Volkmann Introduces Automated Depowdering Station

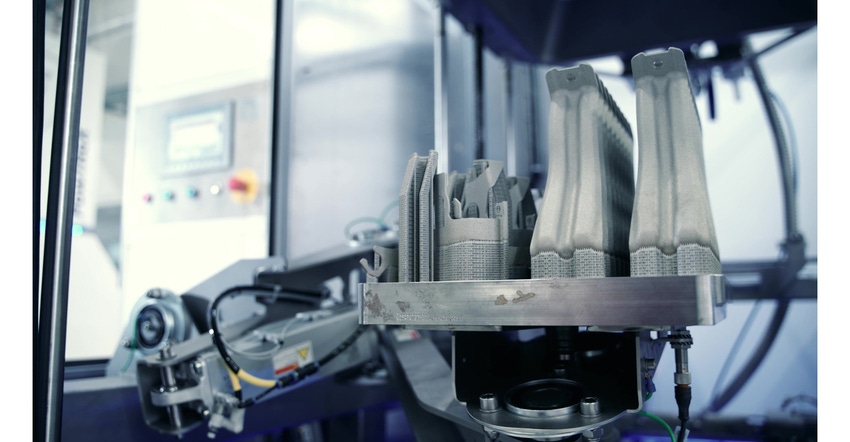

Depowdering station automatically cleans unused metal powder from 3D-printed build jobs.

March 21, 2023

Volkmann USA introduces an automated depowdering station (DPS).

Developed to reduce metal powder waste and promote its safe recovery and reuse, the new depowdering station automatically removes unused metal powder and powder agglomerates left in the build box after 3D printing. With the build frame loaded inside, the proprietary technology combines compressed air, gravity, and a vibratory action to completely remove the remaining material, ensuring the build job is clean and ready for finishing, and the build box and frame are clean and ready for the next job. The valuable metal material is neatly collected in a container and automatically transferred via the companion Volkmann PowTReX conveying system for screening and recycling or return to storage.

Proven in 3D printing demonstrator systems at BMW Group and GKN Additive as part of the Industrialization and Digitalization of Additive Manufacturing (IDAM) research project, the depowdering station enables additive manufacturers to recover metal powders without compromising the safety of the operator or the cleanliness of the work environment. 3D print quality and worker safety are improved, material costs are reduced, and the need for secondary metalworking operations is minimized.

The depowdering station is suitable for use with 3D printers from several manufacturers and may be tailored for each installation.

Volkmann Inc., Bristol, PA 609-265-0101 www.volkmannusa.com

About the Author(s)

You May Also Like