Mixing & Blending Spotlight - December 2010

December 13, 2010

Double Planetary Mixer and Discharge System

Double Planetary Mixer and Discharge System

This company recently completed a new design variation of the double planetary mixer and follower plate discharge system. The double planetary is typically used for the mixing and dispersion of viscous materials. The follower plate discharge system is then used to press viscous non-flowing materials from the planetary mixer mixing vessel after the mixing cycle is completed. The new design combines the two on a common base. This configuration permits the easy movement of the mix can to the discharge platen, after completion of the mixing cycle. In addition, the common base is elevated to allow for discharge to subsequent processing equipment or directly to packaging containers. The two machines can be customized to meet a variety of process requirements including vacuum operation, jacketing of the mix can and discharge platen, metering systems, etc. Charles Ross & Son Co., Hauppauge, NY 800-243-7677 www.mixers.com

Click to enlarge

Fluidizing Paddle BlenderThe OptimaBlend fluidizing paddle blender is a balance of mixing speed and efficiency with low equipment cost and consumed power. Traditional ribbon blender applications will benefit from increased capacity in the same space. Difficult and diverse ingredients can now be mixed quickly with high efficiency. The unit offers: mixes five times faster than a ribbon blender; high mix efficiencies with low co-efficient of variation (CVs); homogenous mixes independent of large range of particle size, shape, or density; high throughput rates with low horsepower; fluidizes powders quickly and efficiently; less degradation than ribbon blenders; efficient liquid addition; easy clean-out; low heat generated due to friction. American Process Systems, Gurnee, IL 847-336-2444 www.americanprocesssystems.com

Mixers and Blenders

Mixers and Blenders

APEC’s mixing and blending technology combines fast and gentle mixing with precise measurement and advanced automation techniques, to assure a consistent and accurate mix. Units are available in a variety of sizes in mild or stainless steel with standard or food grade construction. Ribbon mixers use a double ribbon agitator mounted with solid spokes to a solid shaft to simplify maintenance and are available in both slide gate and drop bottom designs. Continuous blenders offer low RPM low shear and are extremely gentle on extruded or pelleted products. APEC USA, Lake Odessa, MI 616-374-1000 www.apecusa.com

Click to enlarge

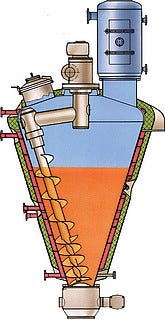

Vertical Cone Orbiting Screw MixersThese conical mixers are designed for processing all types of powders, pastes, slurries, granules, pellets, and other materials in the pharmaceutical, food, chemical, and many other industries, delivering the greatest flexibility for the most diverse types of products to be mixed or dried. Typical tasks such as mixing/blending, liquid or gas injection into the batch, and drying can be carried out with absolute precision. It is also possible to perform multiple automated processing tasks simultaneously in a single piece of equipment in a fully safe and enclosed vessel. Bolz-Summix, Swedesboro, NJ 856-241-9970 www.bolz-summix.com

Conical Screw Blender

Conical Screw Blender

This conical screw blender is used for mixing and blending powders in the chemicals, petrochemicals, pharmaceuticals, food, cosmetics, and plastics industries. Conical screw processors can be supplied in carbon steel, stainless steels, and other exotic alloys. Sizes are available from 2 to 2650 cu ft. The blender has a tapered screw as standard construction. The tapered screw is more efficient than the straight screw. This design reduces the total overall height, decreases the blending time, and improves the efficiency of the mixer. A retrofit drive unit is offered to replace older designs. Jaygo Inc., Union, NJ 908-688-3600 www.jaygoinc.com

Click to enlarge

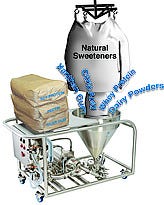

Powder Induction and Dispersion SystemThe Fastfeed powder induction and dispersion system is designed to offer controlled powder feed rates from 3 to 400 lb/min. It offers consistent powder delivery even as viscosity and solids levels increase, ensuring that the system will never plug or foul. It offers the benefits of an inline, skid-mounted dispersion system that feeds powders and disperses them instantly. It further allows processors to add dry ingredients to mix vessels in a more ergonomic fashion, reducing operator injuries and provides the shear required for today’s changing and tougher ingredients insuring maximum yield. Admix Inc., Manchester, NH 603-627-2340 www.admix.com

Continuous Loss-in-Weight Blender

Continuous Loss-in-Weight Blender

The AccuMeter Series is designed to blend a wide range of materials in continuous extrusion applications and offers a more homogenous blend than batch-type blenders, feeders, or mixers. The feeders are mounted on precision load cells, continuously weighing the output of each component. The material flow is constantly monitored; any changes in properties such as bulk density, pellet size, etc., are compensated for, and have no effect on the accuracy of the blended material. This system will improve overall product quality and reduce material usage caused by over-feeding, resulting in reduced product costs. Colortronic North America Inc., Flint, MI 810-720-7300 www.colortronicna.com

Click to enlarge

Gravimetric Batch BlendersThe new design of Guardian Series 2 provides precise batch-to-batch dispensing and consistent homogenous blending. New standard features include B&R controls, color touch-screen, removable cartridge V-gate metering, segmented material hoppers, integral drain chute, and a �“no dead zone” mixing chamber. The units may be configured with 4 to 12 ingredient hoppers, with each hopper capable of running 0-100% of the recipe with dispensing accuracy up to +/-0.02%. There are four models, including 1.25/2.5, 5, 12, and 18/25 kg, with throughput rates to over 5000 pph. Process Control Corp., Atlanta, GA 770-449-8810 www.process-control.com

Mixers and Blenders with Cantilever Shaft

Mixers and Blenders with Cantilever Shaft

This full range of Gardner mixers and blenders featuring the Easy-Clean cantilever agitator shaft that eliminates one set of bearings and seals at the non-drive end of the shaft. This, along with the full diameter hinged and safety, interlocked door improves access for cleaning and hygiene. The completely contained mixing media provides an ideal environment for dry, semi-dry, or moist powder applications. Units are available in various designs with a choice of a plough, paddle, or interrupted spiral agitator. Also available are double cone blenders, continuous mixers, stirred bunkers and processors, and reactor mixers. Kemutec, Bristol, PA 215-788-8013 www.KemutecUSA.com

Click to enlarge

Double-Shafted Fluidized Zone MixerThe Bella XN double-shafted fluidized zone mixer includes access doors that not only increase accessibility but also make it easier to clean when necessary. The mixer achieves fast, high-capacity, low-shear, precision mixing of either dry bulk solids or liquids with solids. Regardless of particle size, shape, or density, materials are mixed with a fast, efficient, and gentle action, with typical mixing times 60 seconds or less. A weightless zone created by low-speed counter-rotating shafts generates low friction without shear, making it ideal for fragile products that cannot tolerate rough handling. Even flakes or spray-dried bodies remain intact. The mixer includes twin bomb-bay door openings for fast, efficient discharging and to minimize segregation during discharge. The unit is available in stainless steel for sanitary applications. Custom sizes, finishes, and materials of construction are available upon request. Dynamic Air Inc., St. Paul, MN 651-484-2900 www.dynamicair.com

Batch Mixer

Batch Mixer

Mixing applications that require a thorough blending of ingredients can make use of this batch mixer with intensifiers. The intensifiers act as “choppers” that break up clumps that form in a batch. The intensifiers complement the agitator when blending, as well as reduce the blending time of minor ingredients. Various intensifier designs are available in addition to the standard tulip blade design. Intensifier selection depends on the ingredient characteristics. Lab testing is recommended in order to determine the optimal configuration. S. Howes, Silver Creek, NY 716-934-2611 www.showes.com

Click to enlarge

Mixer and Jacketed Vacuum DryerThis Easy Clean design is available for batch or continuous material processing. Features include: large access doors for full access to the vessel interior; vessel designed and constructed for full vacuum operation; a fully stayed, 90 PSIG @ 330°F, ASME code constructed, 304 stainless steel jacket of labyrinth design to ensure uniform flow for heating and/or cooling; simplifies the task of cleaning difficult applications; reduces downtime for cleaning; provides better discharge capabilities with optional dual discharges or oversize discharge doors; provides a better solution that addresses cross contamination. Littleford Day Inc., Florence, KY 800-365-8555 www.littleford.com

Sanitary Rotary Batch Mixer

Sanitary Rotary Batch Mixer

The 700-TH-40-SS sanitary rotary batch mixer gently blends batches of ingredients in parts down to one per million with 100% uniformity in less than three minutes, evacuates 100% of the batch, and sanitizes rapidly with no tools. It has a useable capacity of 40 cu ft and is equally effective blending 100 down to 5 percent of rated capacity. Intended for 3-A, USDA, and contamination-sensitive industrial applications, and/or frequent product changeovers, the mixer features stainless contact surfaces, continuous polished welds, external removable seals, and a CIP vessel cleaning nozzle. It is equipped with a spray line for liquid additions. Munson Machinery Company, Inc., Utica, NY 800-944-6644 www.munsonmachinery.com

You May Also Like