Cage Mill Design, Configuration, and Application

February 28, 2020

Cage mills are a practical solution to applications that require one-step crushing to produce the final product. And it has been that way since 1876, just about the time Mark Twain published his timeless classic, "The Adventures of Tom Sawyer." But there's a reason this 144-year technology is still relevant and an excellent size reduction method for the modern stone age.

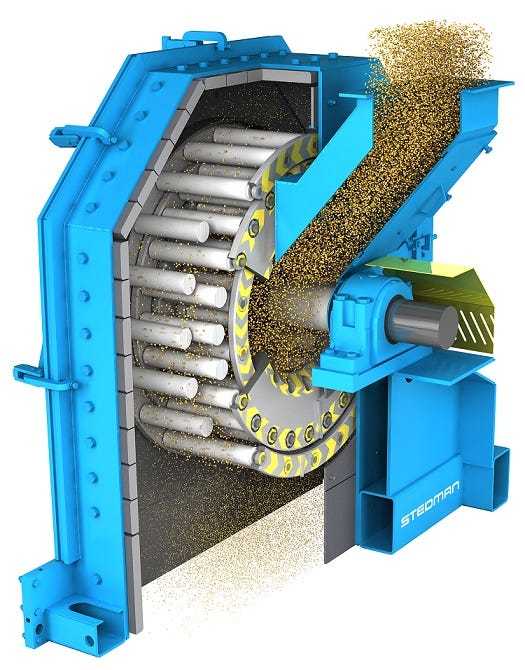

"The Disintegrator" was the original name the inventor gave the cage mill because the process repeatedly forces the materials to break into pieces through multiple stages. You could say, the action of the cage mill is controlled chaos, tempered by probability and gravity. Once you understand the cage mill's construction, you'll see how the different models are suited to coarse, medium-fine, and fine size reduction processes. Example products for each cage mill type will illustrate the solution to specific problems.

Its unique design is key to understanding the cage mill. It works like this: Feed enters the innermost cage and is reduced by the action of counter-rotating cages as it's struck from one direction and then the other direction and so on through the number of rows (one through six). This cage mill characteristic minimizes the quantity of oversized particles found in the final product's particle size distribution. Adjusting the cages' speeds defines the final particle size. In general, as the number and velocity of the cages increases, higher percentages pass smaller mesh sizes.

In most applications for fine calcium carbonate grinding, for example, one pass will meet specifications. That eliminates the need for another piece of equipment and saves a step.

Cage Mill Configurations for Different Applications

Single-row cage mills are a legacy line predating horizontal shaft impactors in North America. The limestone, sand, and gravel production industries use these robust, compact, simple-to-operate impact crushers. Accepting large feed sizes, producing cubic-shaped particles, and processing high tonnages (up to 800 tn/hr) are hallmarks of the single-row cage mills.

Multi-row mills consist of at least two cages and, in most cases, an even number of rows (two, four, or six). A multi-row cage mill has multiple stages of impact reduction, which produces size reduction by adding energy to the feed. The material enters the center of the innermost cage, where it bounces around, getting struck until its small enough to exit that row. Particle impact velocity increases the farther from the center the material travels.

Two-row and four-row cage mills output smaller mesh gradations than a single-row cage mill because they impart more energy into the material. Typical applications include distillery and brewery grain grinding, potash, glass, salt, gelatins, foundry cores, and potassium chloride.

By changing the speeds of the cages, the same multi-row cage mill configuration can produce a variety of different-sized final products from coal, oat hulls, sugar, oyster, clam, and seashell feeds.

Six-row cage mills are a unique solution for fine grinding of calcium carbonate, talc, cosmetic powders, and kaolin clay. Understanding the hardness and chemistry is a crucial application qualifier. The six-row is the final option before getting into higher cost, specialized fine or ultra-fine grinding equipment, such as ball mills, vertical roller mills, or jet mills. Final crushed product sizes down to 80% passing 200 mesh are possible.

Cage Mill Maintenance

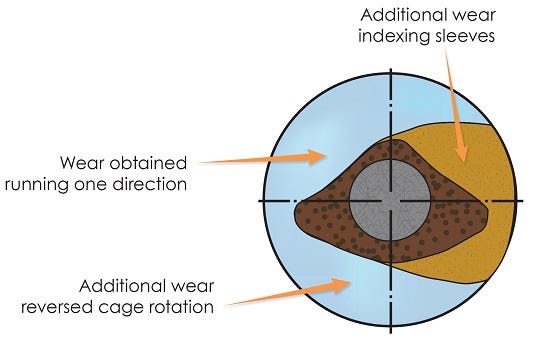

Cage configuration controls the feed's flow through the machine. The design concentrates the wear on the pins, which are made of hard alloys, to maximize the life span before replacement.

Here's what you need to know to increase the life of the cage sleeves: Reverse the rotation of cages frequently, allowing the sleeves to wear on both sides. Indexing or rotating the sleeves 90 degrees also increases the wear surface allowing for higher utilization of the wear parts. Modern designs allow one-hour changeout with backup cages to perform maintenance without downtime.

Work with your manufacturer to define maintenance schedules for extending the life of wear parts. There are no standard schedules as a result of variations due to moisture content, mineral composites, concentration, and other variables.

Testing is a Must for Proper Application

Testing a variety of impactors and machine settings offers insight as to which mill works best. Testing at different speeds ensures meeting the right particle size reduction requirements, while keeping up with production demands.

Remember, the best results come from testing done at the specific moisture content and bulk density, as found in the field. Since changes to the material can occur during transport to the test facility, an analysis is critical to determine if any changes occurred that may affect the final test results. Abrasion tests determine wear-surface consumption and replacement schedules.

Summary

Yes, the cage mill is a different type of impact crusher. By their very design, cage mills produce results that differ from the horizontal shaft and vertical shaft impactors. Once you understand how it operates and its advantages, you will be more likely to consider testing it on your feed or for the development of a new product in an existing plant.

If you have an old cage mill that's not performing up to speed, reviewing the initial testing process and results can help get you back on track.

The cage mill is a timeless classic. The versatility of the operation makes this impact crusher a workhorse for many industrial applications. If a product needs crushing, it's probably passed through a cage mill in the last 144 years. Take your place in history by considering a cage mill in your facility.

Eric Marcotte is director of units and systems sales, Stedman Machine Co. (Aurora, IN). For more information, call 812-926-0038 or visit www.stedman-machine.com.

Here are size reduction-related articles that may interest you:

Identifying a Pin Mill for Optimal Performance and Minimal Downtime

Tech Talk: Hammer Mills and the Attrition Zone

Customized Lump Breaker Solves Process Line Challenges

You May Also Like