter changes and dust bin emptying, and regularly clean and inspect the system to ensure that it is working properly.

Download the Visual Guide to Combustible Dust to learn more about the DHA and combustible dust mitigation.

Rick Kreczmer, President, RoboVent, is an industrial air filtration industry veteran with more than 24 years of experience in sales and executive management. As President of RoboVent, he has led the company through new product innovation and market initiatives to lay the foundation for continued growth and profitability in an evolving manufacturing environment.

You May Also Like