Equipment

More Topics

- Bags & Bag Handling

- Drying

- Dust Collection

- Explosion Protection & Safety

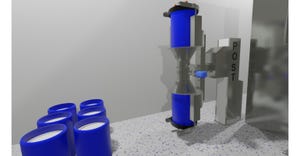

- Industrial Feeders

- Instrumentation & Control

- Material Handling & Transport

- Mechanical Conveying

- Mixers & Blenders

- Packaging Systems

- Particle Enlargers & Formers

- Pneumatic Conveying

- Screening & Separation

- Size Reduction

- Storage

- Valves, Gates, & Airlocks

- Weighing Systems & Scales

Key Pak Cold Form

Bags & Bag Handling

Keystone Introduces F=1 Child-Resistant Blister CardKeystone Introduces F=1 Child-Resistant Blister Card

Construction meets highest child resistance standards while remaining senior-friendly.

Sign up for the Powder & Bulk Solids Weekly newsletter.