Pneumatic Conveying and Sterile Manufacturing

February 14, 2020

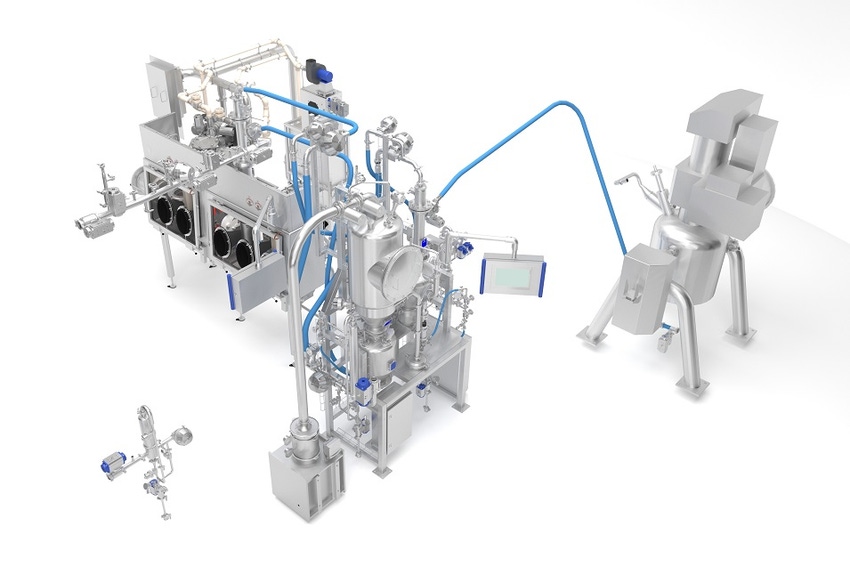

Sterile powder conveying is now possible with the aseptic version of the versatile PTS Powder Transfer System. This allows the user to link the process steps and run a fully closed operation in a controlled manner.

Sterility assurance is of paramount importance in aseptic manufacturing where product contamination may have severe consequences for both the producer and the end-user.

In a recent project where sterility was to be maintained throughout all working steps, the process encompassed filter dryer discharge by PTS into intermediary hoppers to feed the jet milling process and again PTS transfer into a dispensing and packing isolator, where the bags are finally welded and leave the isolator through a continuous liner system.

PTS guarantees product integrity during the transfers and is designed for SIP (sterilization-in-place).

Dec Group, Ecublens, Switzerland +41 (21) 694 20 40 www.dec-group.net

Here are more articles that may interest you:

Smart Conveyors Promote Productivity

Why Pneumatic Conveying Best Satisfies the 6 Additive Manufacture Powder Handling Requirements

Pneumatic Conveying through Inclined Pipe

Supply Meets Demand with Continuous Powder Processing System

How to Determine the Best Pneumatic Conveying Method for Handling Blended Powders

You May Also Like