Level Measurement System Successfully Monitors Barley

May 12, 2011

|

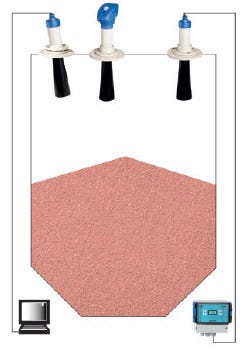

UWT (UK) Ltd’s Nivowave 5015 continuous monitoring device |

UWT UK Ltd. was contracted to supply and install a full continuous level monitoring system for Aberdeen Grain, one of the UK’s largest grain storage facilities.

Aberdeen Grain recently installed a new barley drying plant at its Whiterashes site in Aberdeenshire and during harvest, the plant operates for 12 hours per day, seven days a week. Three new 420-ton silos provide a drying capacity of 7000t of feed grain and 3000t of malting barley. With high volumes passing through the silos, it is essential that the volume of each silo can be monitored in real time and with complete accuracy during filling and discharge.

UWT UK Ltd addressed the range of conditions to consider with this application (caking, dusty environment, material with changing temperature and humidity, explosive, diverse grain sizes, specific space constraints, high flows, and large measurement distances) and installed a Nivowave NW5015 acoustic wave level measurement system on each silo.

|

Accoustic wave technology is used to generate sonic waves from 5KHz to 50KHz. |

Accoustic wave technology is used to generate sonic waves from 5 to 50 KHz, which reflect off the surface of the material to be measured and cause an echo. The time delay between the sent signal and received echo is analyzed and temperature compensated to provide the full level display and output signal.

The Nivowave NW5015 is a 15kH transducer with a 4-20mA output and is linked via a Modbus connection and the Nivowave system is able to show via a touch screen display all three silo volumes during filling and discharge. The output can be shown as a percentage, level or volume and has a 10-year data retention internal memory.

|

Aberdeen Grain at its Whiterashes site in Scotland, UK |

With a -40ºC to +70ºC IP67 housing and built-in digital display for easy commissioning the Nivowave NW5015 has proven itself to be the right product for Aberdeen Grain.

“As UWT (UK) clearly claims, their product is simply working which is the result we wanted,” said Steven Mearns, store manager at Aberdeen Grain.

For more information on the Nivowave system and products tailored for solutions to level control situations, call +44 (0) 8454 810463 or visit www.uwtuk.com.

You May Also Like