Modern Screener in Old Water Mill Produces High-Quality Flour

January 4, 2012

|

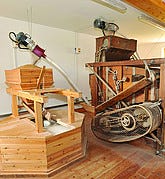

The mill still uses a water wheel to turn two millstones to grind wheat into flour. |

If visitors from centuries past returned to a familiar footpath by the River Gowry in northern England, they might be shocked by changes that have taken place, but there would be one comforting sight: the old mill with its large water wheel (although our visitor would probably be surprised to see a steel wheel rather than a wooden one). Powered by a stream diverted from the river, the wheel works through gears to grind wheat into flour for making bread.

Inside the mill the wheat is ground between two flat, 4½-ft-dia millstones, a method employed for hundreds of years. However, our time traveler would likely be puzzled by some of the equipment, in particular an electrically driven centrifugal screener. The Centri-Sifter centrifugal sifter was supplied by Kason Corp., Millburn, NJ, and recovers the mill’s two basic products: white and whole meal flours.

There has been a water mill at the site since the 13th century, but the present building, Walk Mill, is no older than the screener, despite its aged appearance. Rebuilt as a replica of an earlier mill, the new facility started up in 2008.

The last mill on the site ceased production in 1915 and only the footprint of the building was left, says Ben Jones, a partner in the family-owned business, who is in charge of mill operations. “We dug the foundations to find the footprint of the building and we also had a lot of photographs of the old mill. From the footprint and the pictures we were able to construct a building that is exactly like the old mill on the outside.”

Wheat is at Hand

Located on the fertile Cheshire plain, close to the historic city of Chester, Walk Mill is surrounded by roughly 1000 acres of wheat fields that were acquired by the Jones family some years ago. “We have always been farmers,” says Jones, “and after we bought this land we decided to rebuild the mill.”

Wheat is harvested from the fields, dried to reduce the moisture content and cleaned to remove chaff. It is then taken to the mill in a sealed trailer and loaded into a hopper on the first floor. The hopper has a capacity of 4400 lb, which is enough to meet the mill’s needs for four to six days, depending on the rotation speed of the water wheel.

From the floor hopper the wheat is moved by an auger conveyor to a smaller feed or transit hopper of 110 lb capacity, located above the millstones. The grains fall from the bottom of the feed hopper to the millstones, where they are ground into flour.

Walk Mill uses two burr stones, made of hard, dense French granite. The stones are positioned horizontally, one above the other. The lower stone, called a bedder, is fixed, while the upper one (the runner stone) rotates. Wheat from the hopper falls into a hole in the center of the upper stone and gradually moves to the periphery of the stones via shallow grooves in the stones. The tiny gap between the stones is adjusted to produce white or whole meal flour, the latter being more coarse because it contains bran.

Both the stone rotation and the feed rate from the hopper are governed and synchronized by a shaft that is geared to the water wheel. The bottom end of the shaft is attached to the runner stone and carries the weight of the stone as well as rotates it.

An Old Damsel Controls the Flow

|

The Centri-Sifter centrifugal screener separates the desired flour from the rest of the ground material. The separated flour in 55-lb sacks is ready for shipping. |

Grain trickles from the hopper along a vibrating wooden trough, called a shoe. The vibration is imparted by a forged metal device, called a damsel, that is attached to the upper end of the shaft. The damsel, incidentally, was retrieved from the earlier mill.

“It’s self regulating,” says Jones. “If the water flow increases, the feeding and milling operations increase at the same rate.” Jones adds that a shaft rotation rate of about 40 rpm yields the best quality of flour. The relatively slow, gentle, and cool process avoids overheating of the flour, and preserves all the good parts of the grain: protein, oils, vitamins, sugars, starches, and bran.

As the flour leaves the periphery of the millstones it is swept by a blade attached to the upper stone and falls into a 28-lb transit hopper. An auger transfers the product to a spout that feeds the Centri-Sifter screener, which separates the desired flour from the rest of the material. The model GOB-SS machine has a sifting area of 171 sq in. It is driven by a 2-hp motor and can process up to 1540 lb/hr, well beyond the mill’s capacity of 176 lb/hr.

The screener is a compact centrifugal machine, with a cylindrical sifting chamber that contains a cylindrical screen of nylon mesh. Flour is fed pneumatically into a vertical feed inlet at one end of the unit, then redirected by a feed screw into the chamber, which is oriented horizontally.

Centrifugal Force Makes for Efficient Separation

Rotating helical paddles within the chamber continuously propel the flour against the screen and the centrifugal force accelerates the particles through the screen openings. The rotating paddles, which make no contact with the screen, also break up soft, agglomerated material. The separated flour is directed to a chute, from which it drops directly into a 55-lb sack for shipping. When the sack is full the auger is stopped until a new sack is in place.

Walk Mill uses two screen sizes: 38 mesh (500 µm) for white flour and 12 mesh (1500 µm) for the coarser whole meal flour. “Typically we produce white flour for four days, because we sell more of it, and wheat flour for one day,” says Jones.

|

Auger conveyors move wheat to feed hoppers located above the millstones which grind the grain into flour. |

In the case of the finer, white flour the product passes through the screen for bagging, as explained above. Coarser, waste material is retained by the screen and moves along the chamber to the far end, where it is recovered through a second discharge spout. In the case of bran, fine waste material is ejected through the screen, while the bran is retained and collected from the second outlet. All the waste is bagged and used for feeding pigs.

The company found the centrifugal sifter through an Internet search and bought it after seeing a demonstration at Kason’s facility in Stoke-on-Trent, England. The screener achieves a good separation, with no wasted product, and the quality of the flour is excellent, says Caroline Jones, Ben’s daughter, whose principal responsibilities are baking and running the company tearoom for visitors (her mother handles the accounts and her brother farms the land).

“The machine is very easy to operate and there is no problem with screen clogging,” she says. “We occasionally dust it down, but basically it cleans itself.”

Walk Mill serves two markets. The 55-lb sacks are shipped to upscale restaurants and hotels that make their own bread. For the retail market, flour is delivered in 3.3-lb bags that are filled by hand from the larger sacks.

In addition to white and whole meal flour, Walk Mill sells two other types of flour: malted flour, which is white flour plus malt flakes and malt extract, and self-raising flour (white flour plus baking powder) for making cakes. Malted flour is packaged for both wholesale and retail sale and self-raising flour is sold only retail.

Visitors who come to see the mill can entertain themselves by looking through a sealed glass window to watch the stones steadily grind away. After that they can enjoy fresh bread, cakes, and scones in the company teashop.

For more information on Walk Mill, call +44 (0) 1829-749373 or visit www.walkmillflour.co.uk. For more information on Kason Corp., call 973-467-8140 or visit

You May Also Like