Editor's Choice

May 12, 2011

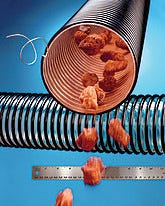

Large Diameter Static Dissipative Hose

Large Diameter Static Dissipative Hose

This line of abrasion-resistant static dissipative hose features an embedded ground wire, a smooth interior, an external helix, and now comes in sizes up to 8 in. I.D. FlexStat static dissipative hose is constructed from polyurethane with an embedded copper grounding wire and is reinforced with a rigid external ABS helix. Featuring sizes from 1¼ to 8 in. I.D., this hose provides 108-1010 Ohms/sq surface resistivity to prevent static buildup and improve plant safety in a wide range of applications. Suitable for powders, light bulk pneumatic conveying, dust collection, and paint spray extraction, the hose has a smooth interior for unrestricted flow and the external wear strip provides drag-resistance. Wall thicknesses for this durable hose range from 0.040 to 0.060 in. and they are offered in standard 25- and 50-ft lengths with plain ends. Flexaust, Warsaw, IN 800-343-0428 www.flexaust.com

Horizontal Fluid Bed Separator

Horizontal Fluid Bed Separator

The HFS horizontal fluid bed separator is available for relatively low throughput rates – upwards of approximately 800 kg/hr and suitable for the cleaning of pellets and granules in the plastics processing industry. With the fluid bed separator it is possible to clean thoroughly and effectively even the most difficult of products, such as brittle, fragile, or rubbery bulk materials. The slow cleaning process protects the product and consumes only a minimum of air and energy. The separator is ideal for use not only in plastics processing installations but also in food processing applications and in other applications where the purity of the product is decisive for the manufacturing process, further processing, or the quality of the ultimate product. Coperion Corp., Ramsey, NJ 201-327-6300 www.coperion.com

Salt Drying System

Salt Drying System

This new salt drying system features an integral baghouse collector set atop a vibrating fluid bed dryer to capture up to 100% of fine salt particles entrained in the airstream. Returning the fines to the process for recovery as finished product, the Witte bulk salt drying system eliminates the product waste required in systems using cyclones to exhaust process air along with their need for dust collection, conveying, drum handling, and other downstream equipment. Costs for product loss, waste disposal, equipment maintenance, and downtime are eliminated. Further, by placing the reverse pulse jet baghouse collector directly over the fluid bed, the energy-efficient system also permits 50% of the hot exhaust air to be captured and recycled to reduce energy requirements while cutting the volume of air exhausted by 50%, addressing a key factor in quickly securing permits from the EPA. The system is ideal for drying road salt, rock salt, water treatment salt, sea salt, food grade table salt, and other salt products. Witte Company, Inc., Washington, NJ 908-689-6500 www.witte.com

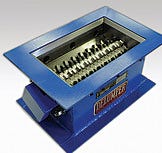

Powerful Crusher

Powerful Crusher

The ultra compact Delumper 1065N is a crusher specially designed to handle compressed products, silver, and other agglomerates, minerals, plastics, and more. This unit has a hardened alloy one-piece cutting drum fitted with more than 200 tapered teeth. The result is a crusher with a smooth, effective operation that easily processes metals, minerals, and other bulk solids, reducing them with minimal fines, overgrind, or heat-rise. The DC1065N is designed with a one-piece body, operates at low speed, and features low noise and vibration, and easy assembly. The crusher can be provided with a direct gear drive or belt drive as required. It is available in carbon steel as well as 304 and 316 stainless steel construction. The unit is only 7.5 in. from inlet to outlet and features a 6 5/8 x 11 in. inlet opening. The crusher is supplied with rugged outboard bearings protected by shaft seals to keep powders within the cutting chamber. Product is crushed by the cutting drum intermeshing with special sizing combs and discharged out the bottom. Franklin Miller Inc., Livingston, NJ 973-535-9200 www.franklinmiller.com

Sanitary Stainless Steel Hydraulic Container Dumper

Sanitary Stainless Steel Hydraulic Container Dumper

This unit discharges containers of food products into an existing hopper at 63 in. above floor level. The unit features sanitary, wash-down duty, tubular 304 stainless steel construction with continuous TIG welds, and no tube penetrations. The dump carriage features a pipe bottom and openings to allow debris to fall through. Equipment includes stainless steel machine guarding, PLC controls, and a color touch-screen operator interface for safe, efficient operation. Units are custom designed for your requirements with discharge heights to 40 ft, for any size or weight container. Material Transfer & Storage Inc., Allegan, MI 800-836-7068 www.materialtransfer.com

You May Also Like