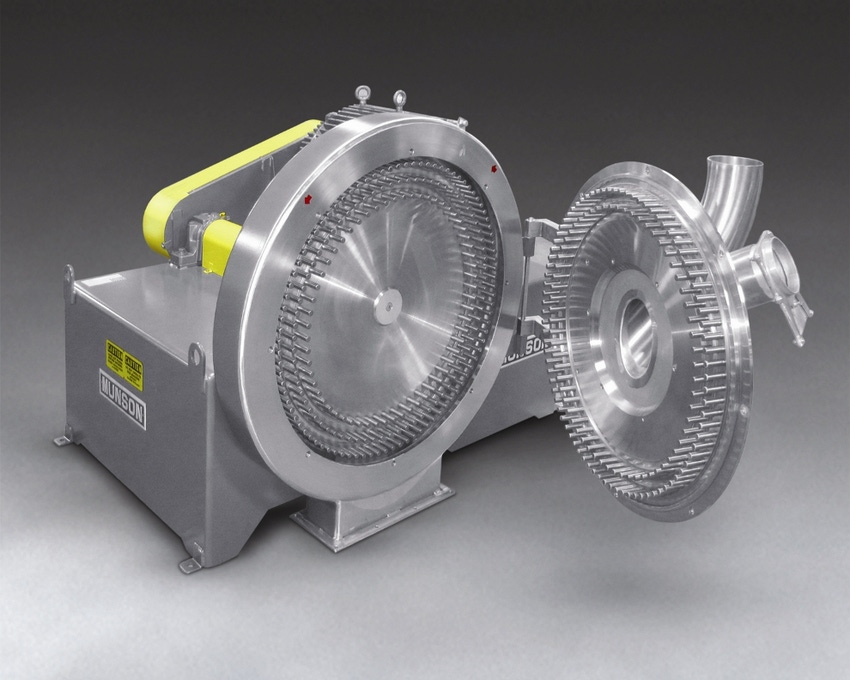

Sanitary Pin Mill Reduces Friable Solids

February 6, 2012

This 34-in. sanitary stainless steel model CIM-34-SS pin mill provides coarse to fine grinding of friable powders, flakes, and granules into controlled particle sizes. High-speed rotation of the inner disc creates centrifugal force that accelerates bulk material entering the central inlet of the opposing stationary disc. As material travels from the center to the periphery of the discs at high speed, it passes through a path of five intermeshing rows of rotating and stationary pins, with the desired tight particle size distribution obtained by controlling the rotor speed. Setting the infinitely variable rotor speed between several hundred rpm and 5400 rpm provides the flexibility to use the machine for coarse grinding and de-agglomerating as well as for fine grinding down to 400 mesh. Vertical orientation of the mill housing results in a smaller footprint than horizontally oriented units, and provides instant access to product-contact surfaces.

Munson Machinery Company, Inc., Utica, NY 800-944-6644 www.munsonmachinery.com

You May Also Like