Technology Review 1720

March 16, 2011

Grade 5 Elevator Bolts

Grade 5 Elevator Bolts

Tapco has added IFI Grade 5 No. 1 Norway flat countersunk head elevator bolts to its existing product line. The Grade 5 elevator bolts have greater proof load, minimum yield strength, and minimum tensile strength than traditional Grade 1 or Grade 2 bolts -- allowing them to better withstand the additional forces exerted on elevator belt lap splices or other heavy-duty applications. The bolts are supplied with a distinguishing yellow zinc-plated (CR3) coating and SAE grade marking, in 14 sizes ranging from ¼-20 x ¾ in. to 3/8-16 x 2 in. Tapco Inc., St. Louis, MO 800-288-2726 www.tapcoinc.com

Sifter with Portholes

Sifter with Portholes

An inspection porthole is now available on CS-1 gyratory sifters that allows easy access to visually inspect 100% of the screen area without the need to disassemble the sifter. The view port is easy to use and requires no tools. You simply unscrew two wing nuts and remove the metal cover plate. The optional view port is available on select decks for the CS-1 sifter and includes front and rear side portholes with cover plates, self-adhering gaskets for the cover plates, and nylon wing nuts. Existing CS-1 sifter decks can be retrofitted during the repair process. The inspection porthole facilitates maintenance and sanitation as well as helps to extend the life of the gaskets and decks. Sifter Parts & Service Inc., Wesley Chapel, FL 800-367-3591 www.sifterparts.com

Lab Air Classifier Mill

Lab Air Classifier Mill

The PPS lab air classifier mill is specifically designed to produce laboratory samples with the same particle size and characteristics attained from the full production air classifier mills. Produced in high-quality stainless steel, the system consists of a feed system, grinding mill, collection cyclone, filters, and system fan. It is equipped with a fully automatic interlocked control panel ensuring safe and easy operation. The PPS Lab air classifier mill is capable of handling an extensive range of materials with constantly changing product specifications. Kemutec, Bristol, PA 215-788-8013 www.KemutecUSA.com

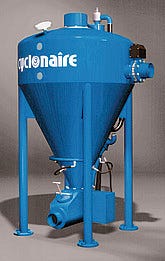

Dense-Phase System

Dense-Phase System

The dense-phase BlendVeyor system combines automatic batching, blending, and conveying of dry bulk solids from multiple sources in programmed ratios by weight. These new systems convey at low line velocities and high material-to-air ratios to minimize product degradation and line wear. While built-in load cells weigh ingredients as they are added, an easy-to-program touch-screen controller monitors ingredient loading and adjusts flow to achieve the desired ingredient weights. When all ingredients have been added, the controller automatically initiates the blend sequence and then cycles the unit for conveying the recipe to a mixing station or to packaging or load out. Cyclonaire Corp., York, NE 888-593-6241 www.cyclonaire.com

BC Cleaning System

BC Cleaning System

This IBC cleaning system can wash two IBCs simultaneously. Design features of this system include: a complete utility control system to store water, heat to specified set point, and cool drain water—needed because very hot water will upset customer’s in-house wastewater treatment process; pass through design—soiled IBCs enter one door and clean exit the other; a piping system for high purity—WFI water is completely independent from potable water piping; wash station self-clean mode; a re-circulated hot air drying system that conserves energy and maintains room air balance—pulls in very little makeup air; drive in loading. CPS, Springfield, MO 417-868-8002 www.custom-powder.com

Label Printer

Label Printer

With the release of Easylabel 5 Platinum, Tharo Systems Inc. is providing a collection of tools for FDA 21 CFR Part 11 compliance, including additional password and user options, logging options, and format options. Using these tools, and based on your company’s internal requirements and those of your FDA inspector, you will be able to set up a compliant system. Easylabel 5 includes several other additions to make printing labels faster and easier. The new GS1 barcode wizard makes creating GS1 barcodes a simple 4-step process. Easylabel 5 supports Microsoft’s ActiveX Data Objects (ADO) providing a fast, easy, and productive means for accessing data sources. The new database editor uses Microsoft’s OLE DB, providing the freedom to view and edit almost any database from inside Easylabel 5. A demo is available for download. Tharo Systems Inc., Brunswick, OH 800-878-6833 www.tharo.com

Rotary Feeder Valves

Rotary Feeder Valves

Designed specifically for rugged applications and processing of harsh or abrasive materials, the CI Series of rotary feeder valves provides bulk material processing operations continuous performance, reduced maintenance, and energy efficiency. To provide long-term, heavy-duty feeder performance, the valve housings are cast in North America to ensure superior strength in the composition and solidification of the housing’s metallurgy. Bearing life and maintenance cycles are extended due to the outboard bearing design. This design easily manages applications with pressure differentials up to 15 psig. The outboard design also protects the bearings in high-temperature applications to 750ºF, and removes bearings from the path of damaging and contaminating materials. The 8-vane rotor design improves process energy efficiency by minimizing pressure loss throughout the system. The valves’ simultaneous 2-vane inlet seal and 2-vane outlet seal maintains accurate pressure differentials, reducing compressed air requirements. ACS Valves, North Caledonia, ON, Canada 800-655-3447 www.acsvalves.com

Filter Cake Drying System

Filter Cake Drying System

This drying system uses RF energy to uniformly heat filter cake material and rapidly remove the water without overheating, at a fraction of the time and expense associated with conventional dryers. The Macrowave RF drying system rapidly removes water from filter cake material using energy applied by radio waves at a frequency of 40.68 MHz. Featuring volumetric heating that provides instantaneous and uniform heating throughout the filter cake and prevents overheating, the drying system is available in both batch and conveyorized configurations. Eliminating the long dwell time required by conventional surface heating methods, the system is a suitable replacement for tumble-, spray-, tray-, spin flash-, and belt/tunnel dryers. Radio Frequency Company, Inc., Millis, MA 508-376-9555 www.radiofrequency.com

Cable and Chain Driven Tubular Drag Conveyors

Cable and Chain Driven Tubular Drag Conveyors

Two types of tubular drag conveyors have been added to Spiroflow’s range of conveyors. They include the new CABLEflow tubular drag conveyor and the Dynaflow tubular chain drag conveyor. CABLEflow tubular drag conveyors are a development of aero mechanical conveyors, operating with reduced clearances and reduced running speeds. The new line of conveyors is designed for gentle handling applications and installations requiring conveying in multiple planes. They can transfer friable bulk products from single or multiple in-feed points to single or multiple discharge points with little or no damage. The Dynaflow tubular chain drag conveyor range is also a mechanical drag conveyor system operating within the confines of a pipe. However, the discs that move material along the pipe are heavy-duty discs connected by articulated metal links (chains) that equip them for heavy-duty applications. Spiroflow Systems Inc., Monroe, NC 704-291-9595 www.spiroflowsystems.com

FIBC Filling System

FIBC Filling System

This high-output filling system offers patented technology including a horizontal pivoting and rotating bag fill carriage for rapid and ergonomic operator connection of bulk bags. After bag connection, the bulk bag is automatically inflated, filled by weight to a programmed set point, and densified. Once the fill cycle is complete, the bag inlet spout and straps release, the fill head raises, and the filled bag is automatically indexed out of the filling station. Allen-Bradley PLC controls with a color PanelView operator interface provide easy access to system status, recipes, and operational parameters. Systems are custom designed to application requirements. Material Transfer & Storage, Allegan, MI 800-836-7068 www.materialtransfer.com

Palletizer with Fully Integrated Stretch Wrapper

Palletizer with Fully Integrated Stretch Wrapper

The Model FL1000-SW combines a rugged, heavy-duty small footprint palletizer with the added functionality of a fully integrated stretch wrapper. Requiring no modification, the FL1000-SW can simultaneously stack and stretch wrap a wide variety of package types including cases, trays, totes, film only, and display packs for a variety of industries including canned and frozen foods, beverage, pharmaceutical, and more. It includes formed and welded steel construction and 80-pitch hoist chain. Columbia Machine Inc., Vancouver, WA 800-628-4065 www.palletizing.com

Cone-Bottom Silo Reclaim Systems

Cone-Bottom Silo Reclaim Systems

The 9300 Series cone-bottom silo reclaim systems provide a solution to bridging and hang-up problems. They are ideal for extreme-duty applications in materials with poor flow characteristics or where safety regulations require full maintenance from outside the silo. This cone bottom silo reclaimer is engineered for 24/7 operation. The rugged sweep auger rotates 360º around the bin, helping to create mass flow, and providing delivery that approximates first-in-first-out (FIFO) inventory control. The unit can be customized to handle a wide variety of materials, including grain meals, powders, chemicals, wood chips, saw dust, and re-cycled materials. It is available in diameters up to 45 ft, and is provided in steel tanks, concrete silos, or corrugated bins, with cone bottoms ranging from 30 to 60º. Laidig Systems, Mishwaka, IN 574-256-0204 www.laidig.com

You May Also Like