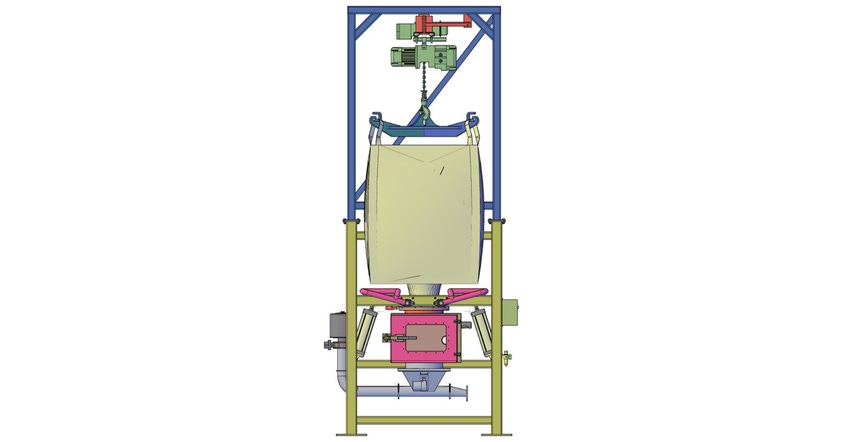

AFC Introduces Sanitary Bulk Bag Unloader

The bag discharge station features stainless steel, polished finish

Automated Flexible Conveyor unveils a bulk bag unloading station suitable for sanitary processing.

Complying with FDA requirements, the sanitary AFC BBU features 316L stainless steel frame construction, continuously welded seams, food-grade drive lubricant, and a surface finish polished to an Ra ? 0.8 µm. The potential to harbor fine material is virtually eliminated along with concern for product contamination due to contact with the unloading equipment.

Ideal for food, petfood, pharmaceutical, and nutritional product manufacturers, the AFC BBU automatically unloads bulk bags containing up to 4,000 lb of powders, pellets, granules, and other bulk ingredients for contained discharge into a hopper, conveyor or other location. The dust-tight bulk bag discharger may be custom-configured in nearly any size to accommodate any hygienic processing application.

Testing with filled FIBCs, sacks, and other bulk bags is offered in person and online by live stream in the company’s on-site test center.

Automated Flexible Conveyor Inc., Clifton, NJ 800-694-7271 afcspiralfeeder.com

About the Author(s)

You May Also Like