Equipment

More Topics

- Bags & Bag Handling

- Drying

- Dust Collection

- Explosion Protection & Safety

- Industrial Feeders

- Instrumentation & Control

- Material Handling & Transport

- Mechanical Conveying

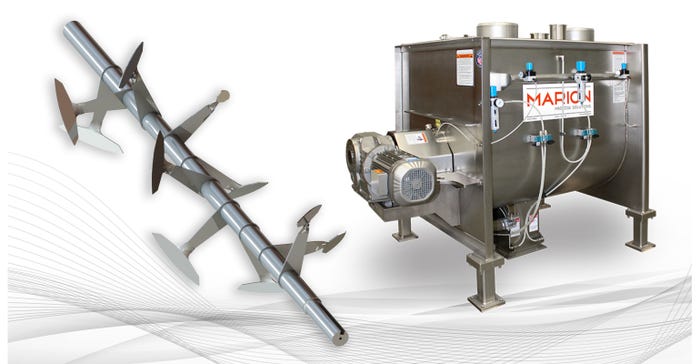

- Mixers & Blenders

- Packaging Systems

- Particle Enlargers & Formers

- Pneumatic Conveying

- Screening & Separation

- Size Reduction

- Storage

- Valves, Gates, & Airlocks

- Weighing Systems & Scales

CSB issued finalized report on fatal Yenkin-Majestic explosion.

Explosion Protection & Safety

CSB Releases Final Report on Fatal Vapor ExplosionCSB Releases Final Report on Fatal Vapor Explosion

A flammable vapor explosion and fire occurred at the Yenkin-Majestic paint facility in Columbus, OH, in 2021.

byStaff

Sign up for the Powder & Bulk Solids Weekly newsletter.